Three-dimensional orthotropic carbon fiber reinforced aluminum-based composite material and preparation method thereof

A technology for reinforcing aluminum matrix and composite materials, which is applied in the field of three-dimensional orthogonal carbon fiber reinforced aluminum matrix composite materials and its preparation, and achieves the effects of good bonding, compact structure and excellent comprehensive performance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

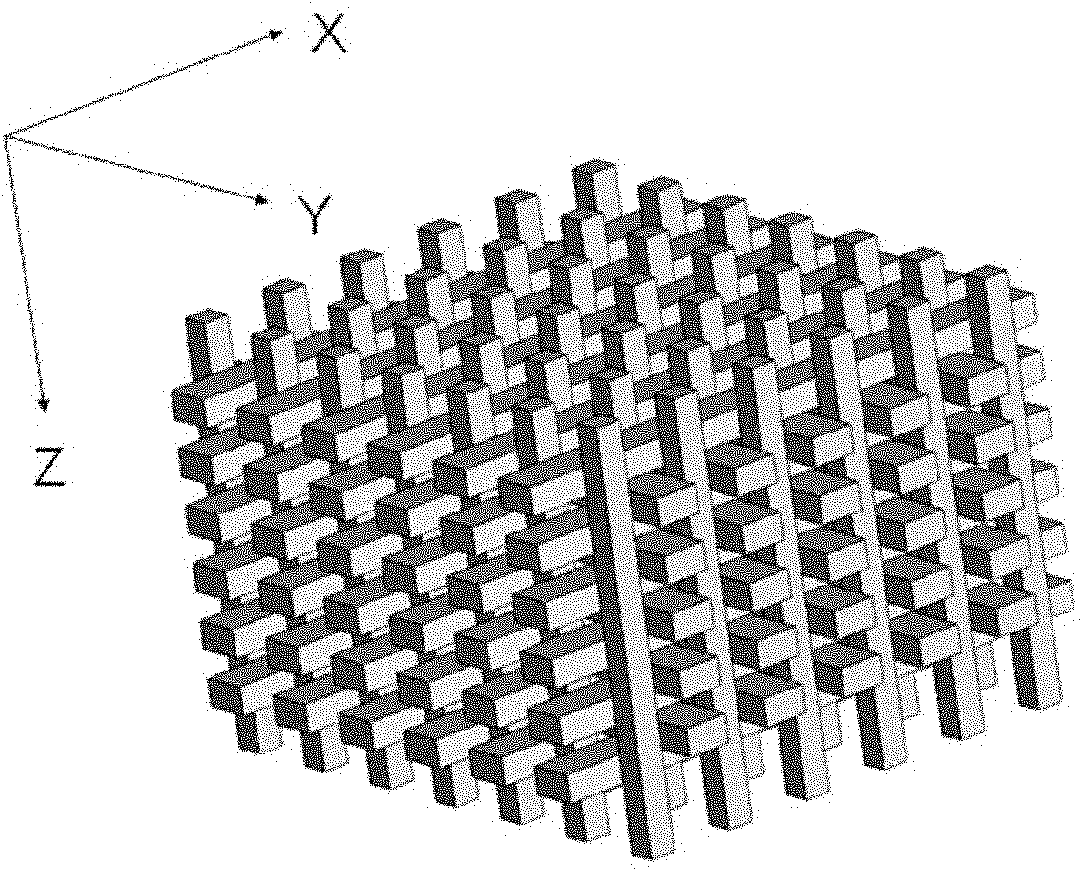

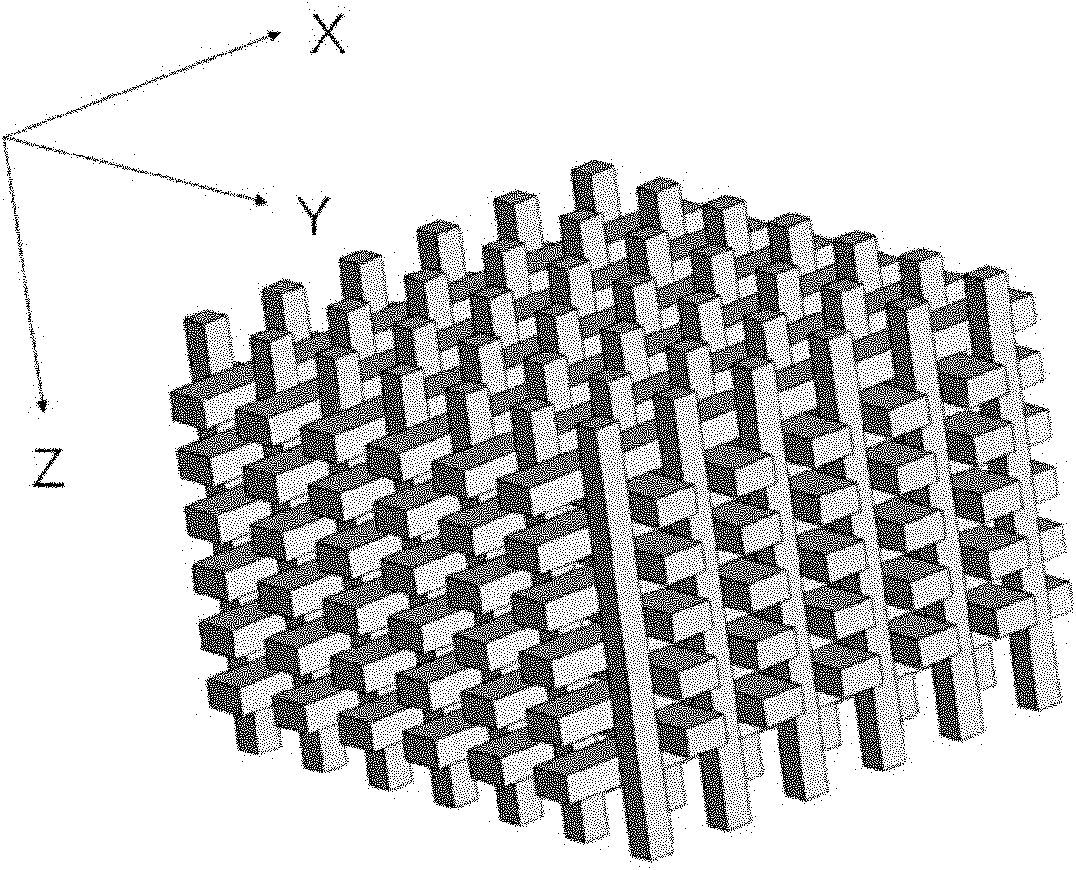

Image

Examples

Embodiment 1

[0015] The warp, weft and Z-direction yarns of the three-dimensional orthogonal carbon fiber reinforcement are all T300. Carbon fiber accounts for about 40% of the volume fraction of the composite. The base is made of pure aluminum. The carbon fiber preheating temperature is 400°C, the pouring temperature is 740°C, the extrusion pressure is 10MPa, and the holding time is 60 seconds. The structure of the three-dimensional orthogonal carbon fiber reinforced aluminum matrix composite is dense, the carbon fiber is well bonded to the matrix, and the carbon fiber is evenly distributed without deviation. Poly and bend. The composite material has a strength of 304MPa along the warp and weft directions.

Embodiment 2

