Steam and nitrogen composite swallowing-spitting oil extraction method

A steam and nitrogen technology, which is used in the production of fluids, earthmoving, wellbore/well components, etc., to reduce production costs and crude oil viscosity, large drainage area, and increase driving energy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

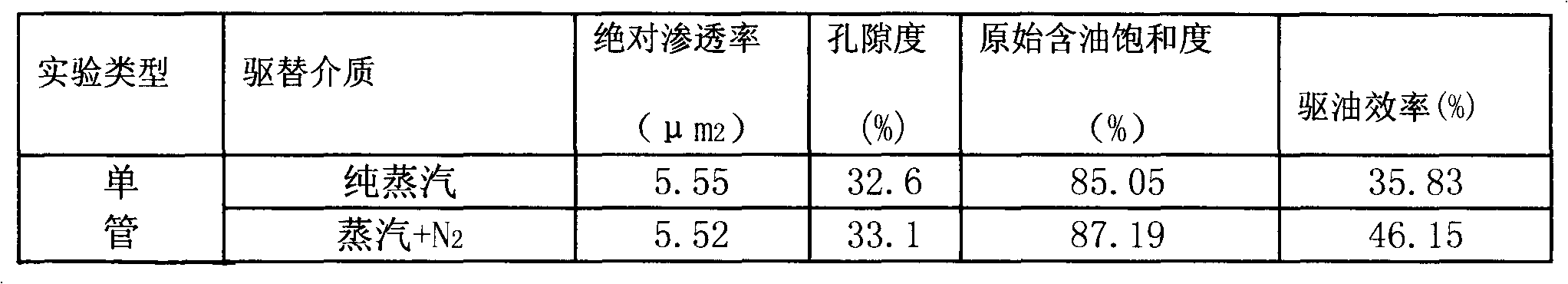

Examples

Embodiment 1

[0025] The method proceeds as follows:

[0026] a. Downstream steam injection pipe string: the pipe string structure is from bottom to top, the uniform steam distribution pipe string with uniform steam distribution valve and compensator, the upper part is connected to the injection and production integrated pump, and the outer diameter of the pump is Φ88.9mm tubing, The wellhead is installed with subcritical steam injection wellhead.

[0027] b. Note N 2 And steam: inject 25000Nm into the oil well 3 Nitrogen and 2,500 tons of steam, the steam is injected from the oil pipe, and the nitrogen is injected from the oil jacket annulus. During the steam injection process, pay attention to record the change of the steam injection pressure, so as to adjust the steam injection parameters and the injection speed of nitrogen according to the pressure in time, so that the steam injection is uniform throughout the process. Nitrogen injection;

[0028] c. Stewing well: After injecting ste...

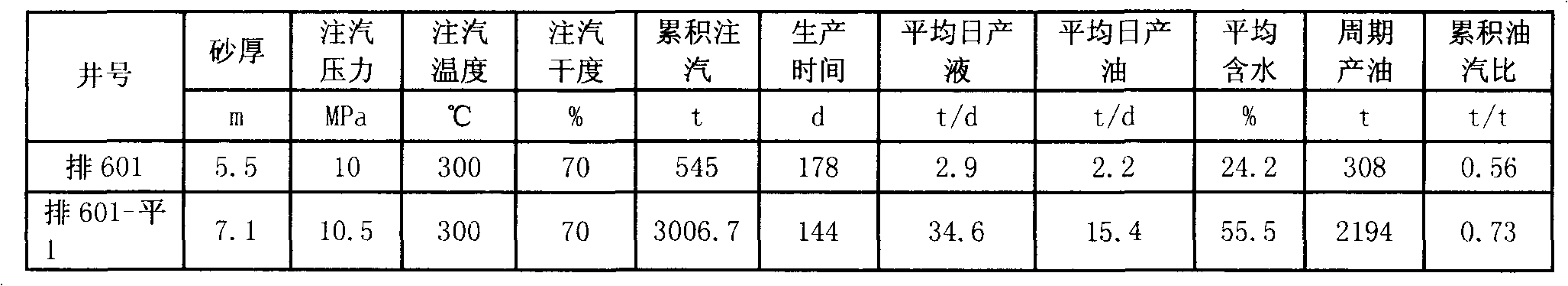

Embodiment 2

[0033] The method proceeds as follows:

[0034] a. Downstream steam injection pipe string: the pipe string structure is from bottom to top, the uniform steam distribution pipe string with uniform steam distribution valve and compensator, the upper part is connected to the injection and production integrated pump, and the outer diameter of the pump is Φ88.9mm tubing, The wellhead is installed with subcritical steam injection wellhead.

[0035] b. Note N 2 And steam: inject 55000Nm into the oil well 3 Nitrogen and 1,500 tons of steam, the steam is injected from the oil pipe, and the nitrogen is injected from the oil jacket annulus. During the steam injection process, pay attention to record the change of the steam injection pressure, so as to adjust the steam injection parameters and the injection speed of nitrogen according to the pressure in time, so that the steam injection is uniform throughout the process. Nitrogen injection;

[0036] c. Stewing well: After injecting ste...

Embodiment 3

[0041] The method proceeds as follows:

[0042] a. Downstream steam injection pipe string: the pipe string structure is from bottom to top, the uniform steam distribution pipe string with uniform steam distribution valve and compensator, the upper part is connected to the injection and production integrated pump, and the outer diameter of the pump is Φ88.9mm tubing, The wellhead is installed with subcritical steam injection wellhead.

[0043] b. Note N 2 And steam: inject 40000Nm into the oil well 3 Nitrogen and 2,000 tons of steam, the steam is injected from the oil pipe, and the nitrogen is injected from the oil jacket annulus. During the steam injection process, pay attention to record the change of the steam injection pressure, so as to adjust the steam injection parameters and the injection speed of nitrogen according to the pressure in time, so that the steam injection is uniform throughout the process. Nitrogen injection;

[0044] c. Stewing well: After injecting ste...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com