Method for preparing rubber peptizer DBD

A technology of rubber peptizer and oxidant, which is applied in the preparation of hydrogenated polysulfide/polysulfide, organic chemistry, etc., can solve the problems of high material cost and power cost, direct treatment without separation, and difficult control of the production process. Achieve the effects of reducing the cost of three wastes treatment, facilitating popularization and application, and easy control

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

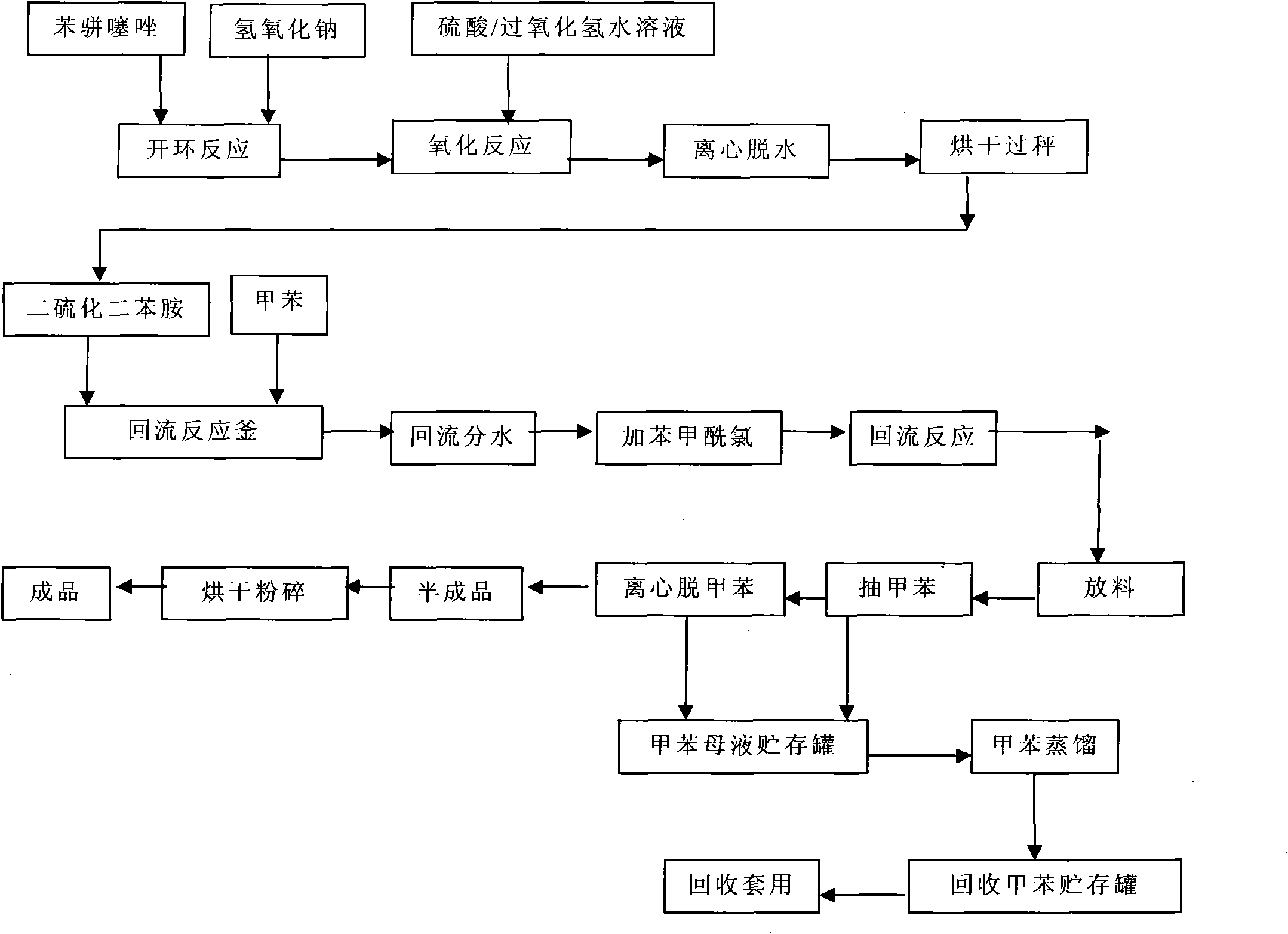

Image

Examples

Embodiment 1

[0037] The preparation method of rubber peptizer DBD adopts the following steps:

[0038] (1) Put 500 kg of water and 110 kg of sodium hydroxide in turn into a reaction kettle equipped with a thermometer and agitator, stir to dissolve, then add 200 kg of benzothiazole, heat up to 80°C, and react for 3 hours to normal temperature spare;

[0039] (2) 200 kilograms of water, 70 kilograms of sulfuric acid with a concentration of 98% and 90 kilograms of aqueous hydrogen peroxide with a concentration of 40% are prepared as an oxidant, and pumped to a metering tank for standby; the prepared oxidant is dripped into the step (1) In the reaction solution, the pH value is controlled to 6-7 at the end point, and the temperature is reduced to suction filtration at the end point, and washed to obtain diphenylamine disulfide;

[0040] (3) Put 606 kg of toluene and 300 kg of diphenylamine disulfide in turn into the reaction kettle equipped with a thermometer and agitator, start stirring, hea...

Embodiment 2

[0042] The preparation method of rubber peptizer DBD adopts the following steps:

[0043] (1) Put 600 kg of water and 150 kg of sodium hydroxide in turn into a reaction kettle equipped with a thermometer and agitator, stir to dissolve, then add 250 kg of benzothiazole, heat up to 75°C, and react for 3.5 hours to normal temperature spare;

[0044] (2) 250 kilograms of water, 95 kilograms of sulfuric acid with a concentration of 95% and 130 kilograms of aqueous hydrogen peroxide with a concentration of 50% are prepared as an oxidant, and pumped to a metering tank for standby; the prepared oxidant is dripped into the step (1) In the reaction solution, the pH value is controlled to 6-7 at the end point, and the temperature is reduced to suction filtration at the end point, and washed to obtain diphenylamine disulfide;

[0045] (3) Put 693 kg of toluene and 350 kg of diphenylamine disulfide in sequence into the reaction kettle equipped with a thermometer and agitator, start stirri...

Embodiment 3

[0047] The preparation method of rubber peptizer DBD adopts the following steps:

[0048] (1) Put 400 kg of water and 90 kg of sodium hydroxide in turn into a reaction kettle equipped with a thermometer and agitator, stir to dissolve, then add 150 kg of benzothiazole, heat up to 70°C, and react for 2.5 hours to normal temperature spare;

[0049](2) 150 kilograms of water, 60 kilograms of sulfuric acid with a concentration of 93% and 80 kilograms of aqueous hydrogen peroxide with a concentration of 27.5% are prepared as an oxidant, and pumped to a metering tank for standby; the prepared oxidant is dripped into the step (1) In the reaction solution, the pH value is controlled to 6-7 at the end point, the temperature is lowered and the suction is filtered at the end point, and diphenylamine disulfide is obtained by washing;

[0050] (3) Put 433 kg of toluene and 250 kg of diphenylamine disulfide into the reaction kettle equipped with a thermometer and agitator in sequence, start...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com