35kV shielding type separable connector and expansion method thereof

A separate connector and shielding type technology, applied in the direction of connection, conductive connection, electrical component connection, etc., can solve problems such as insufficient insulation strength, strict installation process requirements, deformation of the front and rear insertion interfaces, etc., to avoid uneven spraying and conductive Good performance, the effect of improving electrical performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

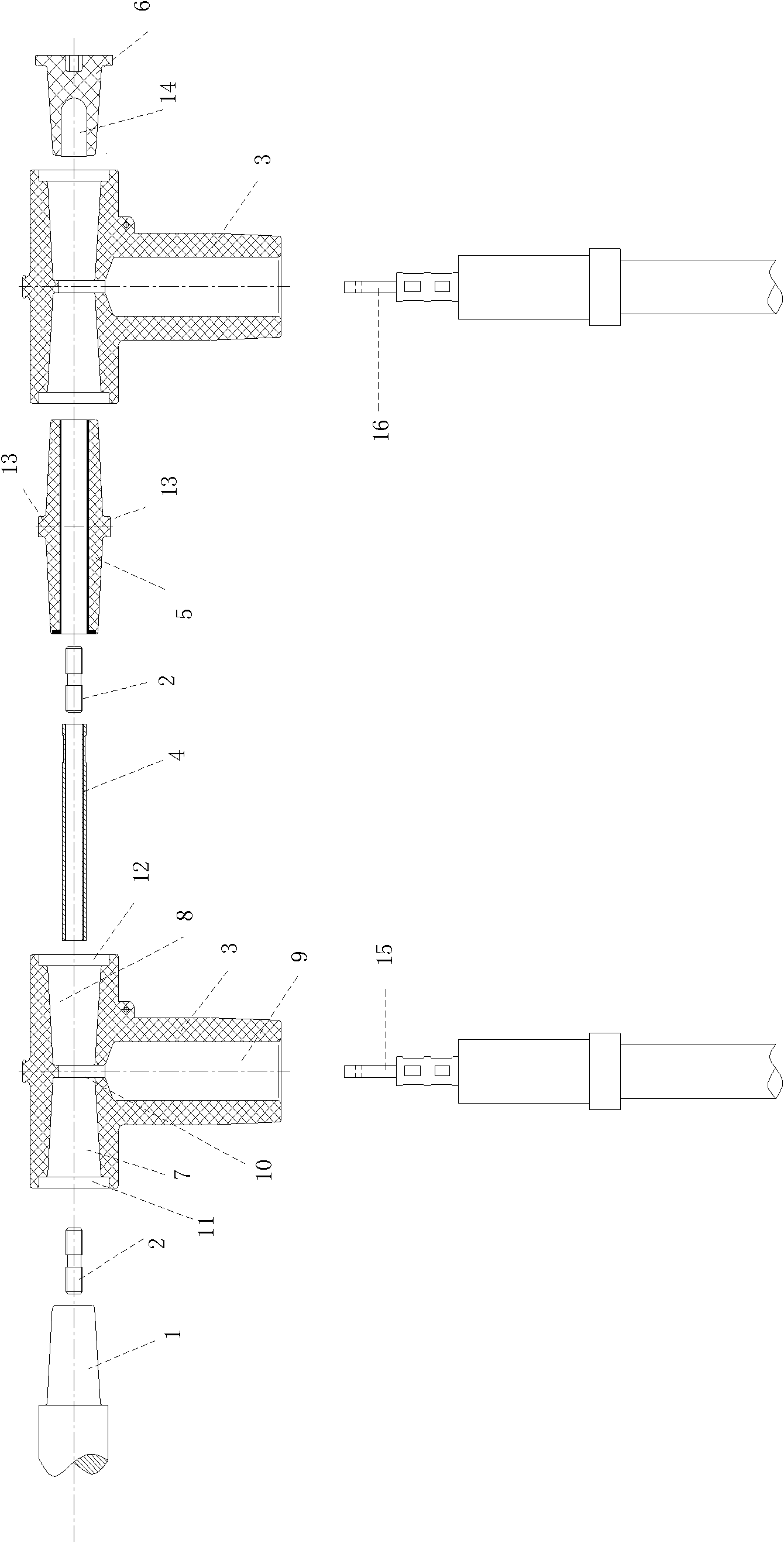

[0035] The exploded view of the 35kV shielded separable connector of the present invention for two-stage expansion is as follows figure 1 As shown, it includes two identical "T"-shaped separable connectors 3 and an intermediate connector, which connects the two "T"-shaped separable connectors; the horizontal part of the "T"-shaped separable connector 3 A first cavity 7 and a second cavity 8 that communicate with each other and have the same shape are provided along the horizontal direction. The first cavity 7 and the second cavity 8 pass through the horizontal part of the "T"-shaped separable connector, and the vertical part A third cavity 9 is provided along the vertical direction, and the "T"-shaped separable connector is left-right symmetrical with respect to the longitudinal axis of the third cavity 9; a conductive unit 10 is prefabricated in the "T"-shaped separable connector, and the conductive unit 10 is arranged between the first cavity and the second cavity, and commu...

Embodiment 2

[0045] The 35kV shielded separable connector of the present invention can also be used for multi-level expansion, and the specific steps are as follows:

[0046] In the first step, cables are inserted into the third cavities of all "T"-shaped separable connectors, and the cables are inserted into the conductive units through conductive terminals;

[0047] In the second step, connect the first cavity of a "T"-shaped separable connector to the switch cabinet bushing, and connect a conductive rod to the switch cabinet conductor through the connector;

[0048] In the third step, insert the left end of the insulating jacket from the second cavity of the "T"-shaped separable connector in the second step, and put it on the outside of the conductive rod;

[0049] The fourth step is to insert the first cavity of a "T"-shaped separable connector into the right end of the newly connected insulating jacket, and connect another conductive rod to the newly connected conductive rod through t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com