Method for leaching vanadium slag in converter by electro-catalytic oxidation

A technology of electrocatalytic oxidation and converter vanadium slag, applied in electrodes, electrolytic components, electrolytic process, etc., can solve the problems of low vanadium extraction rate, low vanadium pentoxide yield, low vanadium oxysulfate leaching rate, etc. The process conditions are pollution-free, the recovery rate is high, and the process conditions are mild.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

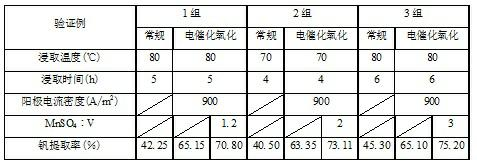

Examples

Embodiment Construction

[0010] The method for leaching converter vanadium slag by electrocatalytic oxidation comprises the step (1) of mixing sulfuric acid and converter vanadium slag to prepare ore slurry. In the step (1) of the present invention, the percentage concentration of sulfuric acid is 30% to 50%, and the converter vanadium slag is in the form of powder after passing through a 200 mesh (0.075mm) sieve; the mass ratio of sulfuric acid to the vanadium contained in the converter vanadium slag is is 80:1.5~2; the following steps are:

[0011] (2) Put the ore slurry obtained in step (1) in the leaching tank, and turn on the power to carry out the electrocatalytic oxidation reaction; wherein, the anode current density is 400-1000A / m 2 , the leaching temperature is 25-100°C, and the leaching time is 2-10h (those skilled in the art know that the length of the leaching time is related to the size of the anode current density and the leaching temperature. When the temperature is higher, the leachin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com