High-performance environmentally-friendly copper-bismuth dual-metal bearing material and manufacturing method thereof

A bearing material, high-performance technology, applied in the direction of metal layered products, chemical instruments and methods, layered products, etc., can solve problems such as lack of

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

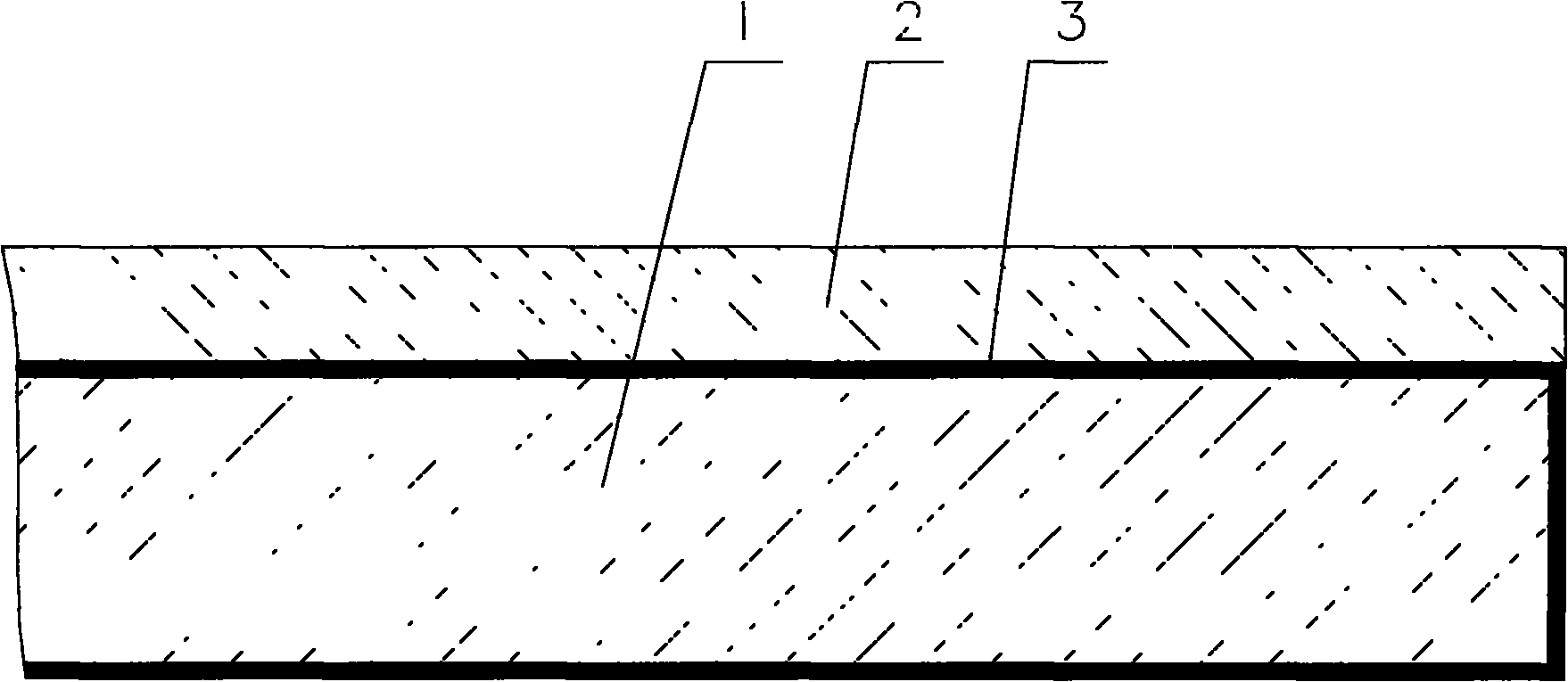

[0024] High-performance environment-friendly copper-bismuth bimetallic bearing material: it is sintered by steel plate 1 and copper-based alloy wear-resistant layer 2; the formula composition of copper-based alloy wear-resistant layer is: bismuth 1%, tin 5%, and The amount is copper. There is a copper plating layer 3 on the surface of the steel plate.

[0025] The manufacturing method of the above-mentioned high-performance environment-friendly copper-bismuth bimetallic bearing material is: steel plate shearing and blanking → steel plate copper-plated to form a copper layer 3 → inspection → powder spreading → primary sintering → rolling → secondary sintering → re-rolling → high performance The finished products of environmental protection copper bismuth bimetallic bearing material are as follows: figure 1 shown, where:

[0026] Spreading powder: 1% bismuth powder, 5% tin powder and copper powder as the balance are accurately weighed and proportioned by weight, and fully mixe...

Embodiment 2

[0030] High-performance environment-friendly copper-bismuth bimetallic bearing material: it is sintered by steel plate 1 and copper-based alloy wear-resistant layer 2; the formula composition of copper-based alloy wear-resistant layer is as follows: bismuth 2%, tin 8%, balance The amount is copper. There is a copper plating layer 3 on the surface of the steel plate.

[0031] The manufacturing method of the above-mentioned high-performance environment-friendly copper-bismuth bimetallic bearing material is: steel plate shearing and blanking → steel plate copper-plated to form a copper layer 3 → inspection → powder spreading → primary sintering → rolling → secondary sintering → re-rolling → high performance The plate finished product of environmental protection copper bismuth bimetallic bearing material, in which:

[0032] Powder coating: first melt bismuth, tin and copper together to make alloy powder, wherein the composition of alloy powder is 2% bismuth, 8% tin and the balanc...

Embodiment 3

[0036] High-performance environment-friendly copper-bismuth bimetallic bearing material: it is sintered by steel plate 1 and copper-based alloy wear-resistant layer 2; the formula composition of copper-based alloy wear-resistant layer is as follows: bismuth 3%, tin 10%, balance The amount is copper.

[0037] The manufacturing method of the above-mentioned high-performance environment-friendly copper-bismuth bimetallic bearing material is: steel plate shearing and blanking→inspection→powder spreading→primary sintering→rolling→secondary sintering→re-rolling→plate of high-performance environment-friendly copper-bismuth bimetallic bearing material finished product, of which,

[0038] Spreading powder: 3% of bismuth powder, 10% of tin powder and the balance of copper powder are accurately weighed and proportioned according to the weight percentage, and fully mixed into a mixed powder, and then the evenly mixed mixed powder is spread on a clean cold-rolled On the low carbon steel p...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com