Method for producing butadiene based on ionic liquid complex solvent

An ionic liquid and composite solvent technology, applied in the field of olefin production, can solve the problems of high energy consumption, low selectivity and equipment corrosion of butadiene, and achieve the effect of increasing the recovery section, reducing the loss of acetonitrile and reducing the loss

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

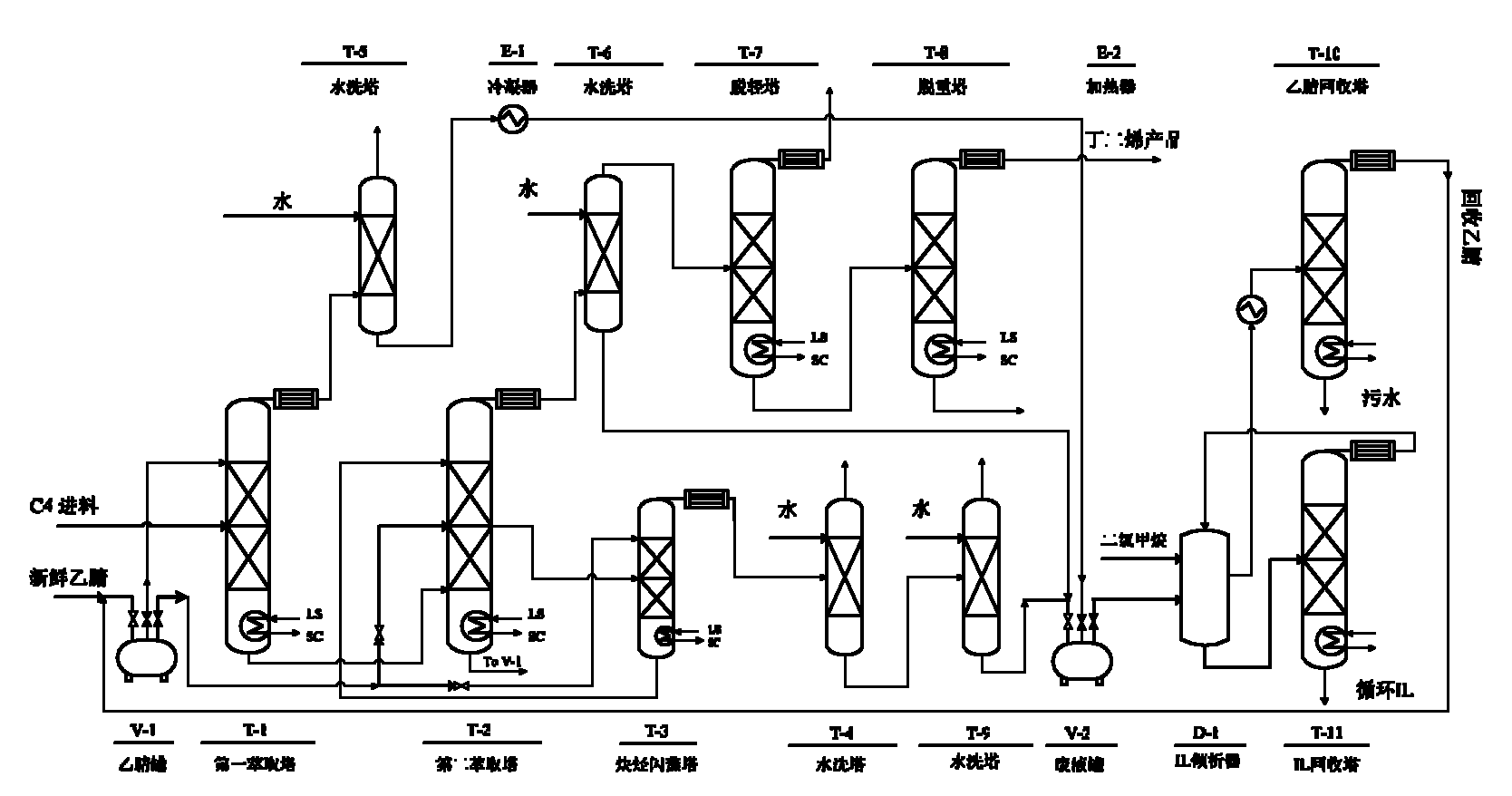

[0031] Adopt above-mentioned embodiment, mixing C4 flow rate is 15710kg / h (butadiene mass fraction is 53.46%), ionic liquid composite solvent ([emim][PF 6 ]: acetonitrile: water=7.5: 80: 12.5, mass ratio) is 128945kg / h. The results of this embodiment have been compared with the former acetonitrile process, and the results are listed in Tables 1 and 2, from which it can be seen that the ionic liquid process is superior to the former in terms of acetonitrile consumption, energy consumption, product purity or extraction kettle temperature. The existing acetonitrile method is better. Simultaneously in this embodiment, the distribution of ionic liquid in flow process is as follows figure 2 As shown, it can be seen that the recovery rate of ionic liquid can reach 99.9%, and the loss amount is 8.68×10 -2 kg / ton of butadiene.

[0032] Table 1 Comparison of key performance indicators of the two processes

[0033]

[0034]

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com