Hydroxy acrylic resin for ultra-fast dry automobile varnish and preparation method thereof

A hydroxyacrylic acid, ultra-fast drying technology, applied in coatings and other directions, can solve the problems of high price of varnishes, difficult to popularize and use in a large range, varnishes cannot have drying speed at the same time, etc., to achieve excellent leveling, cost-effective, paint The appearance of the film is smooth and bright

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

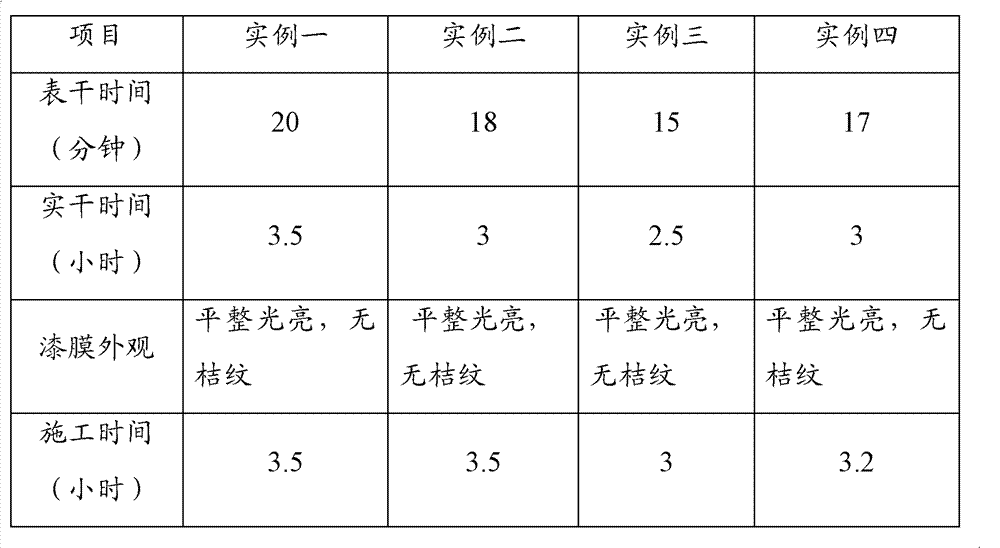

Examples

Embodiment 1

[0031] 1. Prepare raw materials:

[0032] Get 28 kilograms of trimethylbenzenes and 10 kilograms of xylenes, mix and form A material;

[0033] Get 20 kilograms of styrene, 12 kilograms of sec-butyl methacrylate, 10 kilograms of hydroxypropyl methacrylate, 2 kilograms of methacrylic acid and 0.4 kilogram of maleic anhydride, and mix them into B material;

[0034] Get 1 kilogram of benzoyl peroxide, 2 kilograms of dicumyl peroxide and 3 kilograms of di-tert-butyl peroxide and mix to form C material;

[0035] 2. Put material A into the reactor and raise the temperature to 152°C;

[0036] 3. Add material B dropwise, the dropping time is controlled at 3.5 hours, and the temperature in the reactor is controlled at 152°C;

[0037] 4. After the dropwise addition, keep warm at 152°C for 4 hours;

[0038] 5. Add material C and keep warm for another 4 hours;

[0039] 6. Lower the temperature below 80° C., filter and pack to obtain the ultra-fast-drying hydroxyacrylic resin for automo...

Embodiment 2

[0041] 1. Prepare raw materials:

[0042] Get 29 kilograms of trimethylbenzenes and 12 kilograms of xylenes, mix and form A material;

[0043] Get 22 kilograms of α-styrene, 13 kilograms of tert-butyl methacrylate, 11 kilograms of hydroxypropyl methacrylate, 3 kilograms of methacrylic acid and 0.4 kilogram of maleic anhydride, and mix them into material B;

[0044] Get 2 kilograms of benzoyl peroxide, 3 kilograms of dicumyl peroxide and 2 kilograms of di-tert-butyl peroxide and mix to form C material;

[0045] 2. Put material A into the reactor and heat up at 148°C;

[0046] 3. Add material B dropwise, the dropping time is controlled within 4 hours, and the temperature in the reactor is controlled at 148°C;

[0047] 4. After the dropwise addition, keep warm at 148°C for 4 hours;

[0048] 5. Add material C and keep warm for another 4 hours;

[0049] 6. Lower the temperature below 80° C., filter and pack to obtain the ultra-fast-drying hydroxyacrylic resin for automobile var...

Embodiment 3

[0051] 1. Raw material preparation:

[0052] Get 30 kilograms of mesitylene and 15 kilograms of dimethylbenzene, mix and form A material;

[0053] Get 22 kilograms of styrene, 12 kilograms of tert-butyl methacrylate, 12 kilograms of hydroxypropyl methacrylate, 4 kilograms of methacrylic acid and 0.5 kilogram of fumaric acid, and mix them into B material;

[0054] Get 2 kilograms of benzoyl peroxide, 1 kilogram of dicumyl peroxide and 3 kilograms of di-tert-butyl peroxide and mix to form C material;

[0055] 2. Put material A into the reactor and heat up at 150°C;

[0056] 3. Add material B dropwise, the dropping time is 3 hours, and the temperature in the reactor is controlled at 150°C;

[0057] 4. After the dropwise addition, keep warm at 150°C for 4 hours;

[0058] 5. Add material C and keep warm for another 4 hours;

[0059] 6. Lower the temperature below 80° C., filter and pack to obtain the ultra-fast-drying hydroxyacrylic resin for automobile varnishes of the present...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com