Water-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion and synthesis method thereof

A water-based epoxy and anti-rust emulsion technology, used in epoxy resin coatings, anti-corrosion coatings, coatings, etc., can solve the problem of no performance test, no way to know the advantages and disadvantages of emulsion performance, no detailed introduction of anti-rust emulsion formula and Process and other issues, to achieve the effect of inhibiting flash corrosion, preventing demulsification, and low construction requirements

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

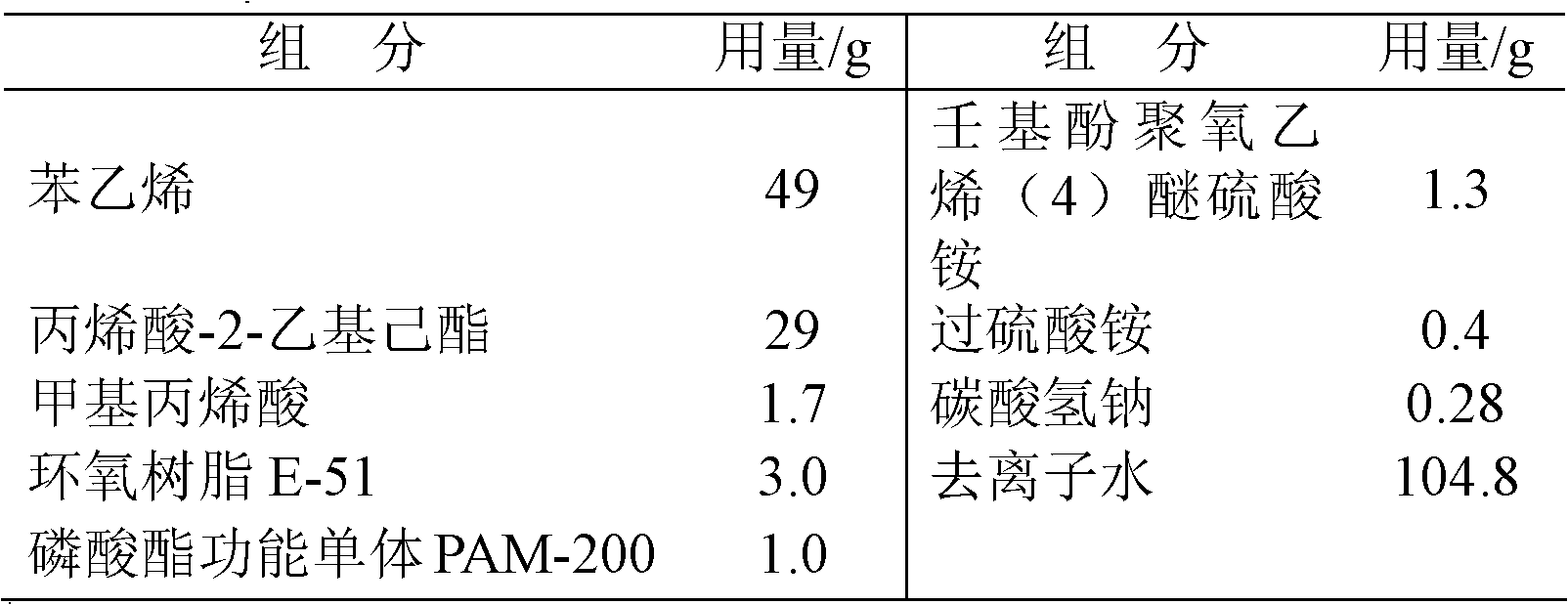

[0036] The raw material formula of water-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion is shown in Table 1:

[0037] Table 1 Formula of water-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion

[0038]

[0039] Its synthetic method:

[0040] ① Preparation of pre-emulsion: Add 1 g of nonylphenol polyoxyethylene (4) ether ammonium sulfate, 40 g of deionized water, and 1 g of phosphate ester functional monomer PAM-2001 g into a pre-emulsification kettle equipped with a stirring device. After stirring evenly, Add 3g of epoxy resin, 40g of styrene, 38g of butyl acrylate, and 1.7g of methacrylic acid, and stir for 30 minutes to obtain a pre-emulsion.

[0041] ② Add 0.3 g of nonylphenol polyoxyethylene (4) ether ammonium sulfate, 40 g of deionized water, and 0.28 g of sodium bicarbonate into the reaction kettle equipped with a stirring device, a reflux condenser and a dropping funnel, start stirring and raise the temperatur...

