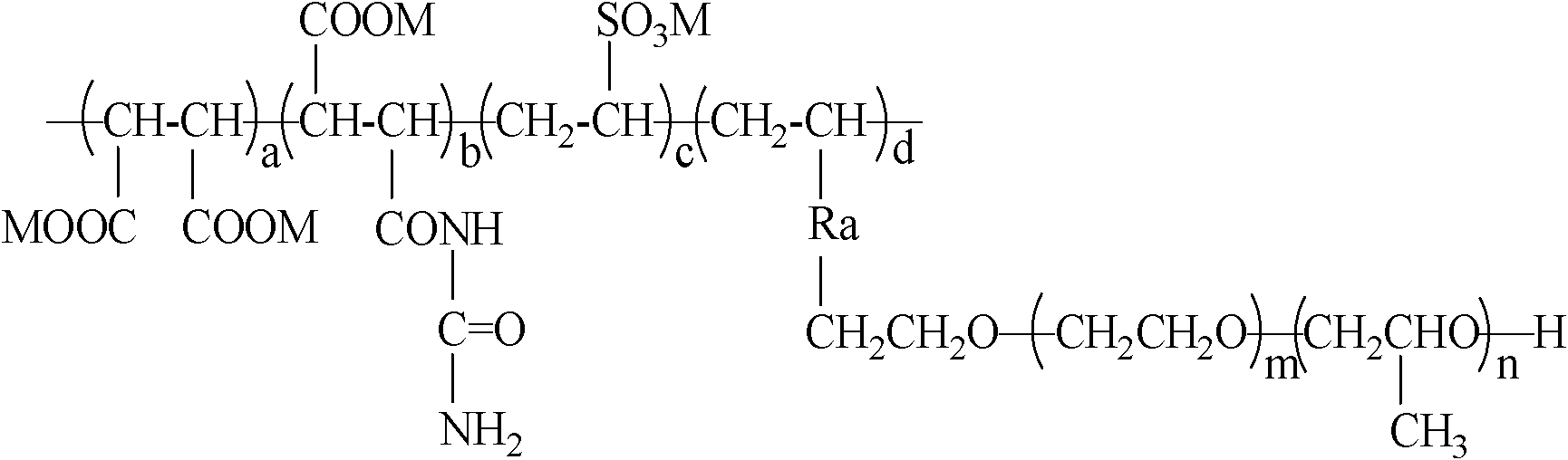

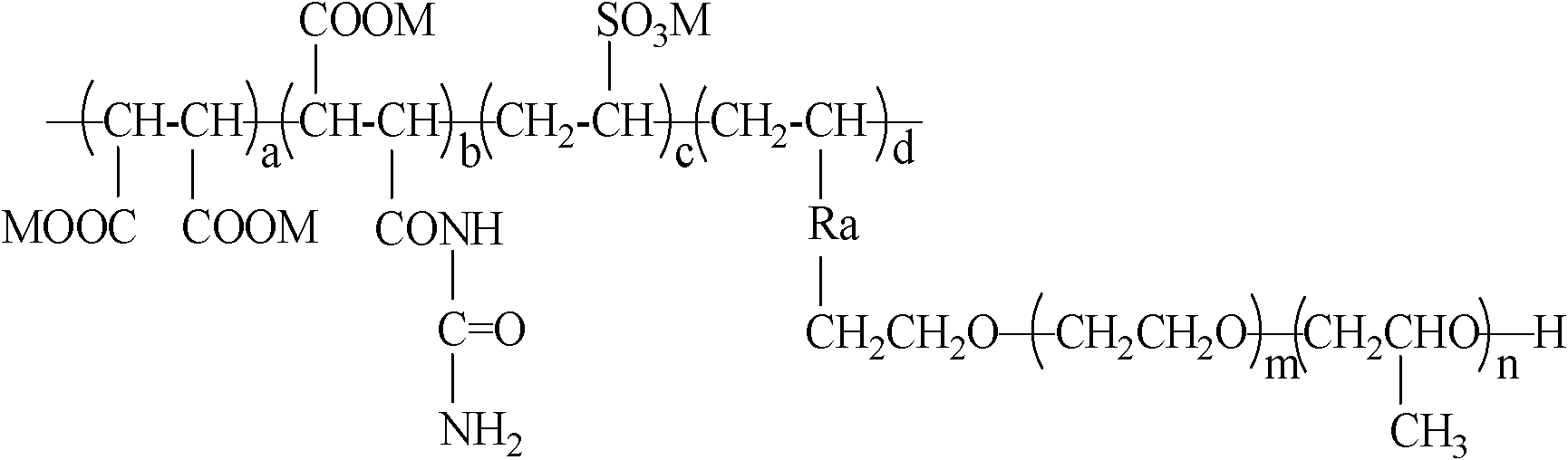

High-performance reinforcing agent for pile and preparation method thereof

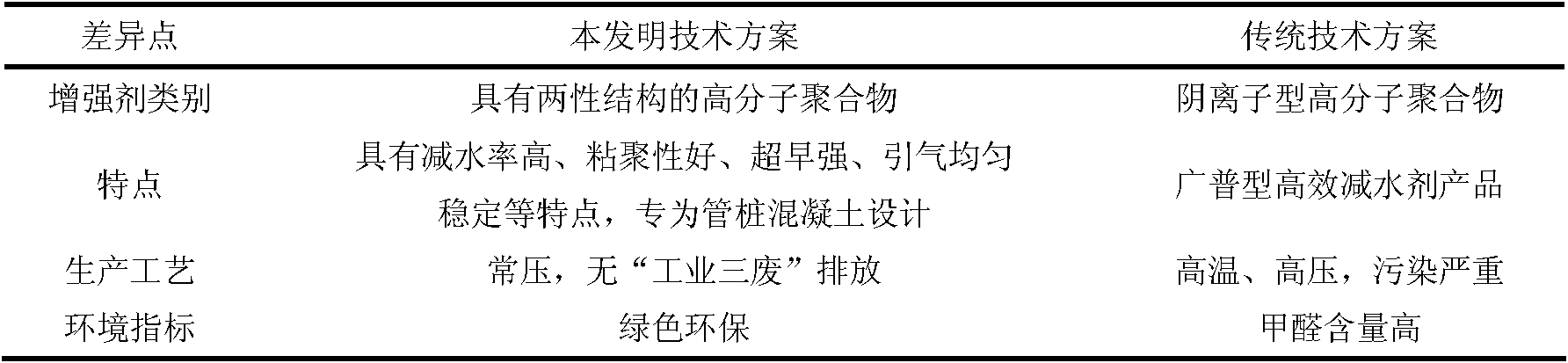

A reinforcing agent and high-performance technology, which is applied in the field of chemical building materials and construction, can solve problems such as the impact on the durability of finished pipe piles, and achieve the effects of good cohesion, uniform and stable air entrainment, and high water-reducing rate

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0027] (1) Amidation reaction: Add 60g of urea, 117.6g of maleic anhydride (or 139.2g of fumaric acid), and 2.66g of concentrated sulfuric acid into a four-neck flask, start the stirring device, and keep the temperature at 85°C for 2 hours to obtain amide small monomer.

[0028] (2) Copolymerization reaction: Weigh 48.0 g of small amide monomers, 6.4 g of sodium vinyl sulfonate and 160 g of TPEG with a molecular weight of 2500, and add them together with 100 g of water into a four-necked flask, and keep the temperature at 50°C. An aqueous solution of ammonium persulfate (5.36g ammonium persulfate+40g water) and an aqueous solution of isopropanol (1.07g isopropanol+40g water) were added dropwise, the time for adding was 2 hours, and the temperature was kept constant for 1.5 hours after the addition.

[0029] (3) Neutralization: cool down to 45°C, adjust the pH value in the range of 6.0 to 7.0 with sodium hydroxide, and obtain a colorless or light yellow clear solution with a co...

Embodiment 2

[0033] (1) Amidation reaction: Add 180 g of urea, 259.2 g of acrylic acid, and 11.0 g of p-toluenesulfonic acid into a four-necked flask, start the stirring device, and keep the temperature at 70° C. for 4 hours to obtain small amide monomers.

