Aqueous cutting fluid for use with diamond wiresaw

A cutting fluid and wire saw technology, applied in the field of water-containing cutting fluid, water-containing cutting fluid for brittle materials), can solve the problems of frequent replacement of cutting fluid, nozzle blockage, etc., to achieve good cooling efficiency, easy removal, good chip suspension and dispersion effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

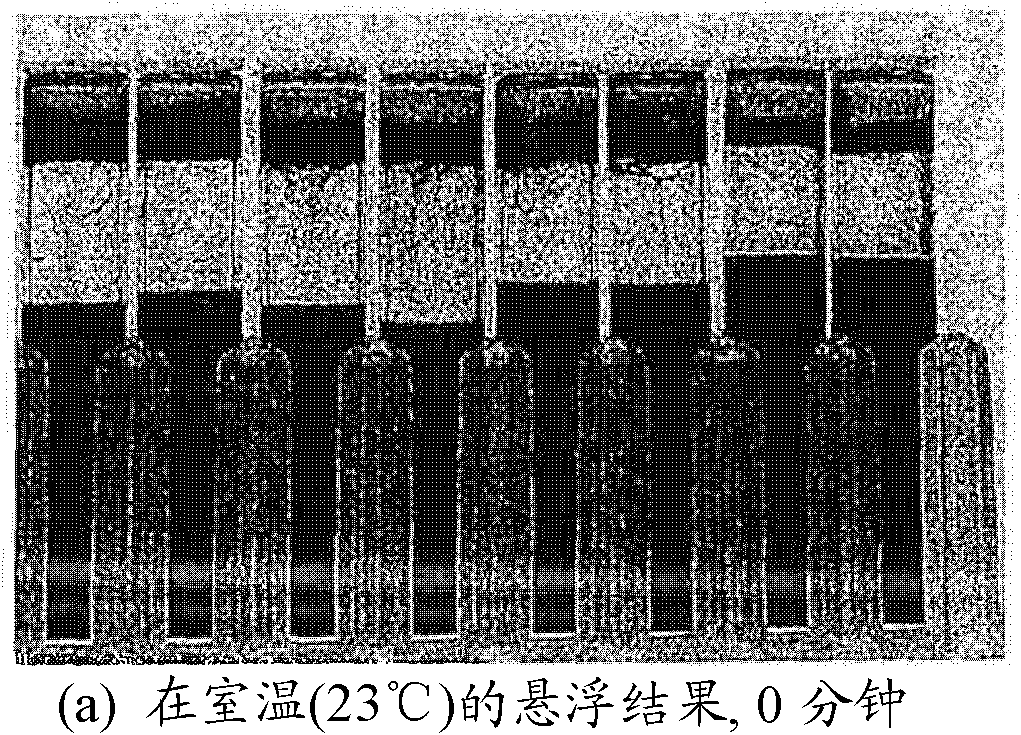

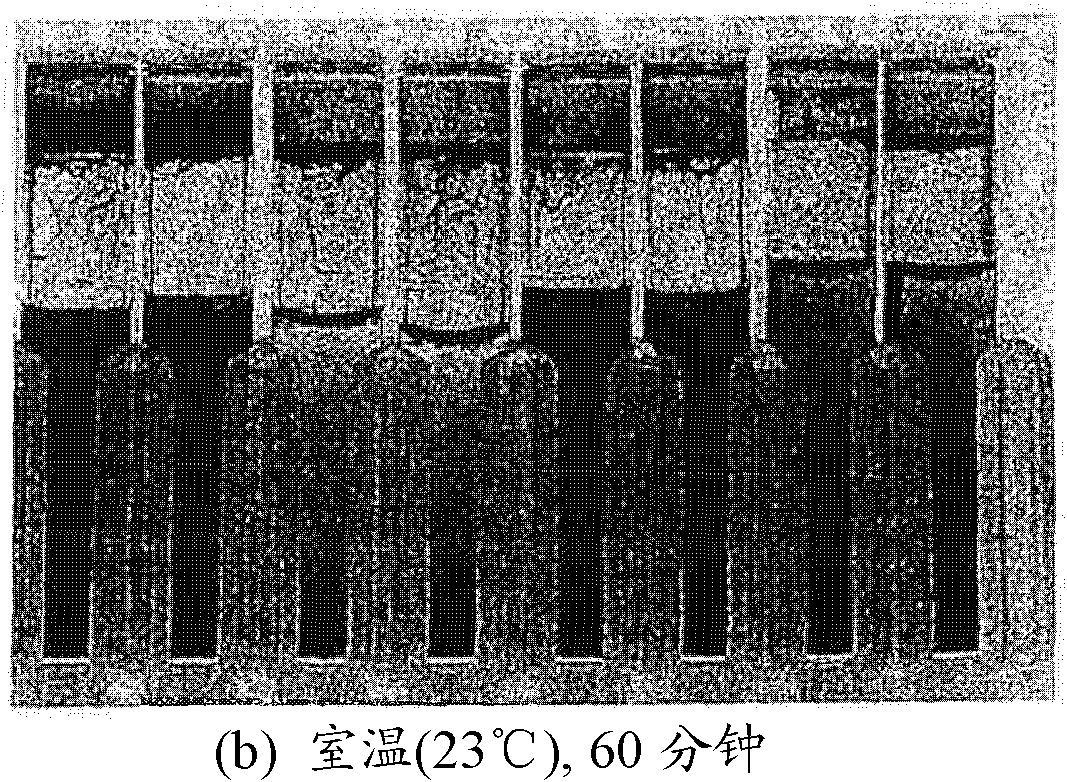

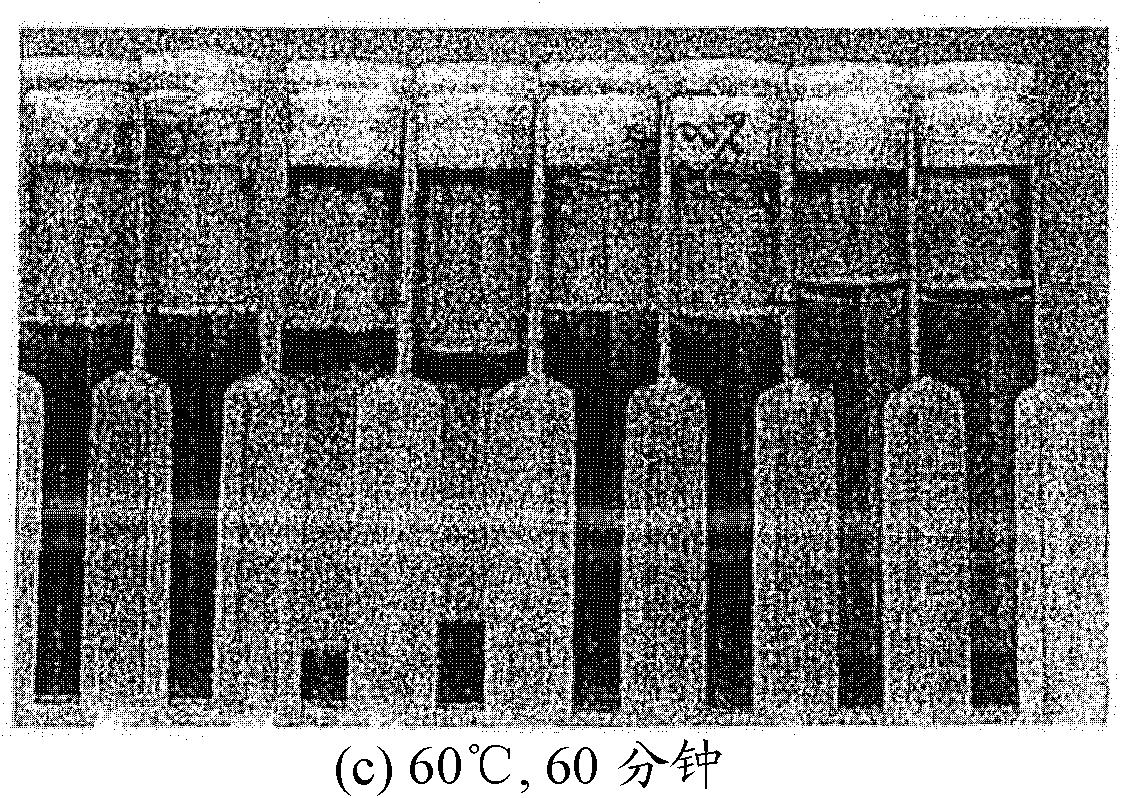

Image

Examples

Embodiment approach

[0089] Chemicals and Instruments

[0090] The cutting fluid of the present invention is prepared from the components described in Table 1, and its composition is recorded in Table 2. The cutting fluids of the comparative examples are all commercially obtained. None of the cutting fluids of the comparative examples included PAG-g-polycarboxylate.

[0091] Table 1

[0092] Components and Equipment

[0093]

[0094] Table 2

[0095] The composition of cutting fluid of the present invention

[0096] components

[0097] PEG-g-polycarboxylate

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com