Embodiment 2

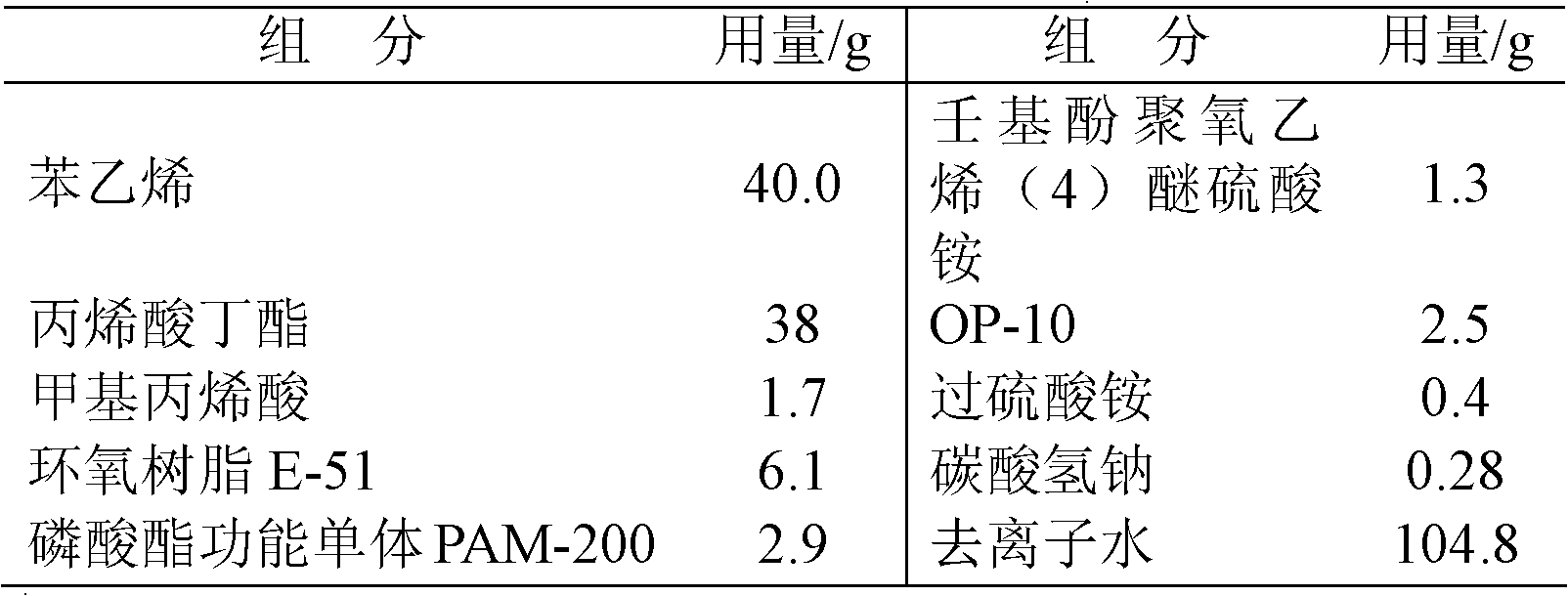

[0046] The raw material formula of water-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion is shown in Table 2:

[0047] Table 2 Waterborne epoxy modified phosphorus-containing styrene-acrylic antirust emulsion formula

[0048]

[0049] Its synthetic method:

[0050] ① Preparation of pre-emulsion: Add 1 g of nonylphenol polyoxyethylene (4) ether ammonium sulfate, 2.5 g of OP-10 emulsifier, 40 g of deionized water, and PAM -2002.9g, after stirring evenly, add 6.1g of epoxy resin, 40g of styrene, 38g of butyl acrylate, and 1.7g of methacrylic acid, and stir for 30min to obtain a pre-emulsion.

[0051] ② Add 0.3 g of nonylphenol polyoxyethylene (4) ether ammonium sulfate, 40 g of deionized water, and 0.28 g of sodium bicarbonate into the reaction kettle equipped with a stirring device, a reflux condenser and a dropping funnel, start stirring and raise the temperature.

[0052] ③When the temperature rises to 60°C, add 0.27g and 8.6g of ammonium pers...

