Method for recovering blowing gas

A technology of blowing air and air, which is applied in the field of coal gasification to achieve obvious effects, large heat exchange capacity, and obvious effects of energy saving and consumption reduction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

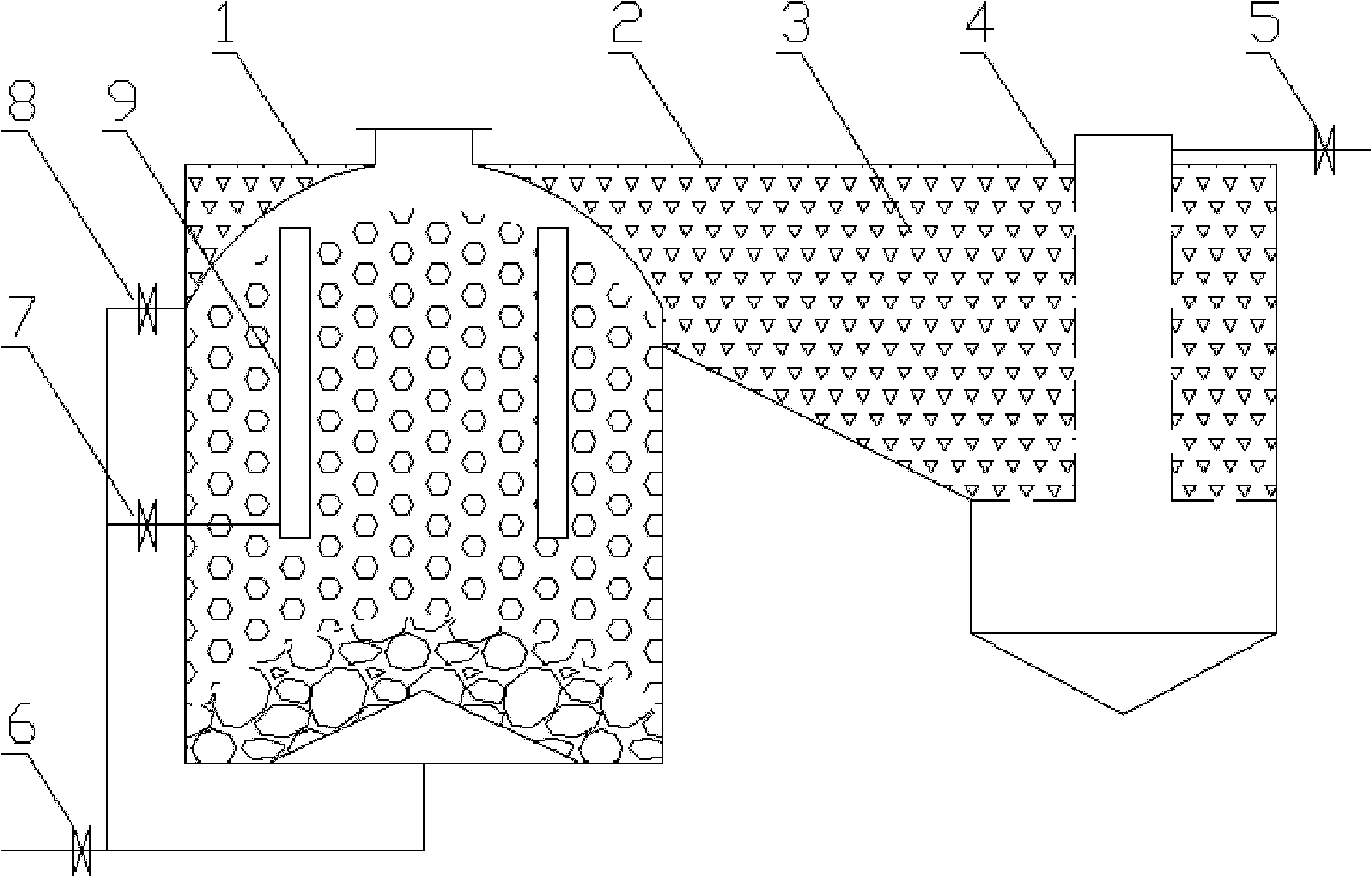

[0016] The present invention will be further described below in conjunction with accompanying drawing embodiment:

[0017] Such as figure 1 As shown, the present invention includes a blowing stage, an upper blowing stage and a lower blowing stage, and the three stages are carried out in a cycle. In the blowing stage, the air is divided into three paths through the blowing pipe and passed into the gas generator 1, wherein the first path is directly from the bottom of the furnace. Entering the gasifier 1, the second path provides air for the combustion of the blown air in the pipeline of the combustion cylinder 9 in the gasifier 1, and the third path provides air again for the combustion of the blown air on the surface of the charcoal layer in the gasifier 1 ; Part of the heat generated by combustion is stored inside the regenerative filler, and the other part is used for dry distillation of the coal on the surface of the charcoal layer of the gas generator.

[0018] The gas ge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com