On-line measuring device for frictional force generated during polishing of small-sized wafer

A measuring device and friction force technology, which is applied in the direction of grinding/polishing equipment, surface polishing machine tools, semiconductor/solid-state device testing/measurement, etc., can solve the problems of high precision of measuring devices, small friction, covering, etc., and achieve measurement High precision requirements, avoiding measurement errors, and high measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

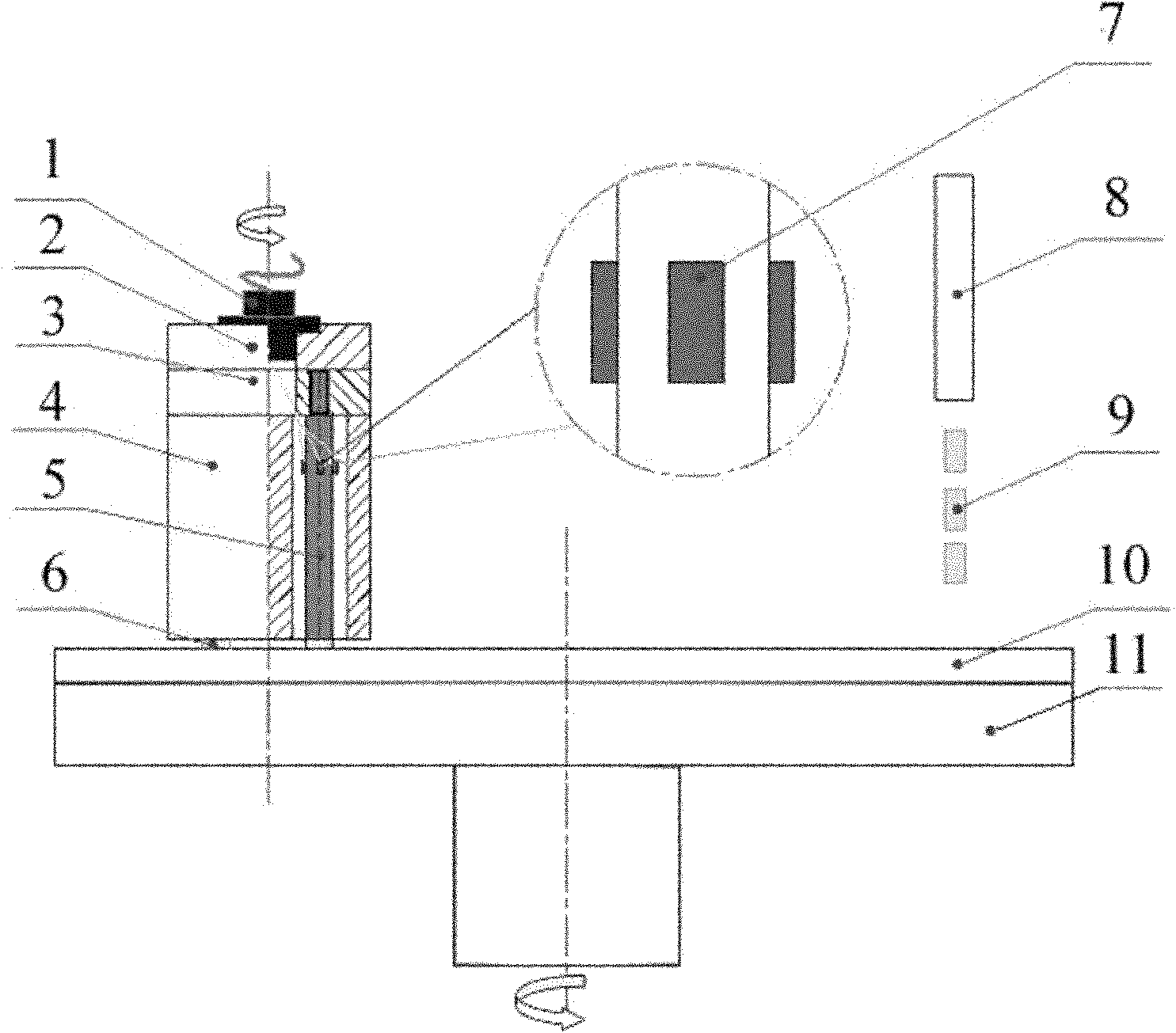

