Diamond grinding tool of ceramic-metallic bond and preparation method of grinding tool

A technology of metal bond and ceramic bond, applied in metal processing equipment, grinding/polishing equipment, abrasives, etc., can solve the problems of high brittleness, long production cycle, poor wettability of diamond, etc., to improve strength and hardness, Improves toughness and strength, and is easy to shape and sharpen

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

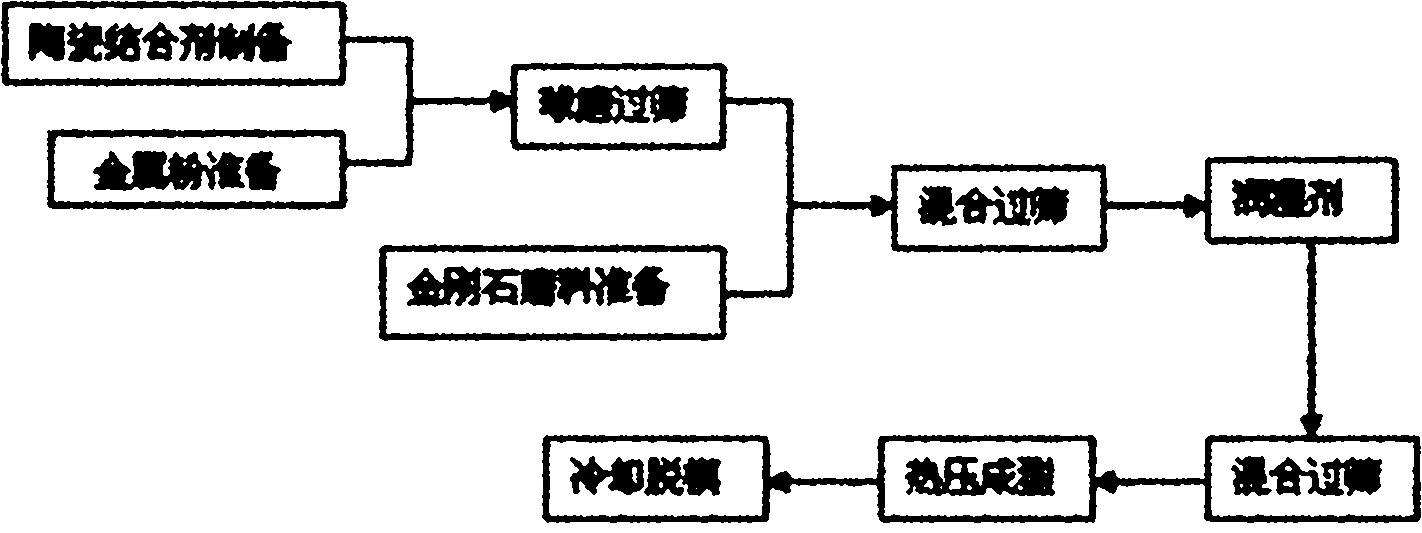

[0030] The specific process of this example is as follows image 3 shown.

[0031] Table 1: Ceramic-metal bond components and proportions

[0032] components

SiO 2

Al 2 o 3

B 2 o 3

Li 2 o

Na 2 o

K 2 o

ZnO

Ti

Al

wt%

44

9

19

6

7

3

5

5

2

[0033] Analytical pure SiO 2 、Al 2 o 3 、HBO 3 , Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 and ZnO as raw materials, calculated according to the formula in the above table, weighed, mixed evenly, put into a crucible, heated to 1300 ° C in a high-temperature frit furnace, kept for 2 hours, water quenched after the raw materials were completely melted, and then wet milled on a ball mill ( 1000r / min) for 24h, dry the wet-milled slurry in an oven at 100°C for 12h, dry-grind for 4h, and pass through a 200-mesh sieve to make a basic vitrified bond.

[0034] Add Ti powder (particle size ≤ 20 μm) and Al powder (particle size ≤ 20 μm)...

Embodiment 2

[0038] Table 2: Ceramic-metal bond components and proportions

[0039] components

SiO 2

al 2 o 3

B 2 o 3

Li 2 o

Na 2 o

K 2 o

ZnO

Ti

Al

wt%

48

12

12

3

8

4

2

8

3

[0040] Analytical pure SiO 2 、Al 2 o 3 、HBO 3 , Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 and ZnO as raw materials, calculated according to the above formula, weighed, mixed evenly, put into a crucible, heated to 1300 °C in a high-temperature frit furnace, kept for 2 hours, water quenched after the raw materials were completely melted, and then wet milled on a ball mill (1000r / min) for 24 hours, dry the wet-milled slurry in an oven at 100°C for 12 hours, then dry-mill it for 4 hours and pass it through a 200-mesh screen to make a basic vitrified bond.

[0041]Add Ti powder (particle size ≤ 20 μm) and Al powder (particle size ≤ 20 μm) designed in the formula to the basic vitrified bond, and mix them ...

Embodiment 3

[0046] Table 3: Ceramic-metal bond components and proportions

[0047] components

SiO 2

al 2 o 3

B 2 o 3

Li 2 o

Na 2 o

K 2 o

ZnO

Ti

Al

wt%

41

8

18

6

9

6

3

6

3

[0048] Analytical pure SiO 2 、Al 2 o 3 、HBO 3 , Li 2 CO 3 、Na 2 CO 3 、K 2 CO 3 and ZnO as raw materials, calculated according to the above formula, weighed, mixed evenly, put into a crucible, heated to 1300 °C in a high-temperature frit furnace, kept for 2 hours, water quenched after the raw materials were completely melted, and then wet milled on a ball mill (1000r / min) for 24 hours, dry the wet-milled slurry in an oven at 100°C for 12 hours, then dry-mill it for 4 hours and pass it through a 200-mesh screen to make a basic vitrified bond.

[0049] Add Ti powder (particle size ≤ 20 μm) and Al powder (particle size ≤ 20 μm) designed in the formula to the basic vitrified bond, and mix them ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Granularity | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com