Embodiment 3

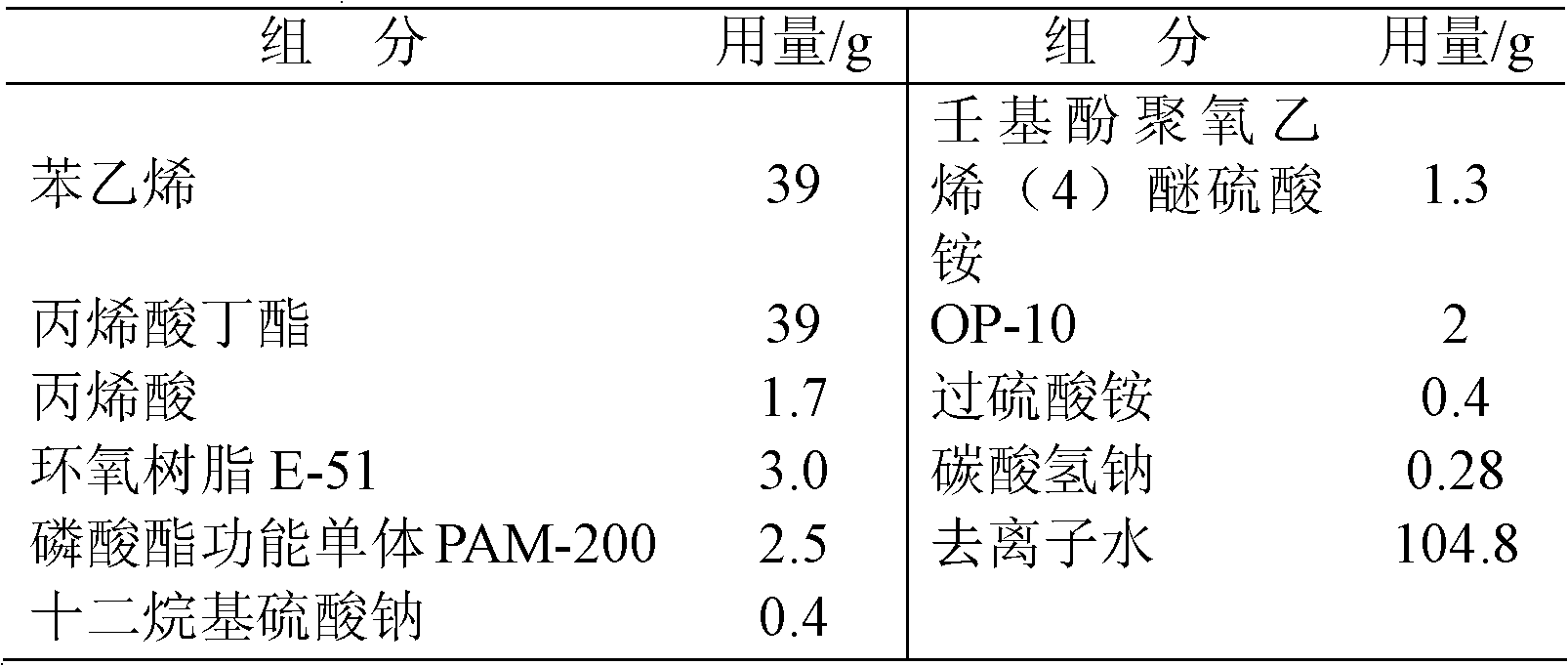

[0056] The raw material formula of water-based epoxy modified phosphorus-containing styrene-acrylic antirust emulsion is shown in Table 3:

[0057] Table 3 Waterborne epoxy modified phosphorus-containing styrene-acrylic antirust emulsion formula

[0058]

[0059] Its synthetic method:

[0060] ① Preparation of pre-emulsion: Add 1 g of nonylphenol polyoxyethylene (4) ether ammonium sulfate, 2 g of OP-10 emulsifier, 0.4 g of sodium lauryl sulfate, and deionized water into a pre-emulsification kettle equipped with a stirring device. 40g, 2.5g of phosphate ester functional monomer PAM-200, after stirring evenly, add 3g of epoxy resin, 40g of styrene, 38g of butyl acrylate, and 1.7g of methacrylic acid, and stir for 30min to obtain a pre-emulsion.

[0061] ② Add 0.3 g of nonylphenol polyoxyethylene (4) ether ammonium sulfate, 40 g of deionized water, and 0.28 g of sodium bicarbonate into the reaction kettle equipped with a stirring device, a reflux condenser and a dropping funn...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

| Viscosity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com