Electrodeionization (EDI) method and system dispensing with ion exchange membranes

A technology of ion exchange membrane and electrodeionization, which is applied in ion exchange, ion exchange regeneration, ion exchange water/sewage treatment, etc., can solve the problems of membrane pollution, inconvenient installation and maintenance, complex device structure, etc., and overcome membrane fouling Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

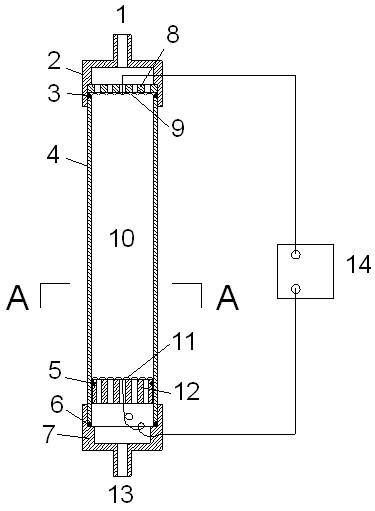

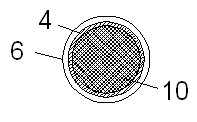

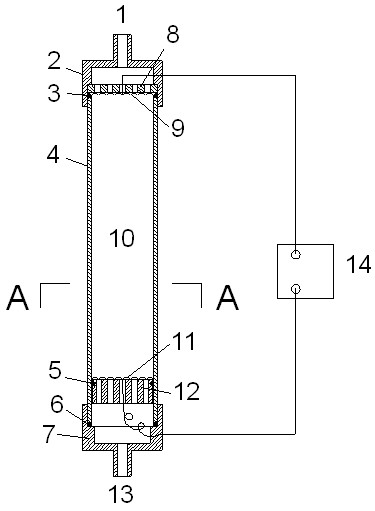

[0028] The secondary reverse osmosis effluent of the seawater desalination system with a conductivity of about 10μs / cm adopts figure 1 The membraneless electrodeionization system shown was used for the treatment. The system adopts strong acidic cation resin and strong basic anion resin, the two are evenly mixed, the volume ratio of cation and anion resin is 1:2, and the height of resin layer is 0.16m. The operating conditions are as follows: regenerative current density 280A / m 2 ; Average voltage 340V; regeneration water velocity 15 m / h; regeneration lasted 3.6h; treatment flow velocity 15m / h. The operation results are as follows: the regeneration rate is 90%; the average conductivity of the concentrate produced during the regeneration process is about 290μs / cm; the conductivity of the effluent after treatment is 0.060-0.070 μs / cm; the water recovery rate is 97%; the energy consumption is 0.22 kWh / m 3 water.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com