Novel female die structure for necking pipe fittings

A technology of shrinking and concave die, applied in the field of pipe fittings processing, can solve the problems of arc-shaped error not easy to reshape, low processing accuracy, low processing efficiency, etc., to reduce friction and extrusion force, ensure shrinking accuracy, and improve processing accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

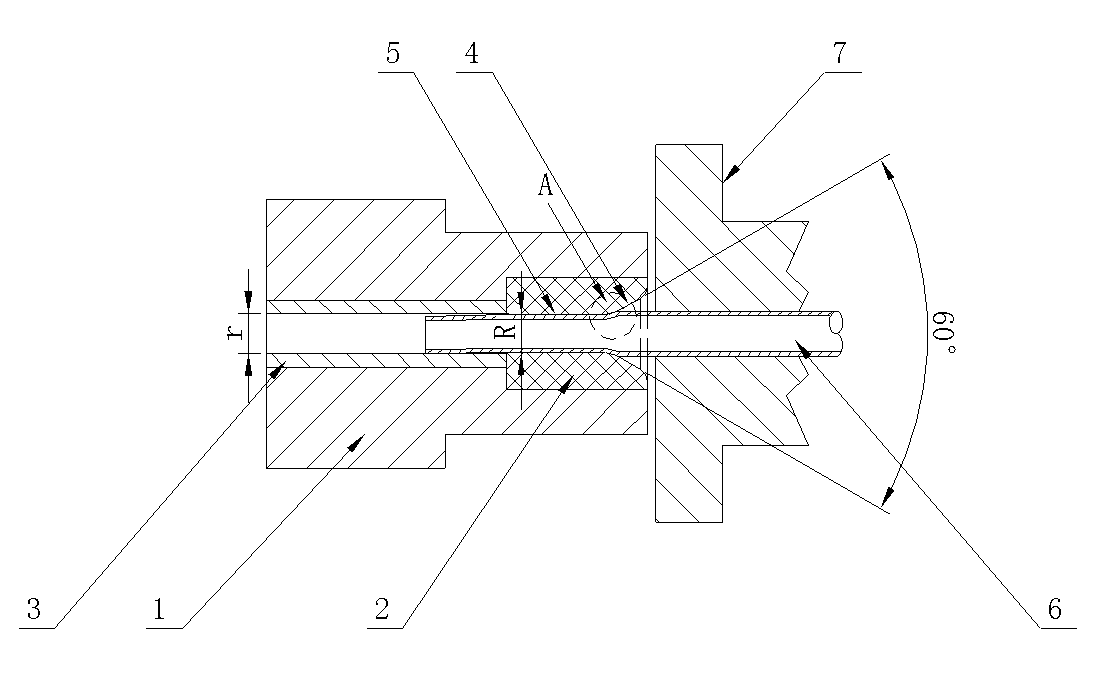

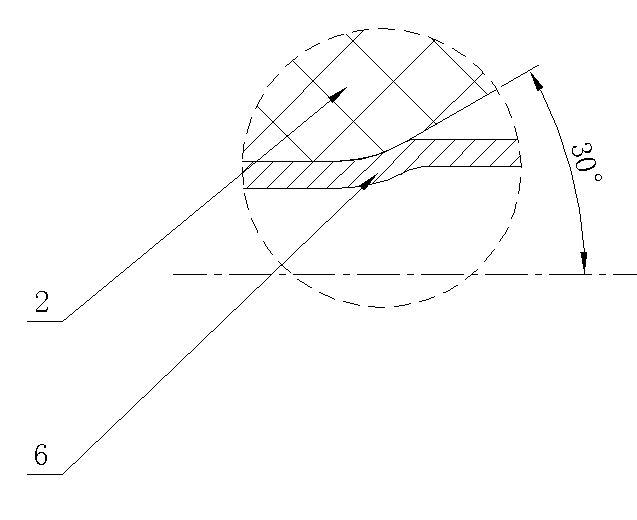

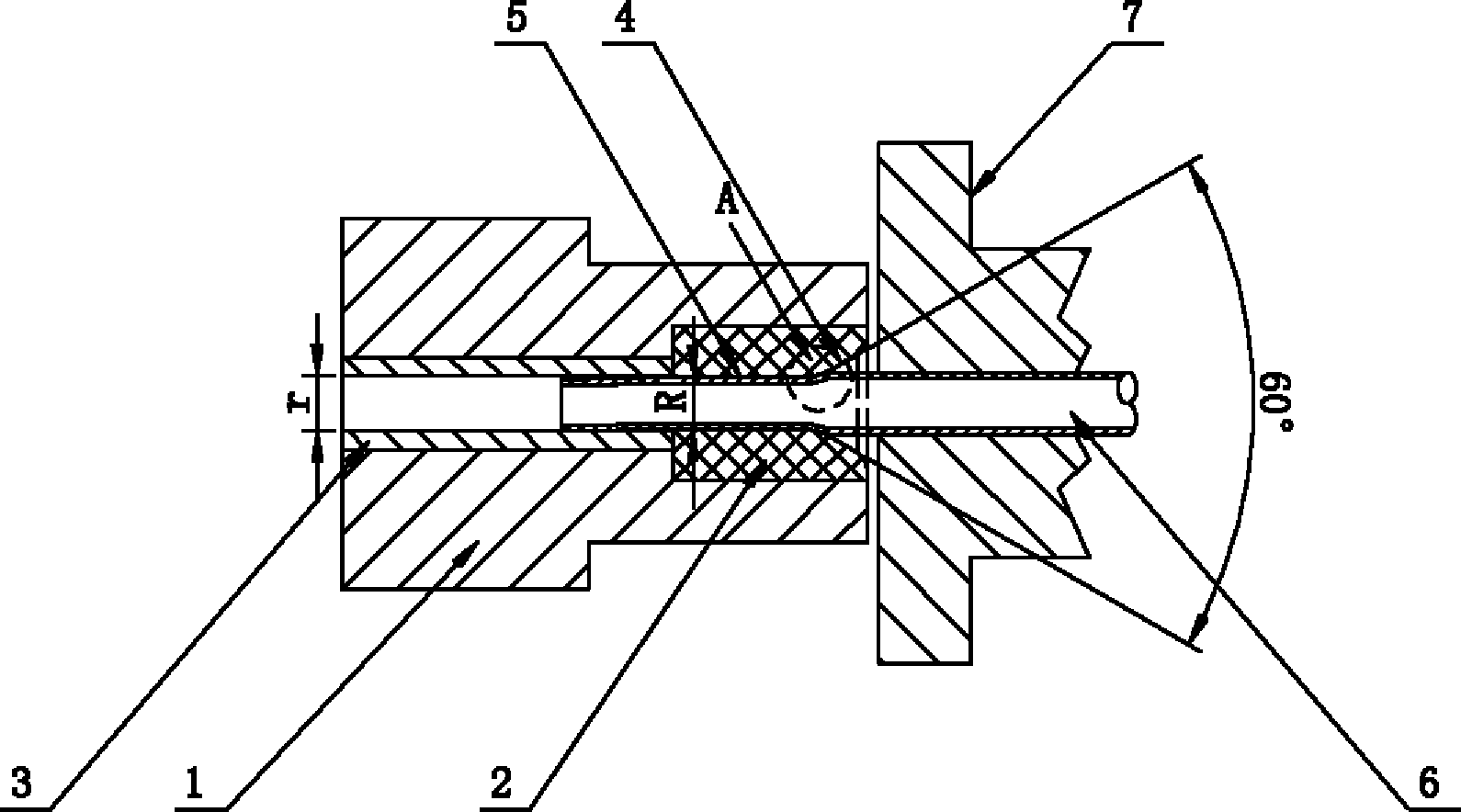

[0009] See figure 1 , figure 2 , the present invention includes a shrinking die body 1, the inlet end of the inner hole of the shrinking die body 1 is inlaid with a hard alloy sleeve 2, and the hard alloy sleeve 2 includes a pre-reduced diameter section 4 at the inlet end connected by a circular arc transition. Reduced diameter section 5; the pre-reduced diameter section 4 at the inlet end of the carbide sleeve 2 is conical bell-shaped; the taper of the pre-shrunk section 4 is 60°; the length of the reduced diameter section 5 is 15mm to 25mm; the rear end of the carbide sleeve 2 Alloy insert 3 is inlaid; the inner diameter r of the alloy insert 3 is slightly larger than the inner diameter R of the reduced diameter section of the carbide insert 2; 0.05mm.

[0010] The following specifically describes the process of using the structure of the present invention to carry out necking processing of pipe fittings: the pipe fitting 6 to be shrunk is fixed to the workpiece clamping ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com