Method for preparing paper making wet end chemical addition agent by using cassava residue as raw material

A technology of chemical additives and cassava residues, which is applied in the direction of adding retention aids, etc., can solve the problems of unreported application examples, limited consumption, environmental pollution, etc., and achieves wide application range, wide PH value application range, and simple preparation process Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

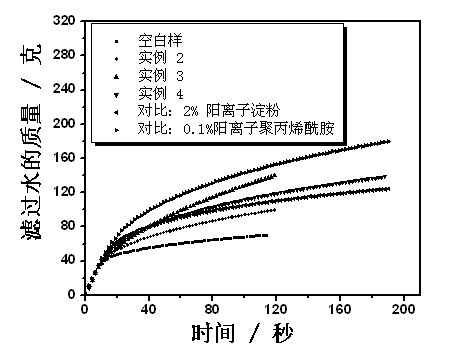

Image

Examples

Embodiment 1

[0030] (1) Disintegrate the wet cassava slag from the factory, wash and disperse it with clean water, and then sieve to remove the mixture composed of cassava skin and suspended coarse fibers; dehydrate the remaining settled cassava residue and fine fibers and keep them for use as sediment; After the mixture is dried and dispersed, the crude fiber is separated by winnowing; the sediment is mixed with the separated crude fiber, which is the coarsely selected cassava residue;

[0031] (2) After washing the coarsely selected cassava residue, prepare cassava residue slurry with a concentration of 7%. At 30°C, keep stirring while adding sodium hypochlorite with an available chlorine content of 3% and peroxide with a mass concentration of 2.5%. Hydrogen treatment, adding sodium hydroxide to adjust the pH of the slurry to 10, the treatment time is 30min;

[0032] (3) Use dilute hydrochloric acid to neutralize the slurry treated in step (2) to neutrality and wash it. After sieving wit...

Embodiment 2

[0037] (1) Disintegrate the air-dried cassava slag, wash and disperse it with clean water, sieve to remove the cassava skin; sieve to remove the mixture composed of cassava skin and suspended coarse fiber; dehydrate the remaining settled cassava residue and fine fibers Retaining is the sediment; the mixture is dried and dispersed, then winnowed and separated to obtain crude fibers; the sediment is mixed with the separated crude fibers, which is the coarsely selected cassava residue;

[0038] (2) Add the washed cassava residue into warm water to make a cassava slurry with a concentration of 10%. While keeping stirring, add sodium hypochlorite and hydrogen peroxide in turn for treatment. The available chlorine content is 2%, and the concentration of hydrogen peroxide is 3%. , add sodium hydroxide to adjust the pH of the slurry to 11, and the treatment time is 60 minutes;

[0039] (3) Neutralize the slurry with dilute hydrochloric acid until it is neutral, then wash it, sieve it ...

Embodiment 3

[0044] (1) Disintegrate the dried cassava slag, rinse and disperse with clean water, and sieve to remove the cassava skin;

[0045] (2) Add the washed cassava slag to warm water to make a cassava slurry with a concentration of 8%. While keeping stirring, add sodium hypochlorite and hydrogen peroxide in turn for treatment, in which the available chlorine content is 5%, and the concentration of hydrogen peroxide is 4%. , add sodium hydroxide to adjust the pH of the slurry to 9, and the treatment time is 60 minutes;

[0046] (3) Neutralize the slag slurry with dilute hydrochloric acid until it becomes neutral, then wash it, sieve it through 200 meshes, leave the residue, squeeze and dry it, and grind it with a ball mill for 5 hours after drying to obtain refined cassava slag powder;

[0047] (4) Mix and stir 10 g of refined cassava base slag powder and 50 ml of isopropanol evenly, preheat at 50°C for 5 minutes, add 25ml of sodium hydroxide solution with a concentration of 108g / L,...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com