Jet manipulator

A spray manipulator and engine technology, which is applied in the shaft lining, tunnel lining, underground chamber, etc., can solve the problems such as the adaptability and efficiency of the spray manipulator, the inability to carry out the concrete spraying work, and the removal of obstacles encountered in the construction tunnel, etc., to achieve Choose the effect of convenient and quick operation, reduce safety hazards, and reduce friction

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

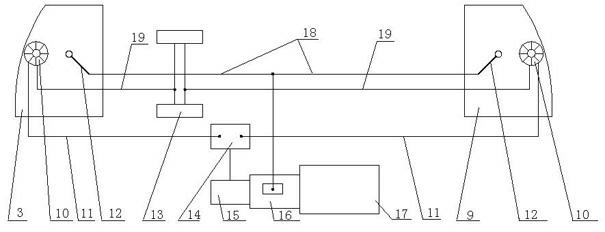

[0018] See Figure 1 to Figure 4 The spray manipulator includes a car body 1, a traveling wheel 2 and a boom 4 arranged on the car body 1, a driving control system connected to the traveling wheel 1, a boom hydraulic system for controlling the work of the boom 4, and a boom slewing platform to support walking Structure: driving control system comprises engine 17, the walking pump 16 that is connected with engine 17 and the steering axle 13 of steering pump 15, walking wheel, front cab 9 and rear cab 3 are respectively set at the front and back of car body 1, each cab 3. The steering gear 10 and the flexible shaft joystick 12 are separately arranged in 9; the flexible shaft joysticks 12 are respectively connected to the walking pump 16 through the flexible shaft 18, and the walking pump 16 is connected to the drive shaft of the road wheel 2; each steering gear The oil inlet pipe 11 of 10 links to each other with the steering pump 15 through the switching valve 14, and the oil o...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com