Extraction process for high-purity polysaccharides of tricholoma matsutake

A technology of matsutake polysaccharide and extraction process, which is applied in the field of high-purity matsutake polysaccharide extraction technology, can solve problems affecting the development of matsutake polysaccharide products, achieve the effects of retaining activity, increasing polysaccharide yield, and improving economic benefits

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

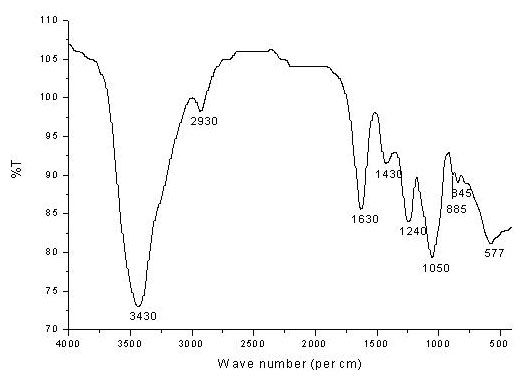

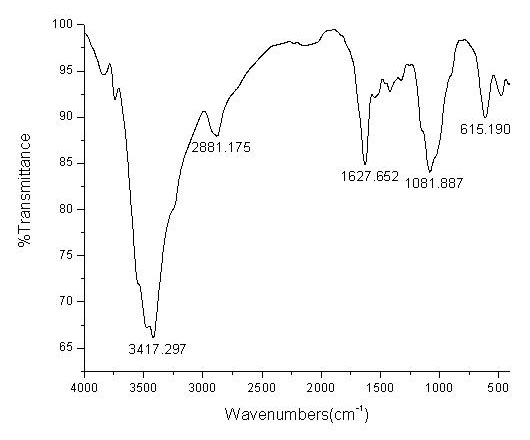

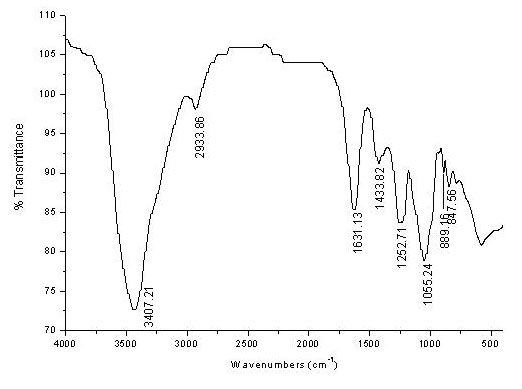

Image

Examples

Embodiment 1

[0022] 1) Cleaning: Take 100g of Matsutake, wash tap water, remove the residual dirt, and then dry it to the constant weight;

[0023] 2) Crush: crushed Matsutake to 60 meters;

[0024] 3) Skin: Add 1L 40%ethanol to the crushed Matsutsu, soak it for 2h at 40 ° C, or soak overnight.

[0025] 4) Add the above ingredients to 1L of water, treat 1h ultrasonic, and the effect temperature is 30 ° C, and the power is 200 W;

[0026] 5) Step of water immersion: The liquid material after the ultrasound is treated with a boiling water bath for 1h, and the residue and insoluble objects are filtered;

[0027] 6) Concentration: The polysaccharide mother solution from boiling water is concentrated to 1 / 5 of the original volume at 40 ° C and the vacuum-0.06MPa;

[0028] 7) Slowly add ethanol to the concentrated solution, so that the concentration of the solution ethanol is 60%, set up at 4 ° C for 10 minutes, 4000rpm centrifugal for 10 minutes, and after cleaning without water ethanol, the vacuum...

Embodiment 2

[0031] 1) Cleaning: Take 200g of Matsutake, wash tap water, remove the residual dirt, and then dry it to the constant weight;

[0032] 2) Crush: crushed Matsutake to 80 meters;

[0033] 3) Skin: Add 1L 60%ethanol to the crushed Matsutra, soak it for 2h at 60 ° C, or soak overnight.

[0034] 4) Add the above ingredients to 1L of water, treat 1.5h by ultrasound, the effect temperature is 45 ° C, and the power is 350 W;

[0035] 5) Step of water immersion: The liquid material after the ultrasound is treated with a boiling water bath for 2h, and the residue and insoluble objects are filtered;

[0036] 6) Concentration: The polysaccharide parent liquid that is extracted from boiling water is condensed to 1 / 8 of the original volume at 55 ° C and the vacuum-0.06MPa;

[0037] 7) Slowly add ethanol to the concentrated solution, so that the concentration of the solution ethanol is 80%, set up at 4 ° C for 10 minutes, 4000rpm centrifugal for 10 minutes, after cleaning without water ethanol, ...

Embodiment 3

[0040] 1) Cleaning: Take 400g of Matsutake, wash tap water, remove the residual dirt, and then dry it to the constant weight;

[0041] 2) Crush: crushed Matsutake to 100 meters;

[0042] 3) Skill: 1L 80%ethanol is added to the crushed Matsutsu, soaked in 80 ° C for 2h, or soaked overnight.

[0043] 4) Add the above ingredients to 1L of water, treat the ultrasound 2h, the effect temperature is 60 ° C, and the power is 500 w;

[0044] 5) Water immersion: The liquid material after the ultrasonic treatment is used for boiling water bath for 4h, filtering the residue and insoluble objects;

[0045] 6) Concentration: The polysaccharide parent liquid that is extracted from boiling water is concentrated to 1 / 10 of the original volume at 70 ° C and the vacuum-0.06MPa;

[0046] 7) Slowly add ethanol to the concentrated solution, so that the concentration of the solution ethanol is 95%, set up at 4 ° C for 10 minutes, 4000rpm centrifugal 10 minutes. After cleaning without water ethanol, the ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com