Magnetic sheet composition, magnetic sheet, and process for producing magnetic sheet

A technology of magnetic sheet and composition, applied in the direction of magnetic objects, magnetic materials, inorganic materials, etc., can solve the problems of poor curing and reduced reactivity, and achieve no corrosion, no unpleasant odor, low temperature-fast curing sexual effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

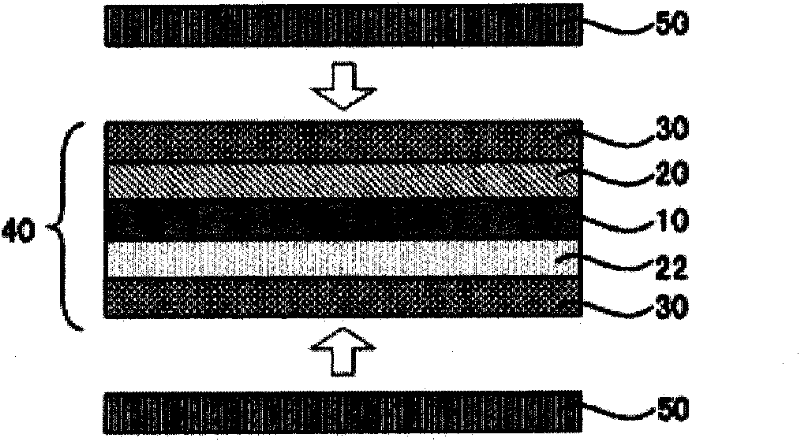

[0162] The preparation method of the magnetic sheet of the present invention is not particularly limited, and can be appropriately selected according to the purpose, but preferably can be prepared by the preparation method of the magnetic sheet of the present invention described below.

[0163] (Manufacturing method of magnetic sheet)

[0164] The production method of the magnetic sheet of the present invention includes at least a magnetic layer formation step and a shape transfer step, and may further include other steps appropriately selected as necessary.

[0165]

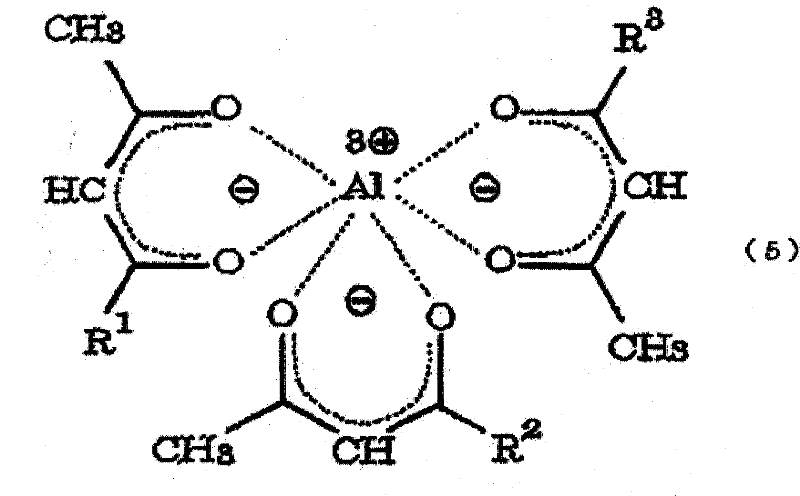

[0166] The magnetic layer forming step is to form a magnetic sheet containing at least an aluminum chelate latent curing agent, a silanol compound or an alkoxysilane compound represented by the following formula (A), an epoxy resin, an acrylic resin and a magnetic powder. A step of molding the composition to form a magnetic layer.

[0167] (Chemical formula 9)

[0168] (Ar) m Si(OR) n Formula (A)

[0...

Embodiment 1

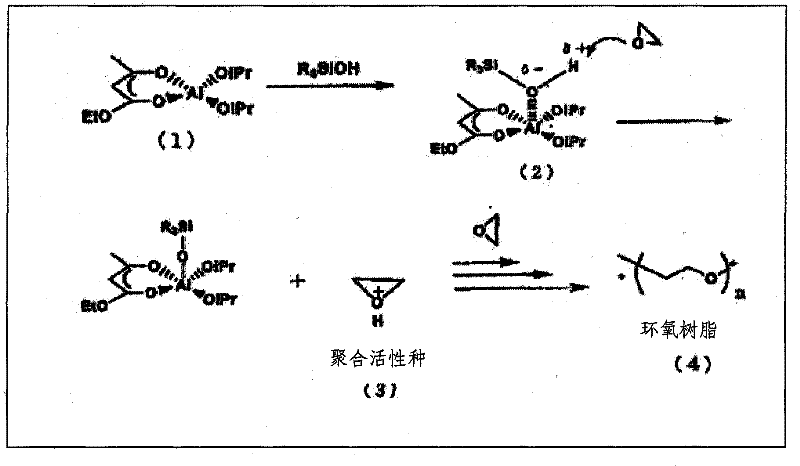

[0200] -Preparation of aluminum chelating agent class latent curing agent (1)-

[0201] Put 800 parts by mass of distilled water, 0.05 parts by mass of a surfactant (Niyu Rex R-T, NOF Co., Ltd.) and 4 parts by mass of polyvinyl alcohol (PVA-205, from Kuraray Co., Ltd.) as a dispersant into a thermometer with a thermometer In a 3-liter interfacial polymerization vessel, mix well. Then drop into the oil phase solution into the solution, emulsify and mix it with a homogenizer (10000rpm / 5 minutes), and carry out interfacial polymerization at 80° C. for 6 hours; 24% isopropanol solution of aluminum acetylacetoacetate (aluminum chelate D, Chuanken Fine Chemical Co., Ltd.), 70 parts by mass of methylene diphenyl-4,4'-diisocyanate (3mol) Methylolpropane (1mol) addition product (D-109, Mitsui Takeda Chemical Co., Ltd.), 30 parts by mass of divinylbenzene (Merck Company) and 0.30 parts by mass of free radical polymerization initiator (Peroyl L, NOF Corporation ) obtained by being diss...

Embodiment 2~24

[0211] -Preparation of Magnetic Sheet-

[0212] In Example 1, the consumption of the aluminum chelate latent curing agent (1), the consumption of the triphenylsilanol (TPS), the pressure holding temperature, the pressure holding time And at least one of the pressurization time was changed as shown in Tables 1 to 4, except that it was the same as in Example 1 to obtain a magnetic sheet.

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com