Complete formula granulated feed for beef cattle and preparation method thereof

The technology of pellet feed and pellet feed is applied in the field of beef cattle full-price pellet feed and its preparation. The effect of the right energy content

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

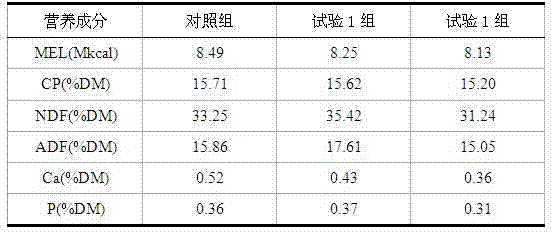

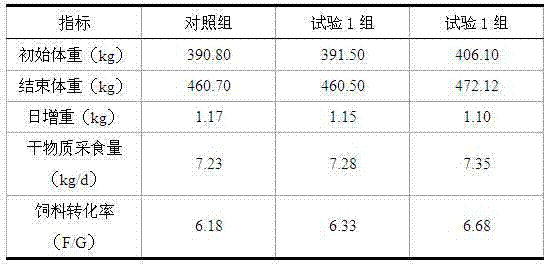

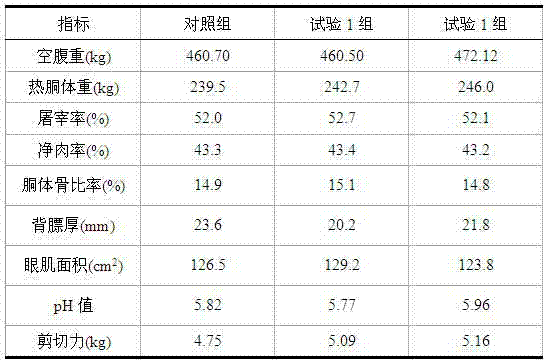

[0034] Embodiment 1: Beef cattle non-grain feed full-price pellet feeding test of beef cattle

[0035] The full-price granular feed for beef cattle of the present invention is made of the following components in formula quantity by weight:

[0036] Wheat husk 30%, brewer's grain 18%, malt root 15%, secondary powder 10%, soybean hulls 9%, palm meal 7%, molasses 6%, urea 2%, premix 2%, bentonite 1%.

[0037] The production process is as follows: the wheat husk and malt root are respectively pulverized with a hammer mill to a particle size of 0.5-5.0 mm, and other materials are sieved to a particle size of 3-10 mm. Stir evenly in the mixer according to the above formula, and use the HKJ-200 granulator to directly compress the granules. The granulator requires 15 kilowatts of power and the production capacity is 500-800kg / hour. The total water content of the mixture is 17% to 24%, which is beneficial to granulation and does not require additional water or steam. The speed of the ...

Embodiment 2

[0051] The full-price granular feed for beef cattle of the present invention is made of the following components in formula quantity by weight:

[0052] Wheat husk 35%, brewer's grain 15%, malt root 12%, secondary powder 8%, soybean hulls 15%, palm meal 5%, molasses 6%, urea 1%, premix 2%, bentonite 1%.

[0053] The non-grain feed full-price pellets for beef cattle are prepared as follows:

[0054] (1) Crushing and stirring Take the formula quantity of wheat husks and malt roots and grind them with a hammer mill respectively, with a particle size of 0.5-5.0 mm. Other materials are sieved with a particle size of 0.3-1.0 mm. Stir evenly in a mixer according to the above formula.

[0055] (2) Granulation Use a granulator to directly compress granules. Tests have shown that the total water content of the mixture of the above formula is 17% to 24%, which is conducive to granulation and does not require additional water or steam.

[0056] (3) Gap between die and roller

[0057] T...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com