Method and device for automatically controlling argon blowing quantity for steel ladle of continuous casting machine

A machine-steel, continuous casting technology, applied in electrical program control, program control in sequence/logic controllers, and manufacturing tools, etc., can solve the problems of ladle not blowing argon, ladle temperature in molten steel, environmental temperature adjustment, etc. , to improve the purity of molten steel, improve the effect of argon blowing, and reduce the effect of slag inclusion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

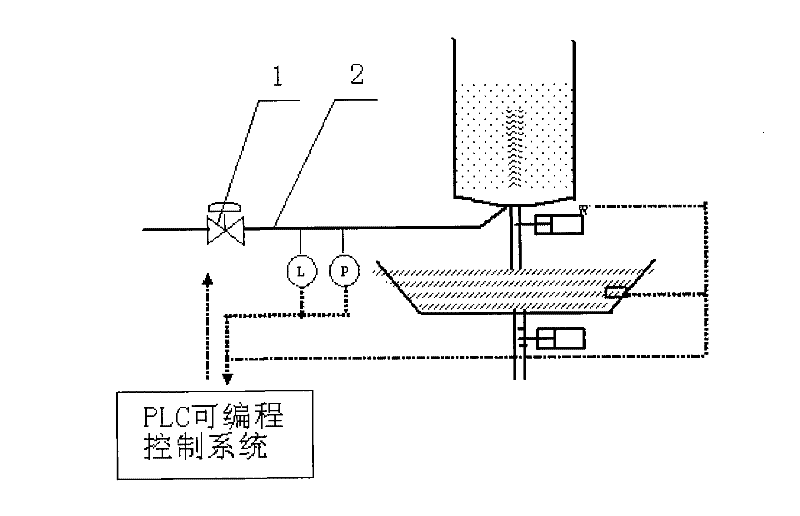

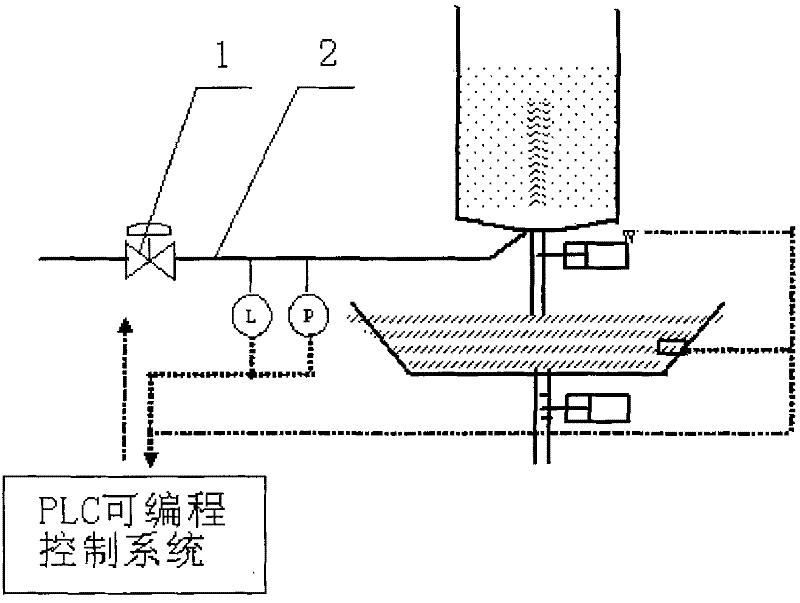

[0015] Since the ladle temperature measurement technology is mature, the temperature of the tundish can be monitored in real time. Therefore, argon blowing of the ladle is used to adjust in real time with the weight, and the controllable adjustment is made according to the temperature of the tundish to effectively reduce the inclusion of molten steel in the ladle during the casting process. Float up to improve the purity of molten steel.

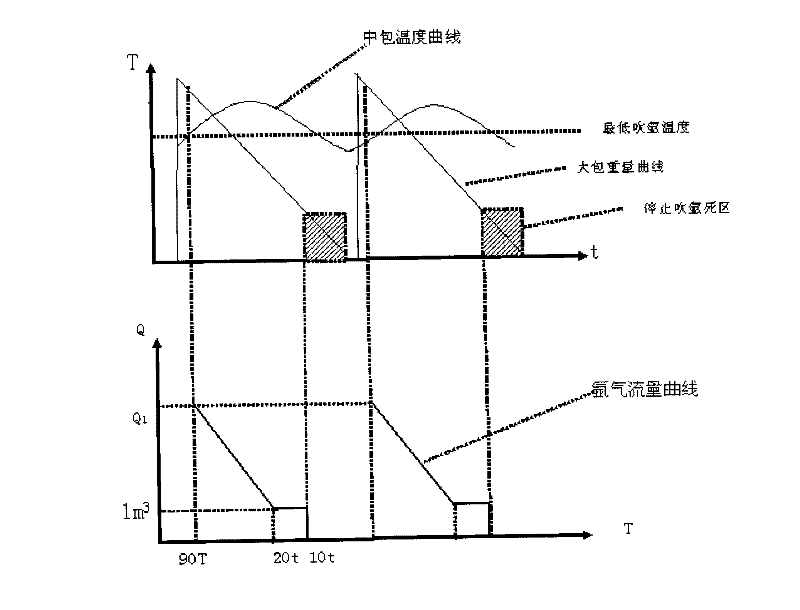

[0016] See figure 2 , Automatic control method of argon blowing in molten steel tank of continuous casting machine. This method controls the amount of argon blowing by designing the argon blowing curve so that the amount of argon gas in the ladle can be effectively adjusted with the weight of molten steel in the ladle, so that the argon blowing effect is the best.

[0017] The argon gas flow Q, the initial set value of the argon gas flow Q1, and the weight T of molten steel in the ladle are calculated according to the following formula:

...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com