As-cast finish concrete simulated coating

A technology for imitating fair-faced concrete and coatings, applied in the field of architectural decoration, can solve the problems of fading alkali, rust spots, and difficulty in meeting the high standard requirements of fair-faced concrete, and achieve the effect of breaking through technical bottlenecks and reducing construction costs.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

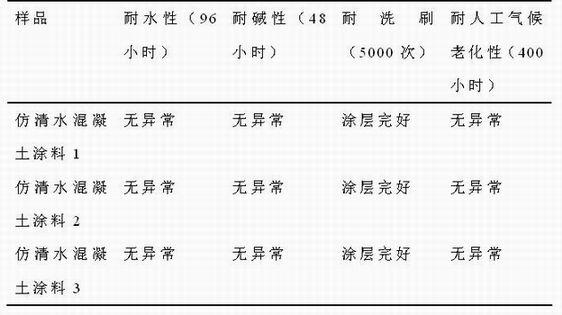

Examples

Embodiment 1

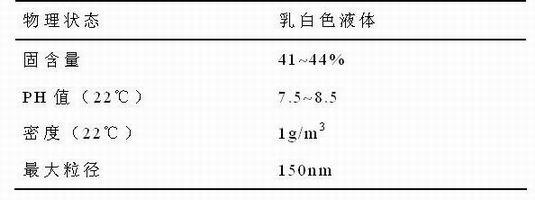

[0030] A kind of imitation fair-faced concrete paint, its formula is (percentage by weight):

[0031] Table 3 Imitation Fair-faced Concrete Coating A Formula

[0032]

[0033] Add water to the reaction kettle, add Wacker E22 or Protectosil SC 60 under stirring, and keep stirring for 20-50 minutes after the dispersion is uniform, to obtain the primer or top coat in composition A.

[0034] Add deionized water to the reaction kettle, and add sodium hexametaphosphate, 2-3168, and Texanol in turn under stirring. When one component is dispersed or dissolved evenly, the next component can be added. When all components are evenly dispersed , kept stirring for 5 minutes at a speed of 600~700rpm. After completion, add cement and R706 in sequence under stirring. When one component is evenly dispersed, the next component can be added. When all components are evenly dispersed, keep stirring at a speed of 1000~1500rpm for 20~30 minutes. After the completion, adjust the rotation speed t...

Embodiment 2

[0036] A kind of imitation fair-faced concrete paint, its formula is (percentage by weight):

[0037] Table 4 Imitation Fair-faced Concrete Coating B Formula

[0038]

[0039] Add water to the reaction kettle, add Wacker E22 or Protectosil SC 60 under stirring, and keep stirring for 20-50 minutes after the dispersion is uniform, to obtain the primer or top coat in composition B.

[0040] Add deionized water to the reaction kettle, add sodium hexametaphosphate, propylene glycol, 2-3168, Texanol in turn under stirring, when one component is dispersed or dissolved evenly, the next component can be added, when all components are dispersed After uniformity, keep stirring at a speed of 600~700rpm for 5 minutes. After completion, add heavy calcium carbonate, barium sulfate, and R706 in sequence under stirring. When one component is uniformly dispersed, the next component can be added. When all components are uniformly dispersed, keep stirring at a speed of 1000~1500rpm for 20 ~3...

Embodiment 3

[0042] A kind of imitation fair-faced concrete paint, its formula is (percentage by weight):

[0043] Table 5 Imitation Fair-faced Concrete Coating C Formula

[0044]

[0045] Add water to the reaction kettle, add Wacker E22 or Protectosil SC 60 under stirring, and keep stirring for 20-50 minutes after the dispersion is uniform, to obtain the primer or top coat in composition C.

[0046] Add deionized water to the reaction kettle, add sodium polyphosphate, 2-3168, Texanol, FSJ, AMP-95 in sequence under stirring, when one component is dispersed or dissolved evenly, the next component can be added, when After all components are evenly dispersed, keep stirring at a speed of 600~700rpm for 5 minutes. After completion, add quartz powder, kaolin, and R706 in sequence under stirring. When one component is evenly dispersed, the next component can be added. When all components are evenly dispersed, keep stirring at a speed of 1000~1500rpm for 20~30 minutes . After the completion,...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com