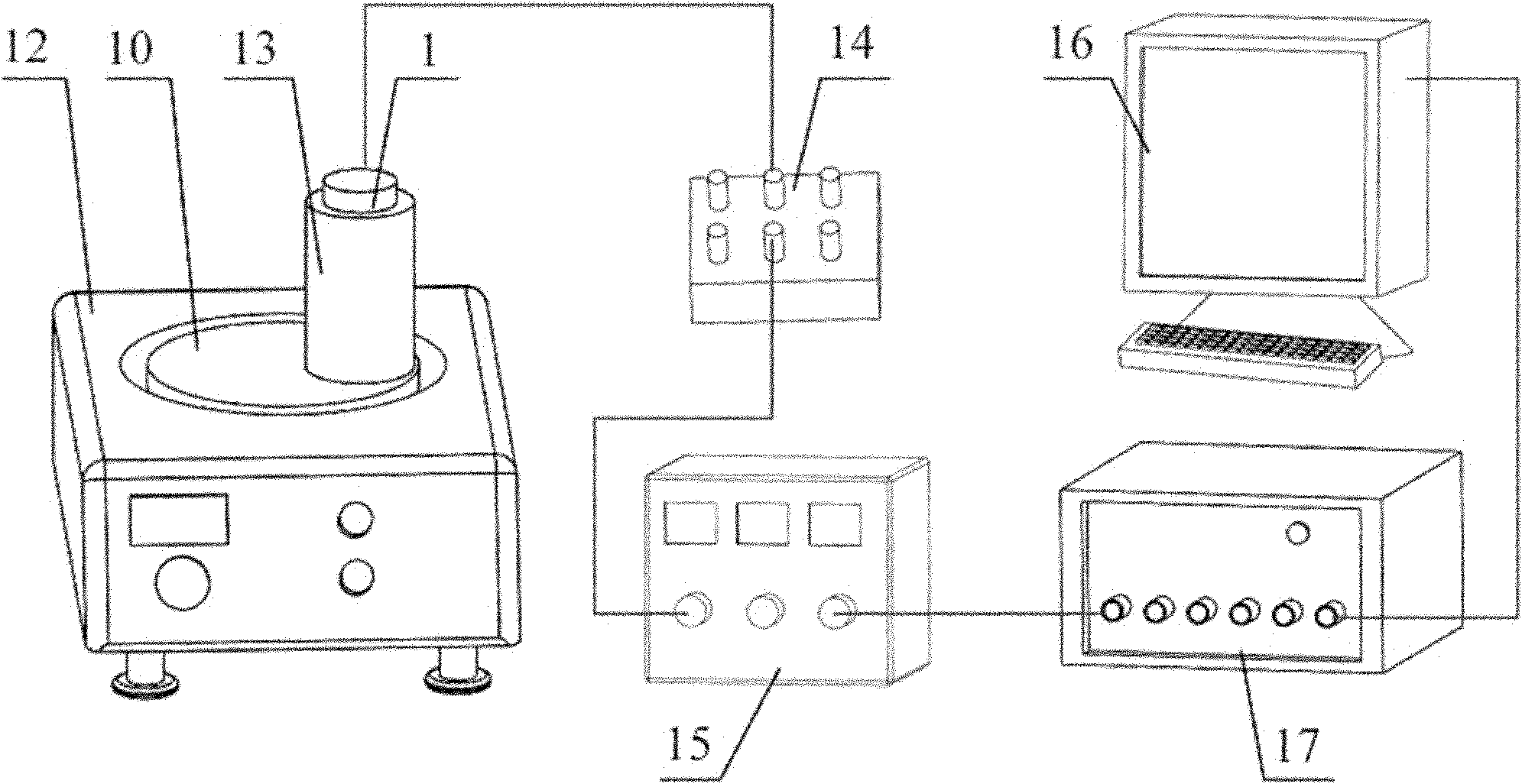

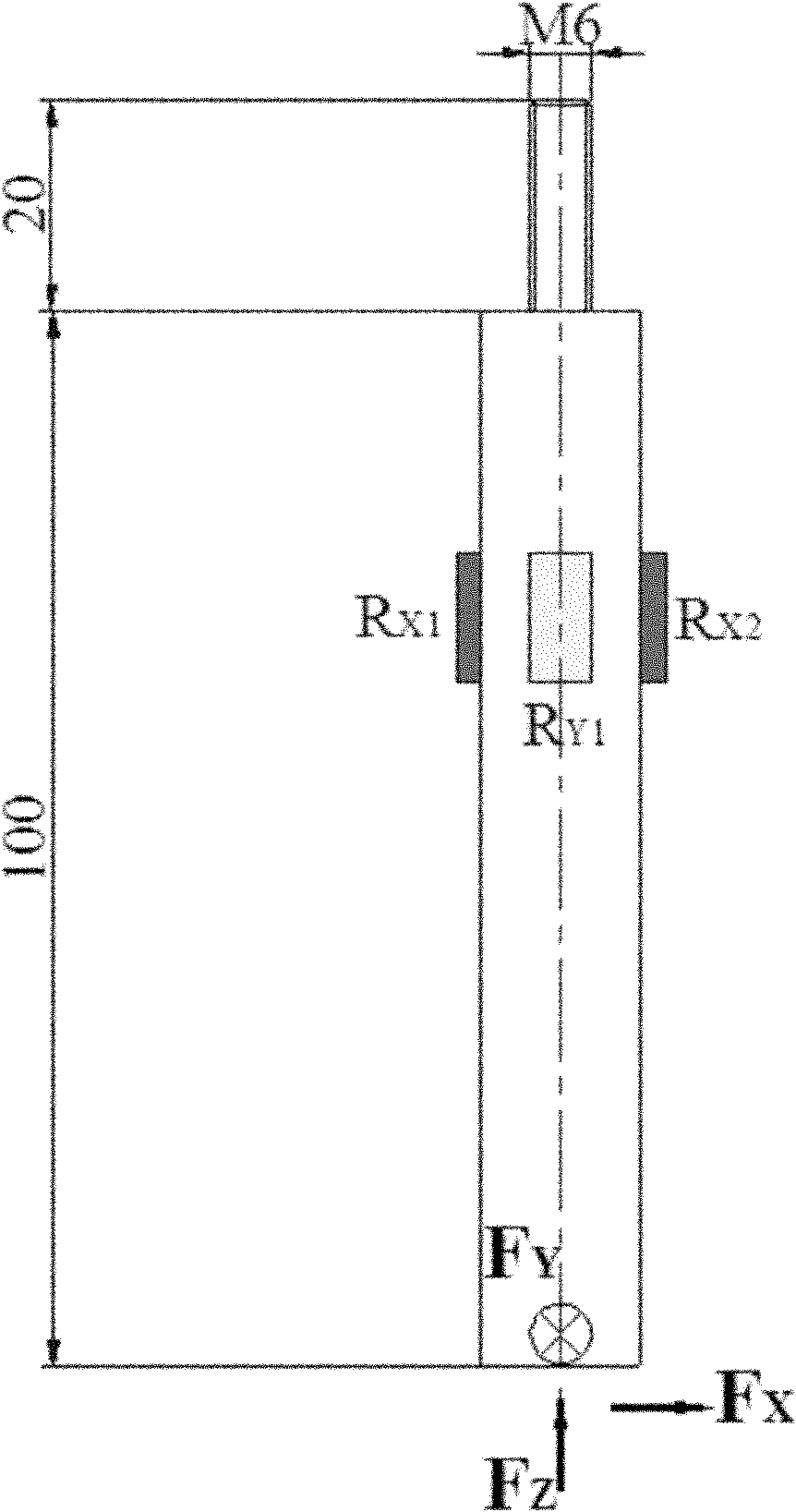

[0018] as attached figure 1 As shown, the structure of the polishing head mainly includes a slip ring 1 , a counterweight A2 , a counterweight B3 , a counterweight C4 , an elastic element 5 , a chip 6 , and a strain gauge 7 . The counterweight C4 has a diameter of 100 mm and a length of 100 mm. A light hole with a diameter of 20mm is processed on it. Process the M6 threaded hole on the counterweight B3, and the threaded hole is coaxial with the light hole of the counterweight C4. Different polishing pressures can be realized by adjusting the number and height of the counterweight B3. The elastic element 5 is made of aluminum alloy and has a length of 120 mm. The diameter of the lower cylindrical part is 15mm, and the length is 100mm, and the upper end is an M6 thread, and the length is 20mm. Put the elastic element 5 into the hole of the counterweight C4, and fix it on the counterweight B3 through the thread of M6. During the assembly process, ensure that the cylindrica...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com