Preparation method of Ni-SiO2/Al2O3 catalyst

A catalyst, c·min-1 technology, applied in the preparation of organic compounds, chemical instruments and methods, preparation of hydroxyl compounds, etc., can solve the problems of increased consumption, unsatisfactory hydrogenation effect, etc., to reduce the content and reduce the color of the product. degree, the effect of improving the utilization rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

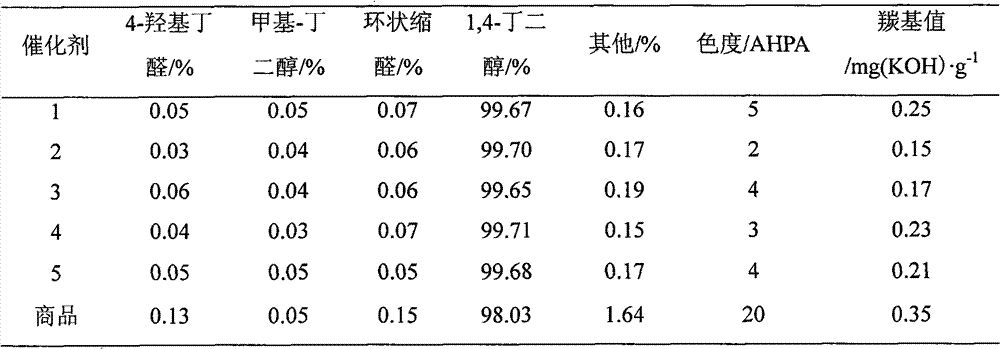

Embodiment 1

[0034] Take the specific surface area as 223m 2 g -1 , the pore volume is 0.62cm 3 g -1 , with an average pore diameter of 9.75nm on the alumina carrier, impregnating the ethanol solution of tetraethyl orthosilicate on the alumina carrier, drying, and calcining to obtain SiO with a silicon mass fraction of 0.5%. 2 / Al 2 o 3 Carrier: Weigh 50.0g nickel chloride and 25.3g urea to prepare 100ml nickel salt solution; take 90ml prepared nickel salt solution and impregnate it into 100g SiO with a silicon mass fraction of 0.5%. 2 / Al 2 o 3 In the carrier, stir well at room temperature, seal it in the container and let it stand for 14 hours; heat the sealed container with the sample in a blast oven at 90°C for 10 hours; then open the container, and dry the sample in a blast oven at 90°C Dry for 5 hours, then heat up to 120°C and dry for 4 hours; -1 Heating up to 110°C, and then at 0.5°C·min -1 Heating up to 250°C, and finally at 2°C·min -1 Raise the temperature to 450°C, kee...

Embodiment 2

[0036] Take the specific surface area as 110m 2 g -1 , the pore volume is 0.40cm 3 g -1 , with an average pore diameter of 14.08nm on the alumina support, impregnating the ethanol solution of methyl orthosilicate on the alumina support, drying, and roasting to obtain SiO with a silicon mass fraction of 1%. 2 / Al 2 o 3 Carrier: Weigh 124.4g of nickel sulfate and 14.2g of urea to prepare 100ml of nickel salt solution; take 90ml of prepared nickel salt solution and impregnate it into 100g of SiO with a silicon mass fraction of 1%. 2 / Al 2 o 3 In the carrier, stir well at room temperature, seal it in the container and let it stand for 20 hours; place the sealed container with the sample in a blast oven at 95°C and heat it for 10 hours; then open the container, and dry the sample in a blast oven at 95°C Dry for 5 hours, then heat up to 120°C and dry for 4 hours; -1 Heating up to 110°C, and then at 0.1°C·min -1 Heating up to 250°C, and finally at 5°C·min -1 Raise the tempe...

Embodiment 3

[0038] Take the specific surface area as 350m 2 g -1 , the pore volume is 1.02cm 3 g -1 , with an average pore diameter of 7.63nm on an alumina support, impregnating the ethanol solution of ammonium silicofluoride onto the alumina support, drying and calcining to obtain SiO with a silicon mass fraction of 3%. 2 / Al 2 o 3 Carrier; take 137.6g of nickel nitrate and 2.8g of urea to prepare 100ml of nickel salt solution; take 60ml of the prepared nickel salt solution and impregnate it into 50g of SiO with a silicon mass fraction of 3% above 2 / Al 2 o 3 In the carrier, stir well at room temperature, seal it in the container and let it stand for 3 hours; place the sealed container with the sample in a blast oven at 95°C and heat it for 7 hours; then open the container, and dry the sample in a blast oven at 90°C Dry for 3 hours, then heat up to 120°C and dry for 12 hours; then dry in air atmosphere at 2°C·min -1 Heating up to 110°C, and then at 1°C·min -1 Heating up to 250°C...

PUM

| Property | Measurement | Unit |

|---|---|---|

| specific surface area | aaaaa | aaaaa |

| pore size | aaaaa | aaaaa |

| specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com