[0034] (2) Copolymerization reaction: Weigh 30.0 g of small amide monomers, 11.0 g of sodium vinyl sulfonate and 200 g of TPEG with a molecular weight of 10,000, add them together with 110 g of water into a four-necked flask, and keep the temperature at 70°C. The aqueous solution of hydrogen peroxide (32.1g30% hydrogen peroxide+30g water), the aqueous solution of sodium formate (3.62g sodium formate+60g water) were added dropwise respectively, the time for adding was 2 hours, and the temperature was kept constant for 4 hours after the addition.

[0035] (3) Neutralization: cool down to 45° C., adjust the pH value in the range of 6.0 to 7.0 with calcium hydroxide, obtain a colorless or light yellow clear solution with a concentration of ...

Embodiment 3

[0037] (1) Amidation reaction: Add 120kg of urea, 206.4kg of methacrylic acid, and 6.53kg of sulfamic acid into a 1000L reaction kettle, start the stirring blade, and keep the temperature at 80°C for 3 hours to obtain amide small monomers.

[0038](2) Copolymerization reaction: Weigh 281.6kg of small amide monomers, 105.6kg of sodium vinyl sulfonate and 1760kg of TPEG with a molecular weight of 8000, and add them into a 5000L reactor along with 800kg of water, and keep the temperature at 60°C. Add dropwise the aqueous solution of sodium azobisisobutylamidine hydrochloride (96.6kg sodium azobisisobutylamidine hydrochloride+500kg water), the aqueous solution of isooctyl 3-mercaptopropionate (23.6kg isooctyl 3-mercaptopropionate+ 500kg water), the time for dropping was 2 hours, and the temperature was kept constant for 2.5 hours after the dropping.

[0039] (3) Neutralization: the temperature is lowered to 45° C., and the pH value is adjusted in the range of 6.0 to 7.0 with potas...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Density | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

| Specific surface area | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com