Automatic tamper type waste filling hydraulic support

A hydraulic support and self-tamping technology, which is applied to fillings, mine roof supports, safety devices, etc., can solve problems such as waste of resources, ground subsidence, and disappearance of compaction effects, so as to improve filling density and support strength , the effect of preventing ground subsidence

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

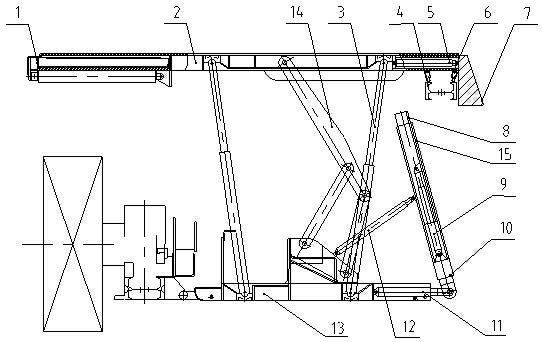

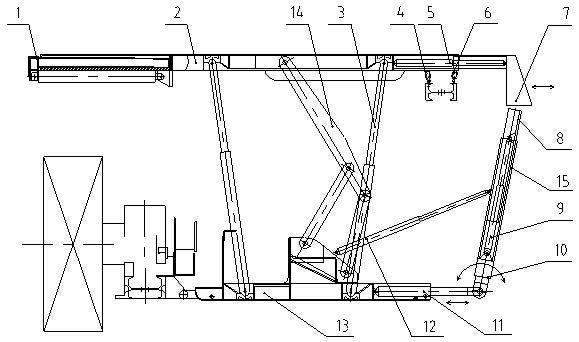

[0032] like figure 1 As shown, the present invention includes a base 13 and a top beam 2, and the base 13 and the top beam 2 are connected and supported by four columns 3, and the columns 3 adopt hydraulic cylinders, and a supporting linkage mechanism is also provided between the base 13 and the top beam 2 14. When the hydraulic cylinder of the column 3 expands and contracts, the supporting link mechanism 14 rises or falls accordingly, playing the role of stabilizing the support.

[0033] The front beam 1 is connected to the left side of the roof beam 2 . The right end of the top beam 2 is provided with a chute, which is slidingly connected with an inner telescopic extruding shovel 7, and the inner telescopic extruding shovel 7 is driven by a telescopic jack 5 arranged horizontally for reciprocating extrusion. Hang the scraper conveyor 4 with the ring chain 6 below the top beam 2 right sides, and the scraper conveyor 4 has a hole for leaking gangue.

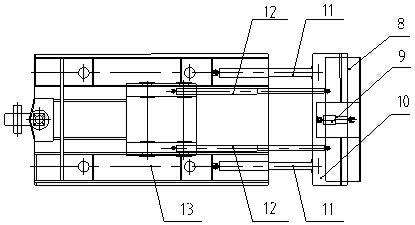

[0034] like figure 2 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com