Photovoltaic inverter

A photovoltaic inverter and transformer module technology, applied in the field of inverters, can solve problems such as assembly confusion, affecting the normal operation of inverters, and mutual interference, and achieve the effects of easy assembly and maintenance, neat assembly, and low mutual interference

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

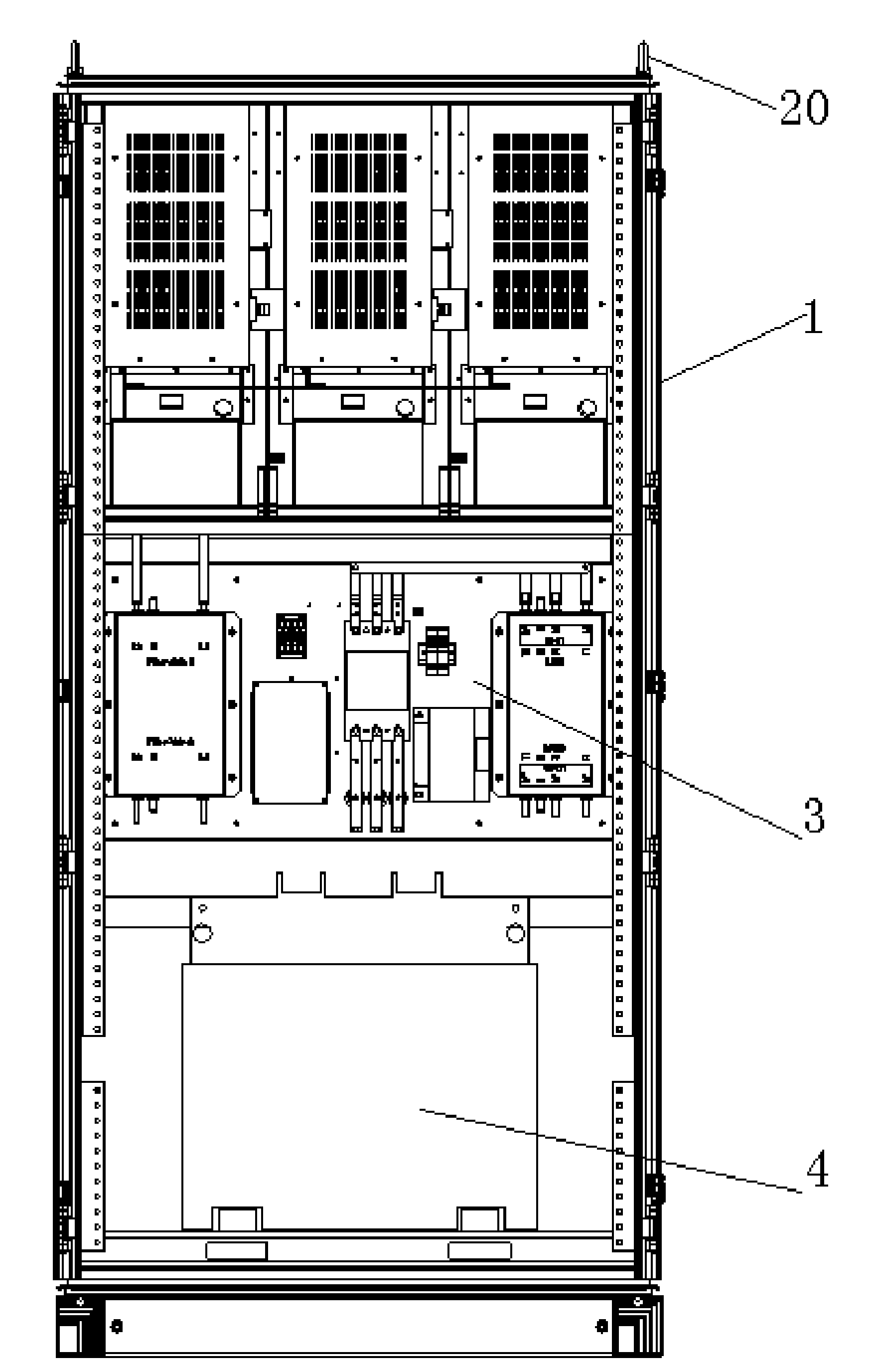

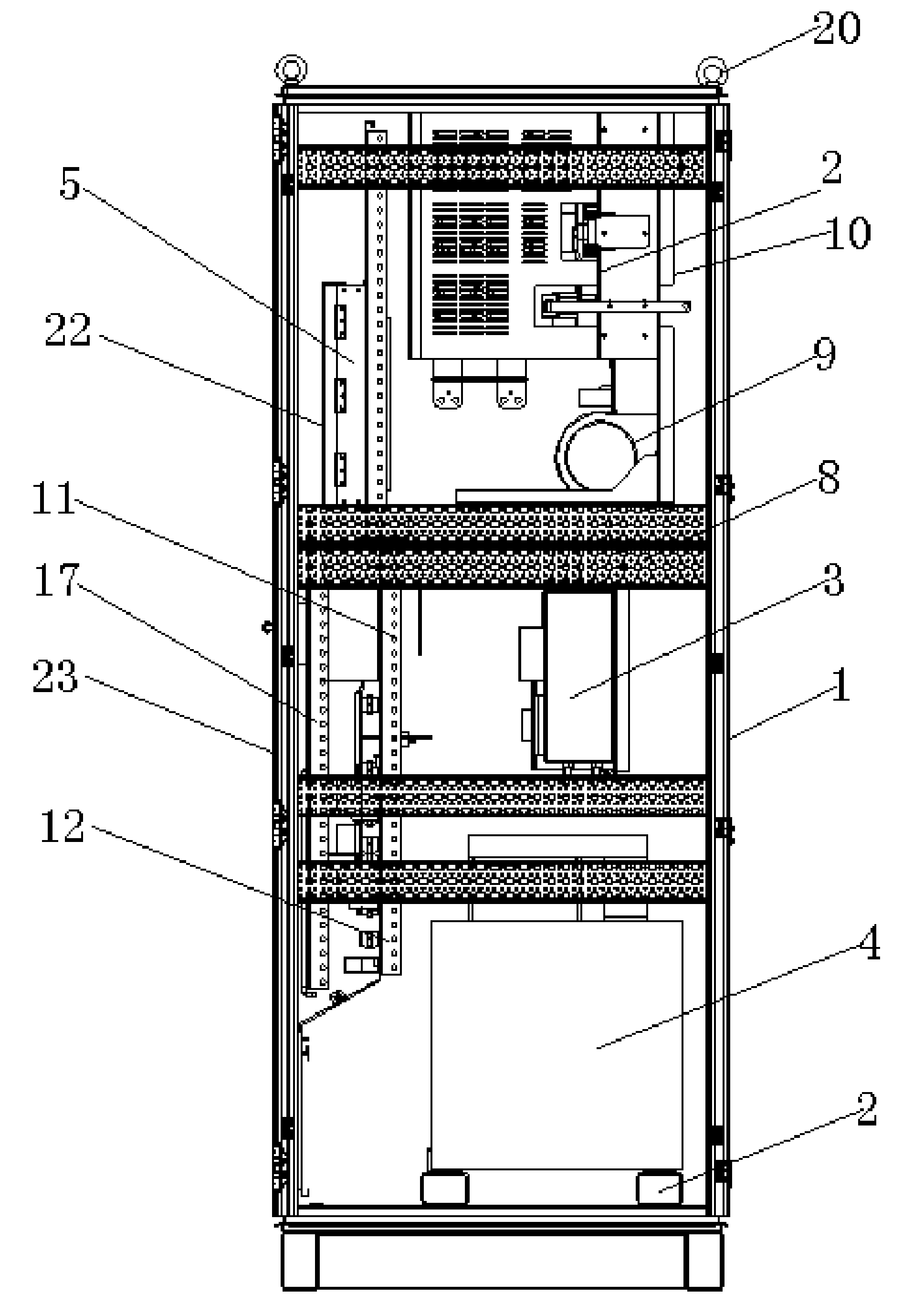

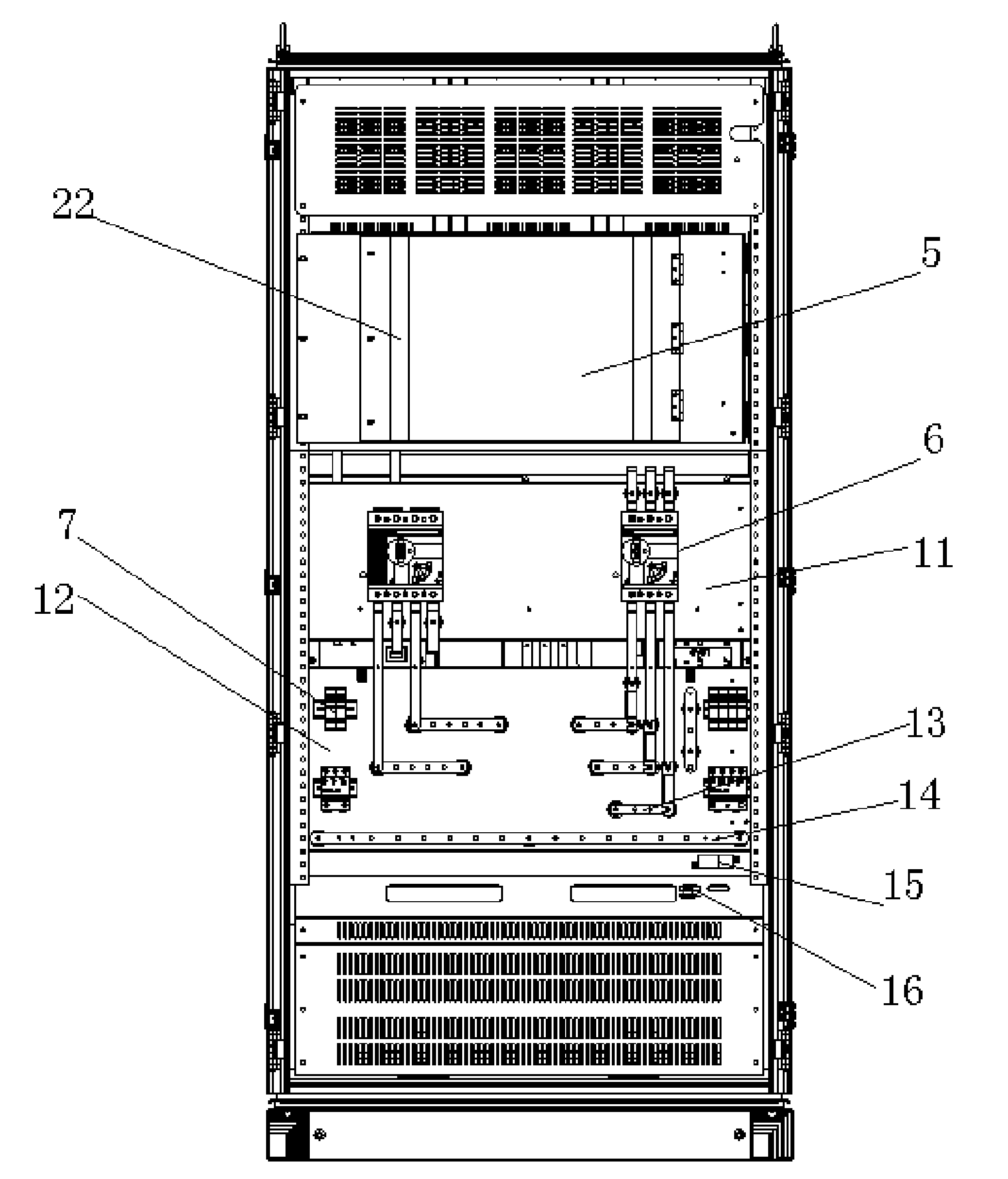

[0021] refer to Figure 1 to Figure 5 A photovoltaic inverter is shown, which includes a cabinet 1, a power module 2 arranged in the cabinet 1, a filter module 3, a transformer module 4, a control board module 5, a circuit breaker 6 and a contactor 7, the cabinet The body 1 is provided with a number of beams 8 for supporting and fixing the power module 2, the filter module 3 and the transformer module. Above the transformer module 4, the power module 2 and the control board module 5 are arranged at the top inside the cabinet body 1, the power module 2 is arranged on the power module fixing panel 10, the lower end of the power module 2 is provided with a radiator 9, and the power module fixing panel 10 is fixed on the power module fixing beam 8 in the cabinet 1, the control board module 5 is set in front of the power module 2 in the cabinet 1, and the filter module 3 is set on the filter module 3 fixing beam 8 below the power module 2 Above, the circuit breaker 6 is set on the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com