Iron-loaded cotton fiber material and preparation method thereof

A cotton fiber, iron-carrying technology, applied in chemical instruments and methods, other chemical processes, alkali metal oxides/hydroxides, etc., to achieve the effects of easy elution and regeneration, mild reaction conditions and stable performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

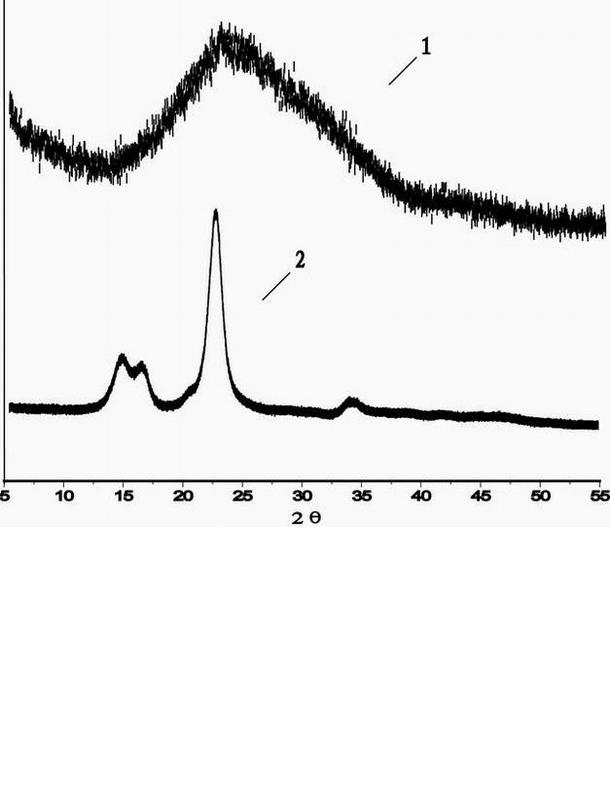

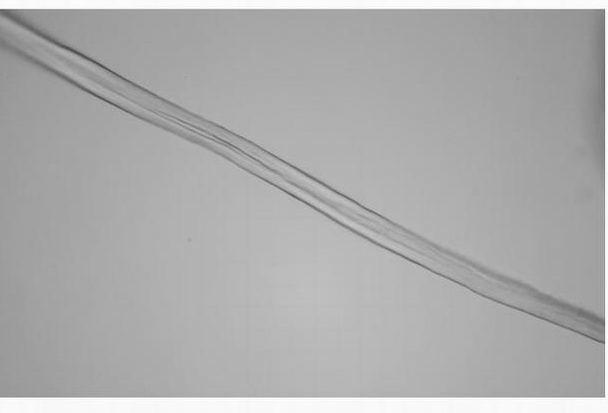

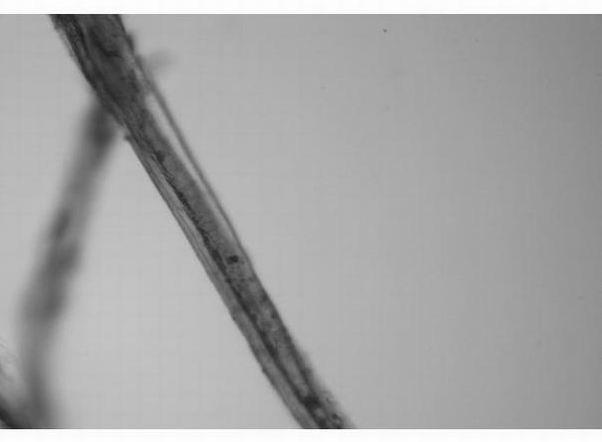

[0017] Submerge 6g of absorbent cotton fibers in 100mL of 5% ferric chloride solution, raise the temperature to 30°C, and after 2 hours, add 105mL of 1M sodium hydroxide solution dropwise with stirring, and the adding speed is controlled at 1ml / min. When the pH value of the solution rose to 4, the addition of sodium hydroxide was stopped, the solution was poured out, and the fiber was washed with water several times, and the above-mentioned addition process of sodium hydroxide was repeated 6 times. After loading the iron, let it stand for 5 hours, then take it out, wash it with water until it is neutral, and dry it in an oven at 45°C. After weighing, the weight of the fiber increases by 27.8%. Its XRD spectrum and micrograph are as attached figure 1 And shown in Figure 2. from figure 1 It can be seen that the iron in the iron-loaded fiber exists in the form of amorphous hydroxide; it can be seen from Figure 2 that after the absorbent cotton is loaded with iron, it still ma...

Embodiment 2

[0019] Immerse 350g of absorbent cotton fibers in 2000mL of 10% ferric sulfate solution, raise the temperature to 25°C, and after 3 hours, add 2050mL of 0.5M sodium hydroxide solution dropwise under stirring, and the adding speed is controlled at 20ml / min. When the pH value of the solution rose to 4, the addition of sodium hydroxide was stopped, the solution was poured out, and the fiber was washed with water several times, and the above-mentioned addition process of sodium hydroxide was repeated 6 times. After loading the iron, let it stand for 5 hours, then take it out, wash it with water until neutral, and dry it in an oven at 60°C. After weighing, the weight of the fiber increases by 16.9%. Its XRD spectrum and micrograph are as embodiment 1.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Length | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

| Adsorption capacity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com