Turnover type upright column assembly, trailer and transportation method of long columnar goods

A cargo transportation and overturning technology, applied in the field of transportation equipment and its components, can solve the problems of damage to the trailer column and frame structure, increase the reliability of transporting long column-shaped goods, damage to the column frame structure, etc. The effect of unloading, ensuring transportation reliability, and strengthening support

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0016] Typical embodiments embodying the features and advantages of the present invention will be described in detail in the following description. It should be understood that the invention is capable of various changes in different embodiments without departing from the scope of the invention, and that the description and illustrations therein are illustrative in nature and not limiting. this invention.

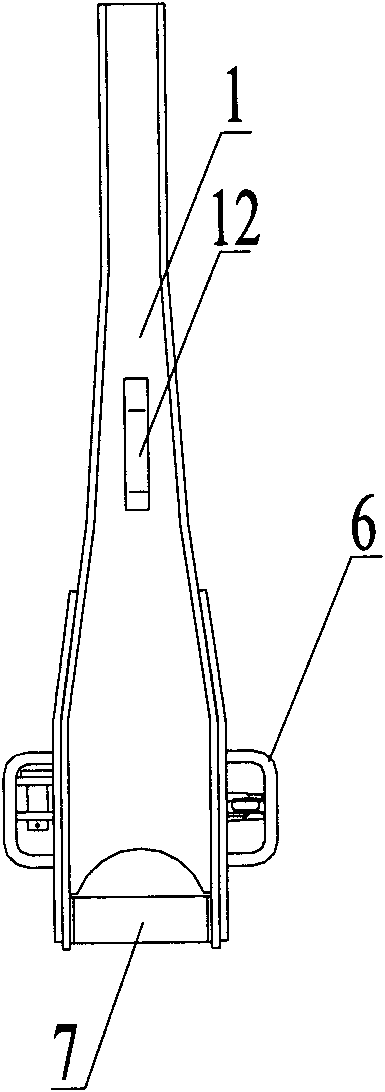

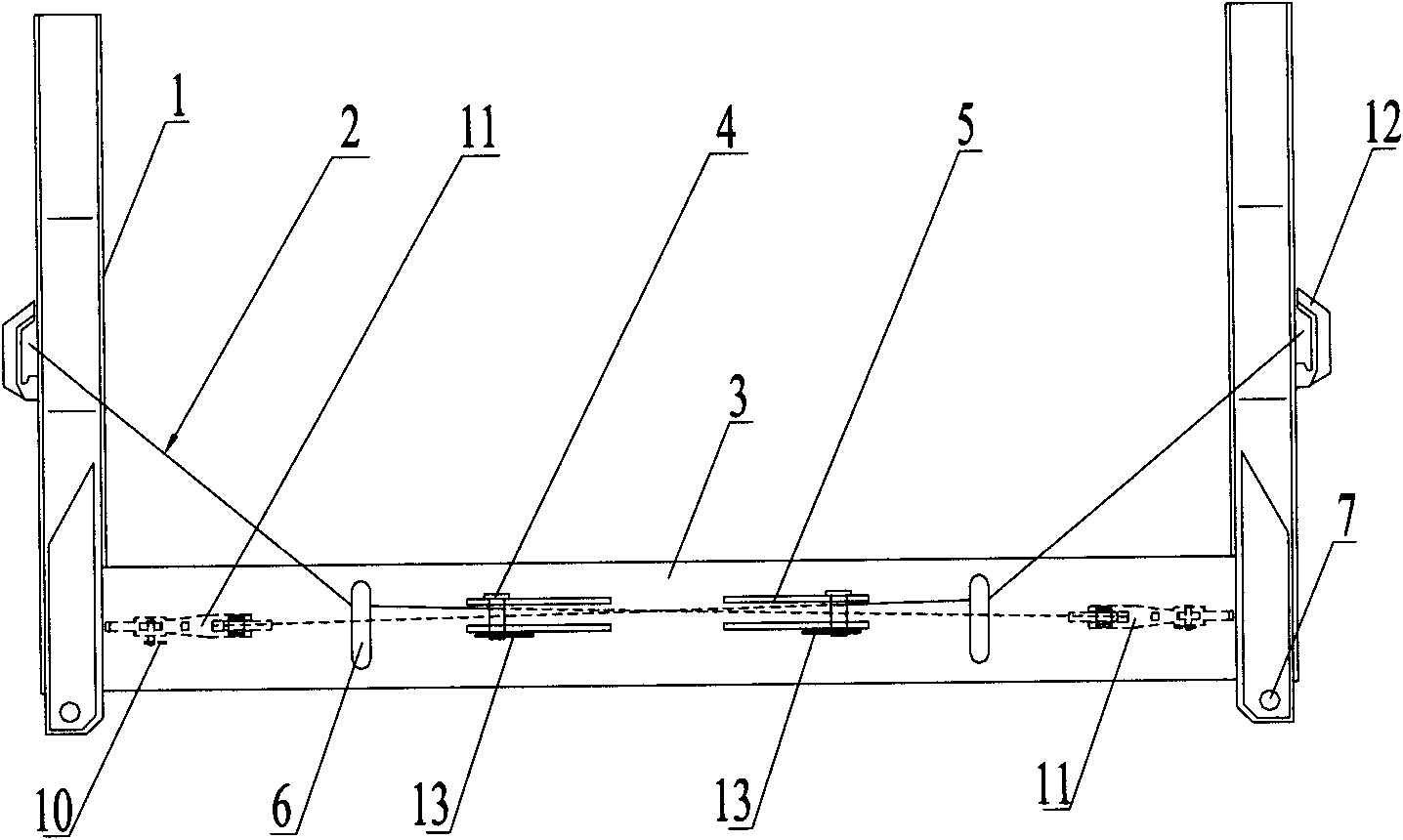

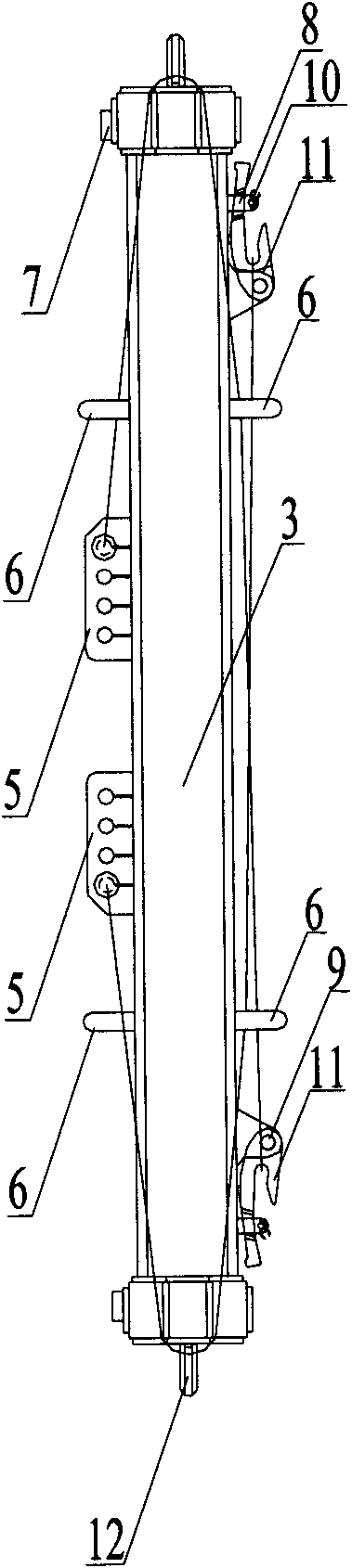

[0017] The trailer of the embodiment of the present invention has the reversible column assembly of the embodiment of the present invention. The trailer of the embodiment of the present invention can use the method for transporting long columnar goods in the embodiment of the present invention to transport long columnar goods. The implementation of the method for transporting column-shaped long goods in the embodiment of the present invention relies on the reversible column assembly in the embodiment of the present invention.

[0018] But the application of the overturnin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com