[0017] The warp, weft and Z-direction yarns of the three-dimensional orthogonal carbon fiber reinforcement are all T700. Carbon fiber accounts for about 50% of the volume fraction of the composite material. The substrate is made of aluminum alloy ZL101. The carbon fiber preheating temperature is 500°C, the pouring temperature is 750°C, the extrusion pressure is 30MPa, and the holding time is 60 seconds. The structure of the three-dimensional orthogonal carbon fiber reinforced aluminum matrix composite is dense, the carbon fiber is well bonded to the matrix, and the carbon fiber is evenly distributed without deviation. Gathering and bending phenomena. The composite material has a strength of 590MPa along the warp and weft directions.

Embodiment 3

[0019] The warp yarn of the three-dimensional orthogonal carbon fiber reinforcement is T700, and the weft yarn and Z-direction yarn are T300. Carbon fiber accounts for nearly 60% of the volume fraction of the composite material. The substrate is made of aluminum alloy ZL102. The carbon fiber preheating temperature is 600°C, the pouring temperature is 760°C, the extrusion pressure is 50MPa, and the holding time is 60 seconds. The structure of the three-dimensional orthogonal carbon fiber reinforced aluminum matrix composite is dense, the carbon fiber is well bonded to the matrix, and the carbon fiber is evenly distributed without deviation. Gathering and bending phenomena. The strength of the composite material along the warp direction is 638MPa, and the strength along the weft direction is 358MPa.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com