System for automatically testing computer mainboard

An automatic test system and computer technology, applied in the detection of faulty computer hardware, etc., can solve the problems of factory operators' management troubles, waste of manpower and material resources in the factory, lack of operating standards, etc., to save manpower configuration and misjudgment, improve Work efficiency and the effect of shortening test time

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

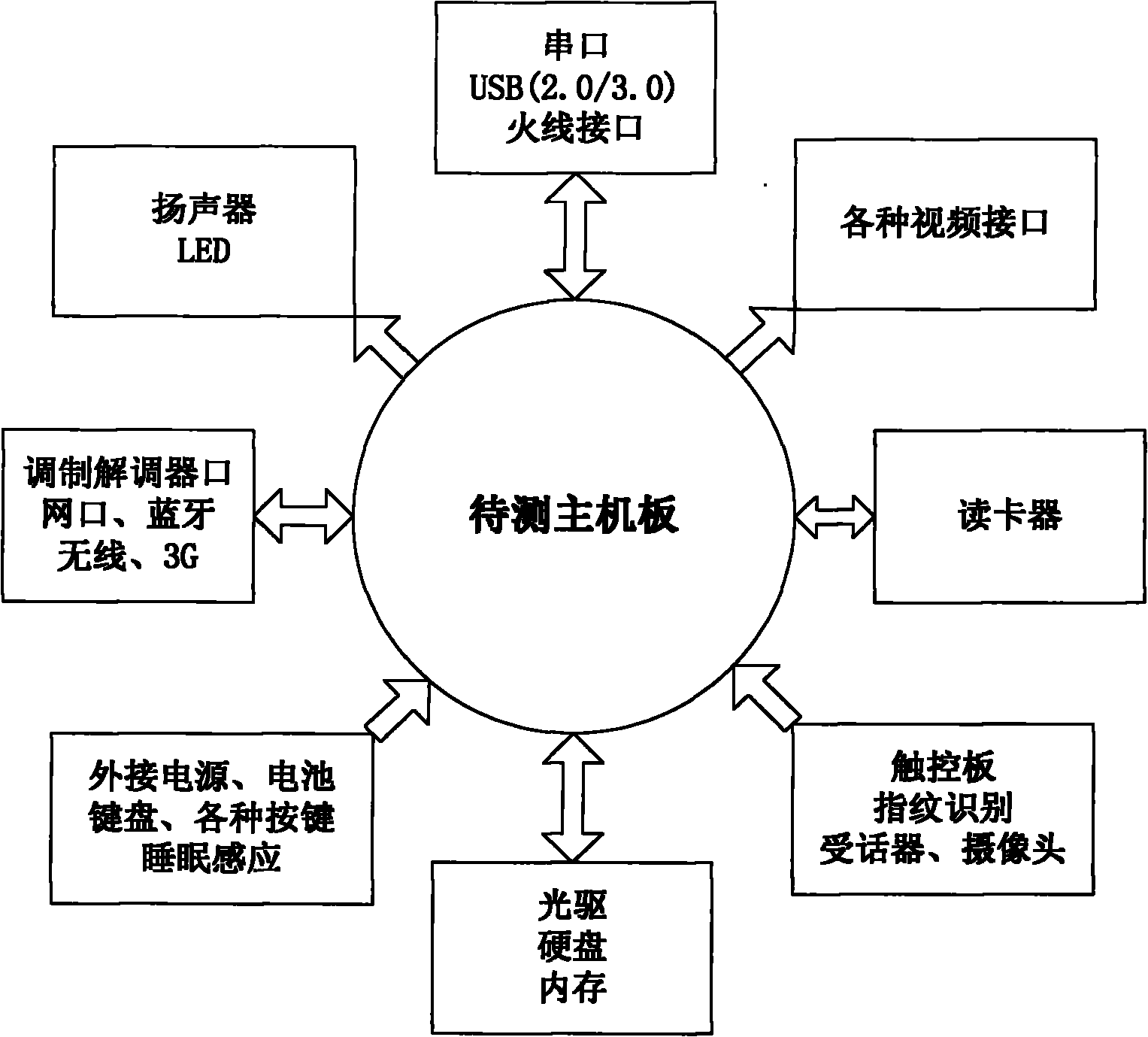

[0035] see figure 1 , computer motherboard automatic test system, including a signal processing module 1, a display unit 2, a sending module 3, a receiving conversion module 4 and a mainboard 5 to be tested.

[0036] The signal processing module 1 is respectively connected with the display unit 2, the sending module 3 and the receiving conversion module 4, wherein the output end of the signal processing module 1 is connected to the display unit 2, and the input end of the sending module 3 is connected to the The output end of the signal processing module 1 is connected to the motherboard 5 to be tested; the input end of the receiving conversion module 4 is connected to the motherboard 5 to be tested, and the output end is connected to the signal processing module 1 .

[0037] The display unit 2 converts various video signals into VGA signals through a video converter, and then detects the quality of the signals through a third-party dedicated video detection device. This metho...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com