Method of filling liquid sample

A filling method and a technology for covering parts, which are applied in chemical instruments and methods, biochemical equipment and methods, liquid materials, etc., and can solve the problems of affecting sample volume, increasing costs, and prone to deviations in measurement results, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

no. 2 Embodiment approach

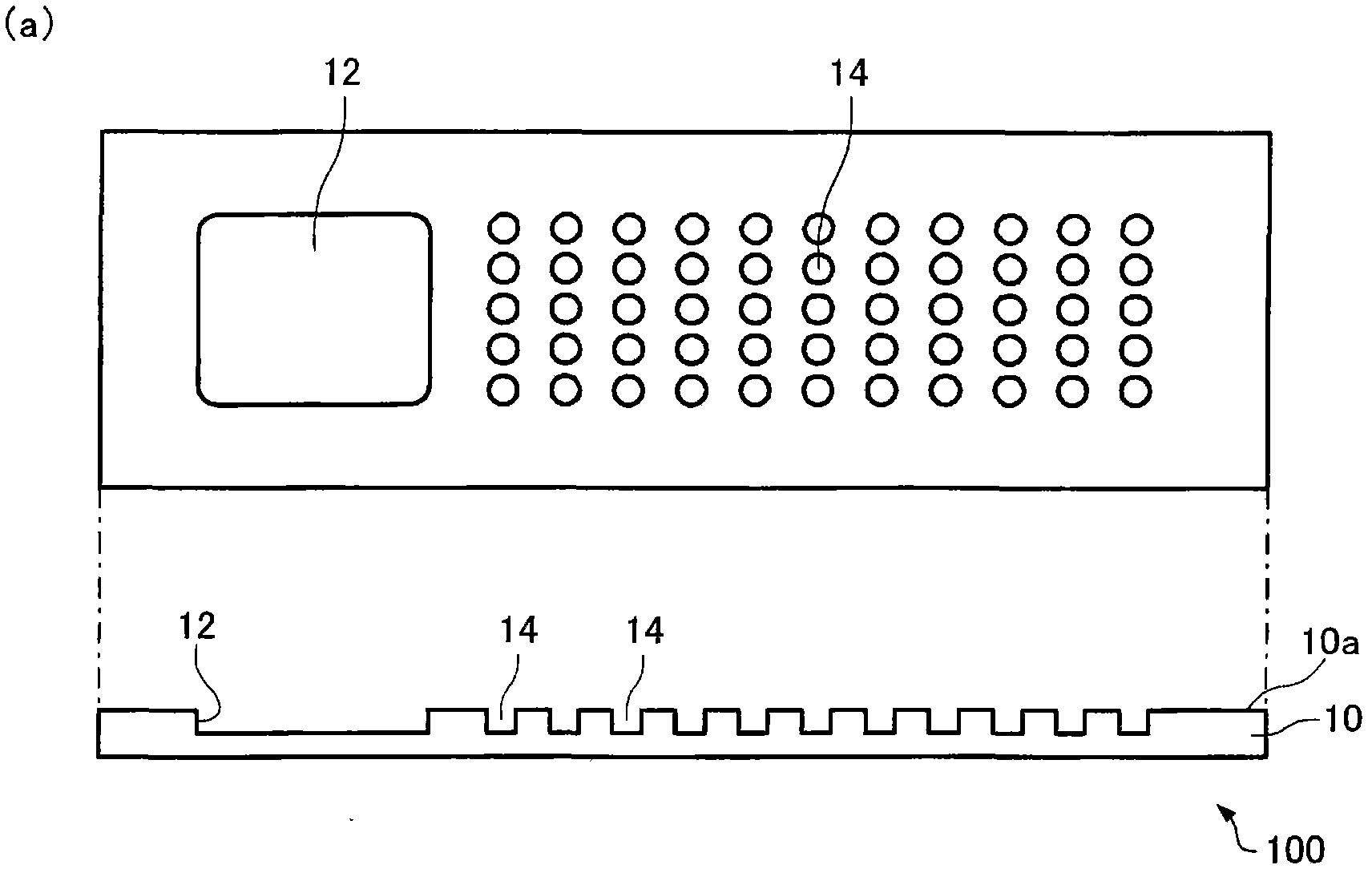

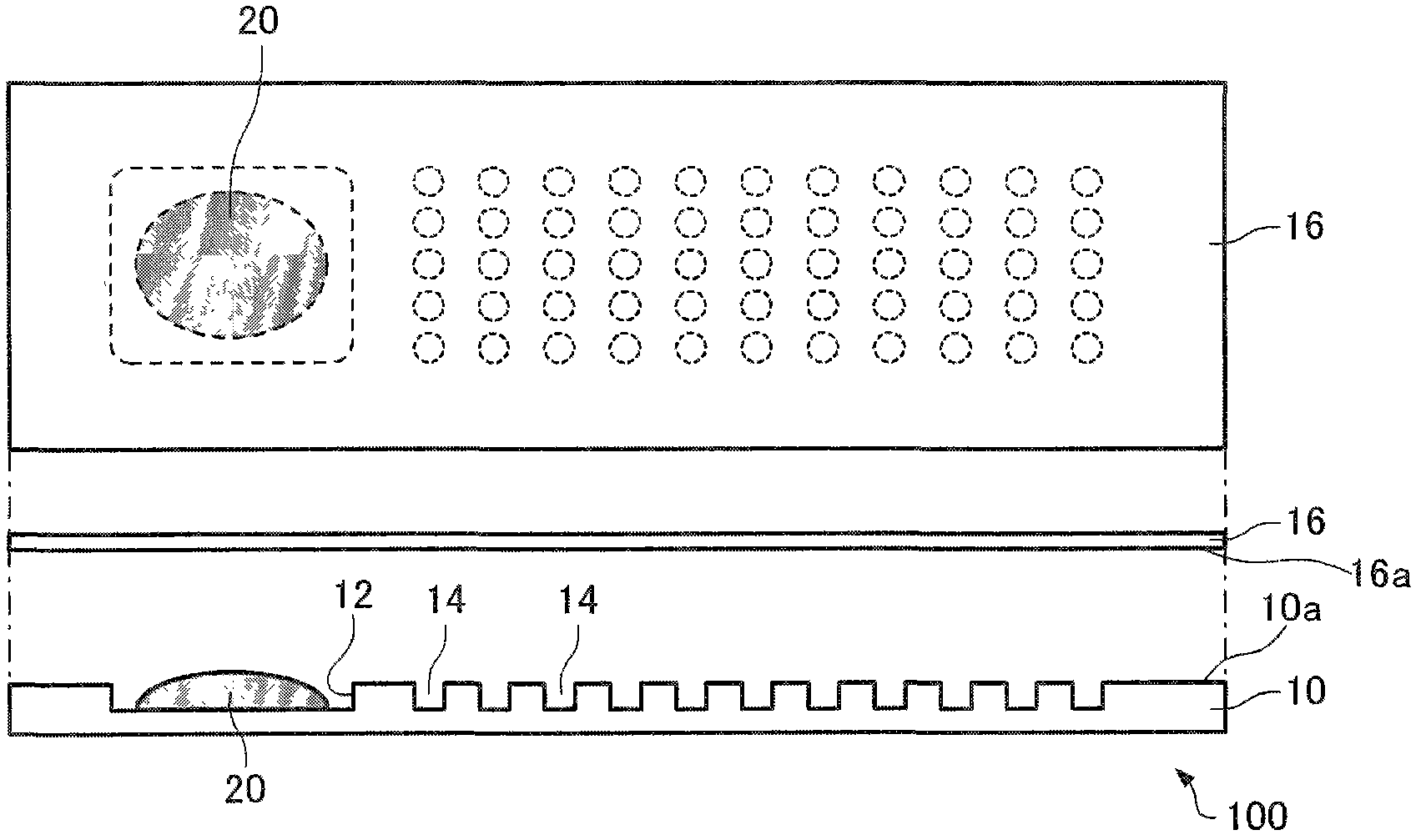

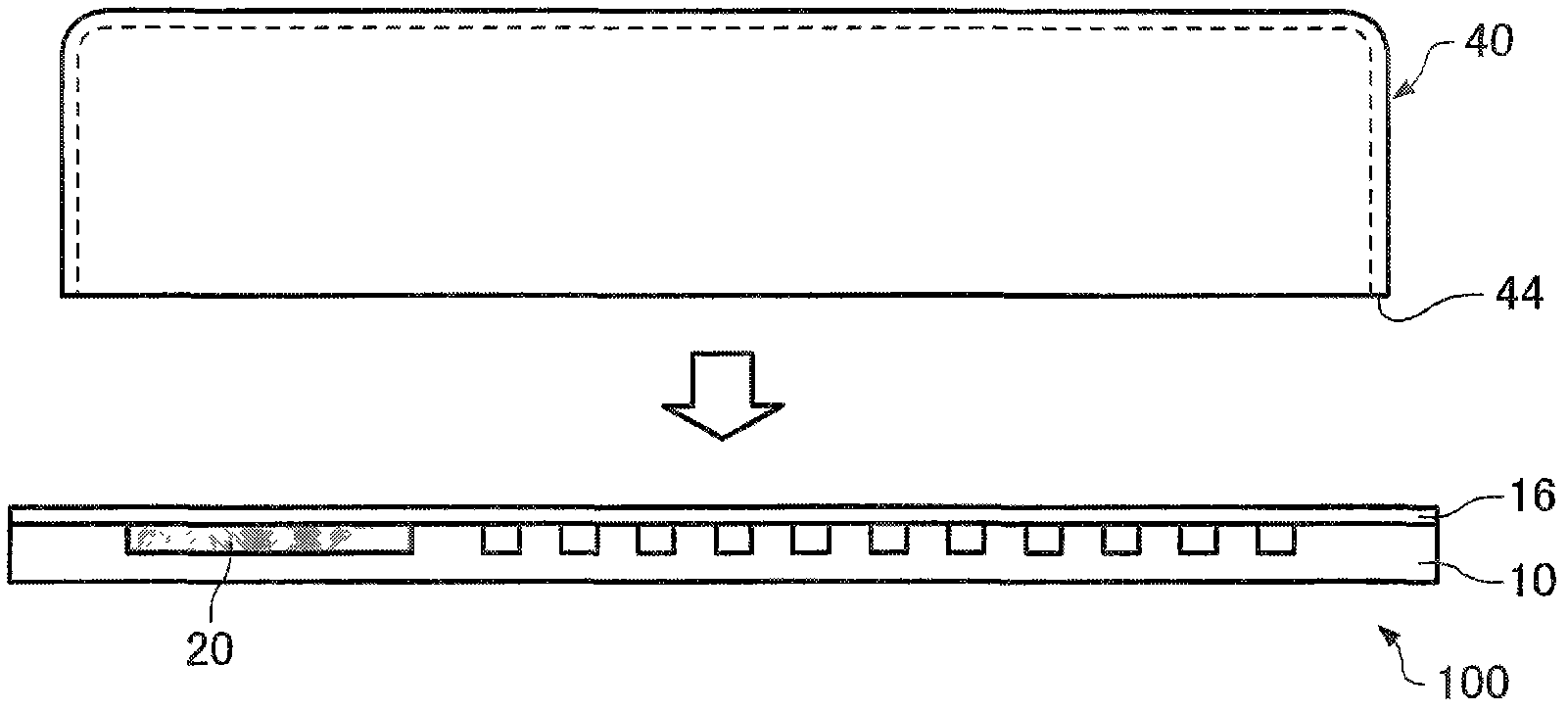

[0083] Figure 10 , Figure 11 and Figure 13 It is a figure explaining one process of the test method of the test liquid concerning the 2nd Embodiment of this invention ( Figure 10 , Figure 11 and Figure 13 The upper figure is a top view, and the lower figure is a cross-sectional view corresponding to the upper figure). Figure 12 It is for welding with ultrasonic welding device 300 Figure 10 A diagram illustrating the steps of the biochip 200 and the covering member 26 shown, Figure 14 It is to use the ultrasonic welding device 300 to adhere (weld) Figure 11 The figure for explaining the process of the shown biochip 200 and the covering member 26 .

[0084] In the test method of the liquid to be tested according to the present embodiment, using Figure 10 The biochip 200 is shown. The biochip 200 differs from the biochip 100 of the first embodiment in that the end portions 24 a of the plurality of second holes 24 are respectively formed of protrusions 11 . Th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com