Soldering and mounting method of electric connector

An electrical connector and installation method technology, applied in the direction of connection, circuit/collector parts, circuits, etc., can solve problems such as short circuit easily, and achieve the effect of improving product qualification rate, reducing production cost, and improving welding and installation efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

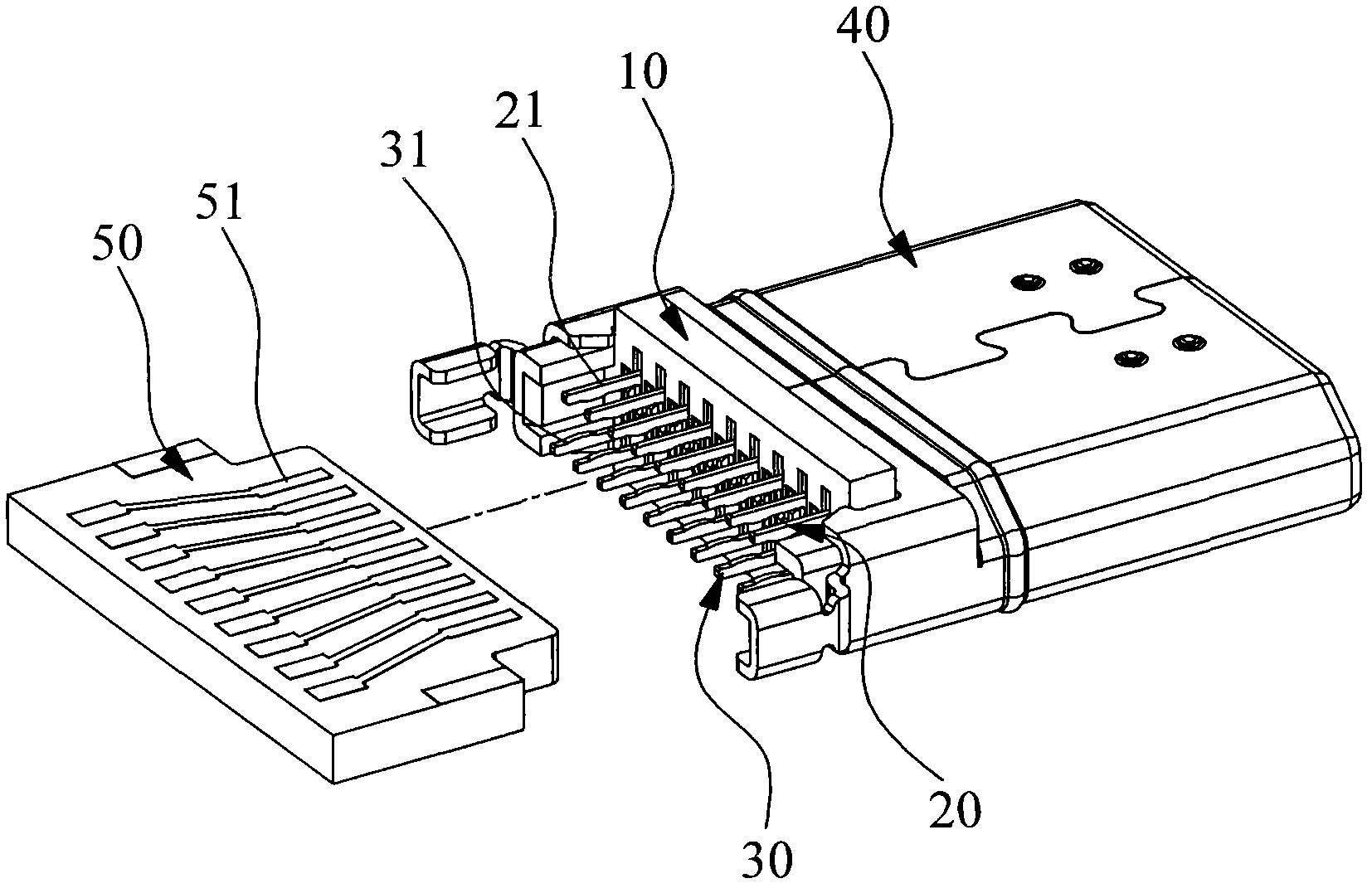

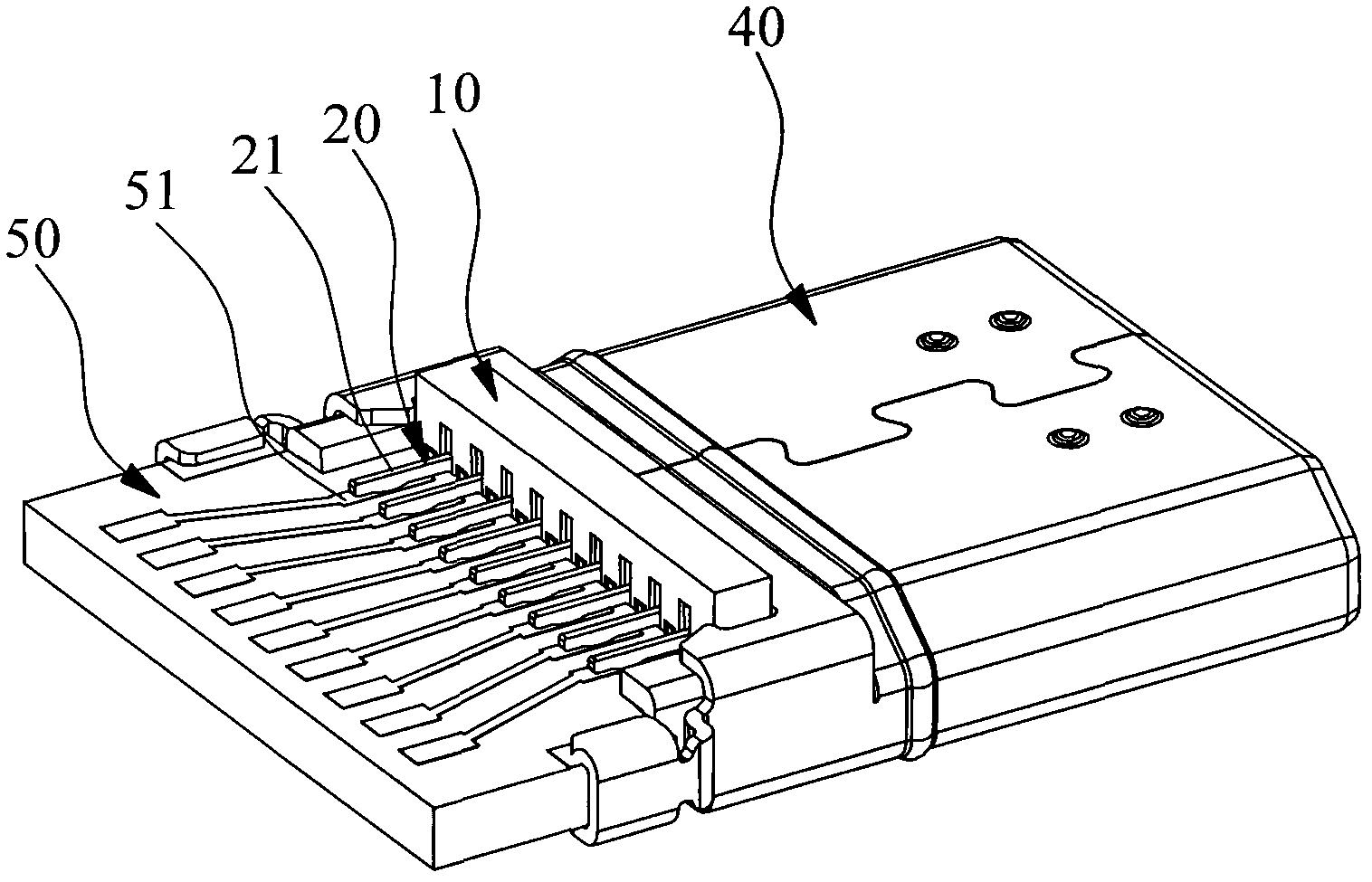

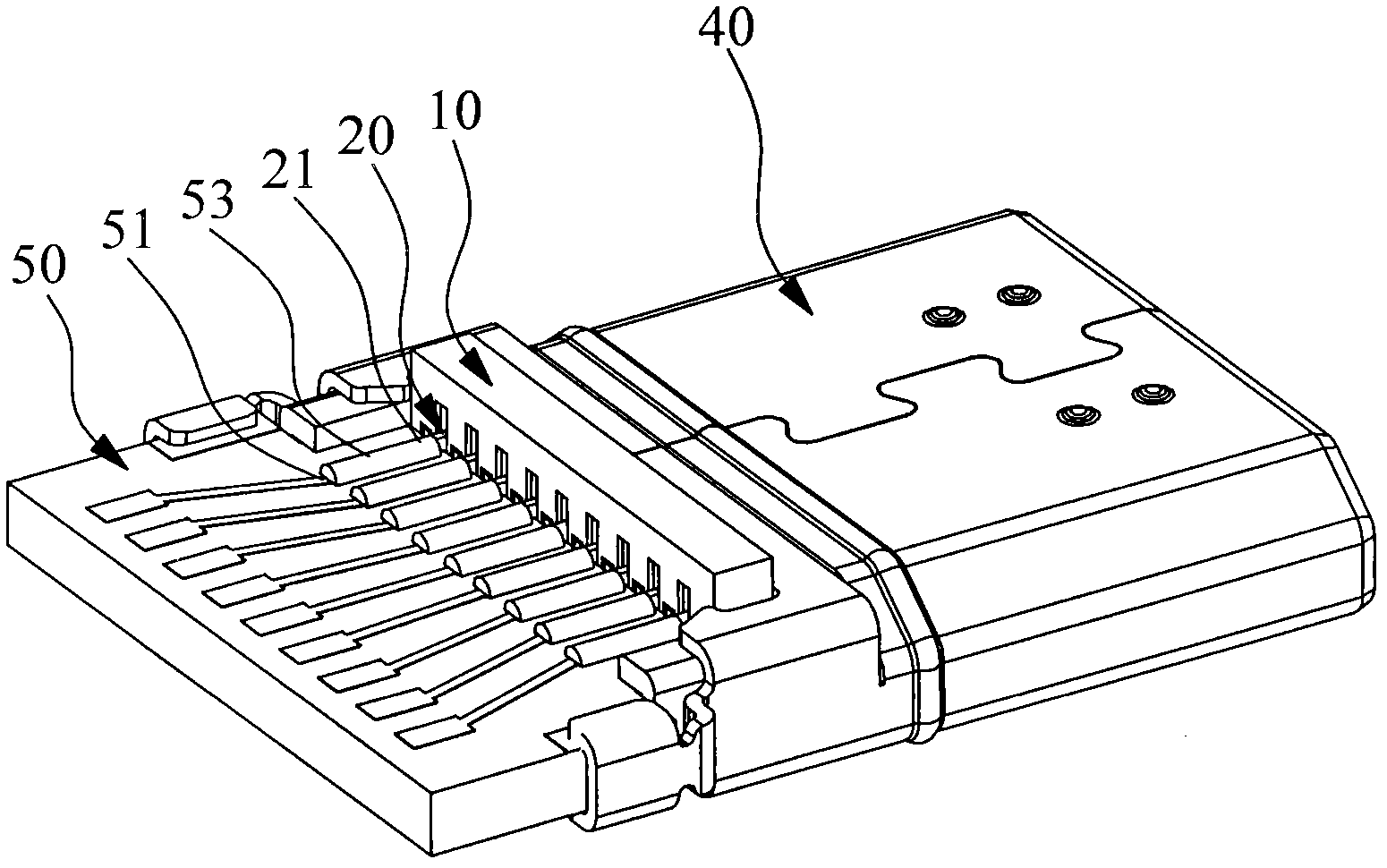

[0032] Please refer to Figure 1 to Figure 6 As shown, it shows the specific structure of the preferred embodiment of the present invention, including an insulating housing 10 , a first conductive terminal 20 , a second conductive terminal 30 , a metal shell 40 and a PCB board 50 .

[0033] Wherein, the first conductive terminal 20 and the second conductive terminal 30 are both disposed on the insulating body 10, and the welding portion 21 of the first conductive terminal 20 and the welding portion 31 of the second conductive terminal 30 both extend out of the insulating body 10, The PIN distance between the first conductive terminal 20 and the second conductive terminal 30 is less than 1.5 mm. The metal shell 40 covers the insulating body 10 , and the metal shell 40 is used to prevent electromagnetic interference.

[0034] The upper surface of the PCB board 50 is provided with a tin-eating area 51, and the lower surface of the PCB board is provided with a tin-eating area 52....

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com