Cover plate of automobile trunk cover and manufacturing process thereof

A technology for manufacturing crafts and storage boxes, which is applied to vehicle parts, transportation and packaging, etc., which can solve the problems of high cost, complicated process, and easy occurrence of defective products, and achieve enhanced load-bearing capacity, high product qualification rate, and good load-bearing effect Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

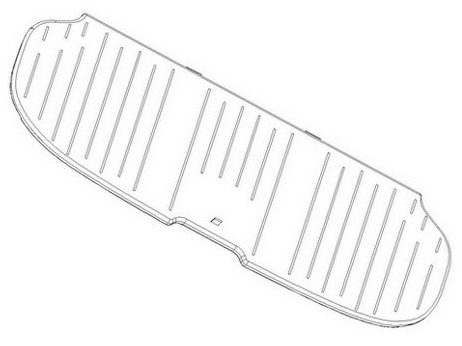

[0027] figure 1 — Figure 6 Shown is a cover plate for the rear storage box of a car. The main body is similar to an oblong structure. Its main body is an HDPE blow-molded main body 7, and a PET needle-punched non-woven fabric 1 fabric layer is bonded to the outside. Rope hook and drawstring 2.

[0028] The blow molding body 7 is a hollow structure with closed surroundings, and reinforcing ribs are evenly distributed in the hollow cavity.

[0029] Steel pipes 5 are arranged at intervals in the hollow cavity of the body.

[0030] The production process of the above-mentioned automobile rear storage box cover cover is blow-molded using a special mold, and it is carried out in the following steps: mold opening → hanging PET needle-punched non-woven fabric on the fixed mold → inserting 180- Molten HDPE at 220℃ is blown into a pocket shape → the mold is closed and the product is kept under pressure at the same time, and inflated → the ejector pin of the movable mold is pushed to...

PUM

| Property | Measurement | Unit |

|---|---|---|

| melting point | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com