Method for producing fructooligosaccharide by using transfructosylase

A technology of fructosyltransferase and fructooligosaccharides, applied in the field of fructooligosaccharides production, can solve the problems of unfavorable fructooligosaccharides accumulation, production limitation, low activity, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

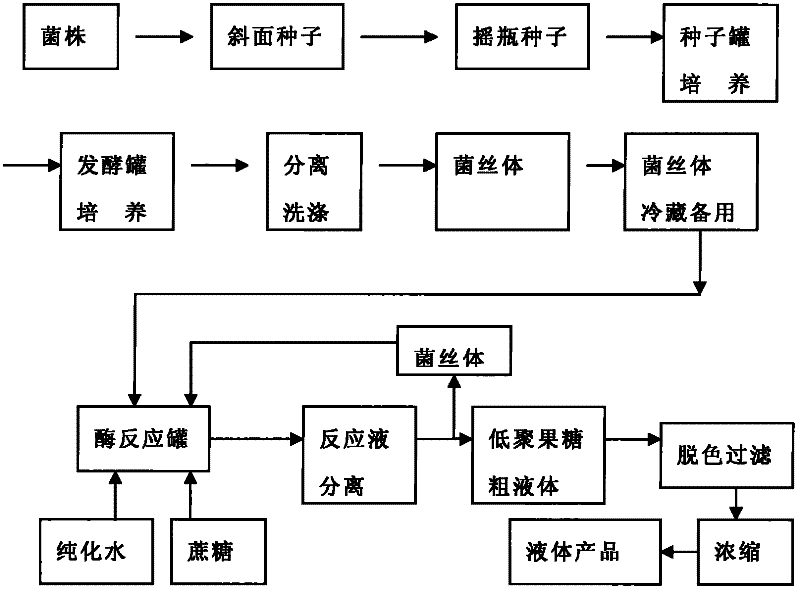

Image

Examples

Embodiment 1

[0021] The Penicillium spp. was inserted into a fermentation tank containing 5% sucrose, 3.5% soybean meal, 0.5% corn meal culture solution 50L, culture conditions were 30℃, PH5.20, aeration rate 200ml / min, stirring speed 150r / min, After 20 hours of fermentation, a large amount of mycelium was obtained by centrifugal separation, and the enzyme activity was detected by HPLC. The mycelium was put into the enzyme reaction tank of 45% sucrose solution according to the enzyme amount of 3500u / kg sucrose, and the reaction temperature was controlled at 30℃, PH5. 2±0.2, react for 24 hours, the content of oligofructose reached above 50% by HPLC, the reaction solution is separated by ceramic microfiltration membrane to separate the mycelium to obtain a transparent light yellow oligofructose crude liquid, which is decolorized by macroporous resin and concentrated Fructooligosaccharides with a chromaticity of less than 0.05 are obtained.

Embodiment 2

[0023] The penicillium species was connected to a fermentation tank containing 8% sucrose, 4.0% soybean meal, 1.5% corn meal culture solution 5000L, the culture condition was 32℃, the aeration rate was 500ml / min, the stirring speed was 120r / min, and the fermentation was carried out for 24 hours. , Centrifugal separation to obtain a large number of mycelium, detect the enzyme activity by HPLC, put the mycelium into the enzyme reaction tank of 50% sucrose solution according to the enzyme amount of 4500u / kg sucrose, control the reaction temperature of 31 ℃, pH 6.0 ± 0.2, After reacting for 20 hours, the content of fructo-oligosaccharides reached more than 50% by HPLC. The reaction liquid was separated by ceramic microfiltration membrane to obtain a transparent light yellow fructo-oligosaccharide crude liquid, which was decolorized by macroporous resin and concentrated to obtain a color less than 0.05 fructooligosaccharide.

Embodiment 3

[0025] The Penicillium spp. strain was inserted into a fermenter containing 20% potato, 3% sucrose, 0.2% potassium dihydrogen phosphate, 0.3% magnesium sulfate, 0.3% sodium nitrate, 0.2% agar culture solution 50L, and the culture condition was 27°C. The aeration rate is 300ml / min, the stirring speed is 100r / min, after 50 hours of fermentation, a large amount of mycelium is obtained by centrifugal separation, and the enzyme activity is detected by HPLC. The mycelium is poured into a 40% sucrose solution at an enzyme amount of 3000u / kg. Enzyme reaction tank, control the reaction temperature at 27℃, pH 6.3±0.2, react for 30 hours, detect the oligofructose content by HPLC to reach more than 50%, the reaction liquid is separated by ceramic microfiltration membrane to separate the mycelium, and the transparent light yellow is obtained. The crude polyfructose liquid is decolorized by a macroporous resin and concentrated to obtain fructooligosaccharides with a color less than 0.05.

PUM

| Property | Measurement | Unit |

|---|---|---|

| heating value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com