Pilot-operated type water hydraulic pressure digital proportional direction valve

A proportional directional valve and water hydraulic technology, applied in the field of hydraulic control valves, can solve the problems that the proportional directional valve cannot be directly controlled by the computer, the structure of the proportional electromagnet is complex, and the anti-pollution ability is poor, so as to achieve large movable displacement and structural Simple, anti-pollution effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0028] The present invention will be further described below in conjunction with the accompanying drawings and specific embodiments.

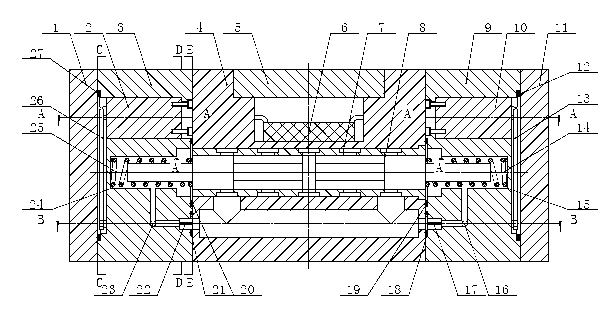

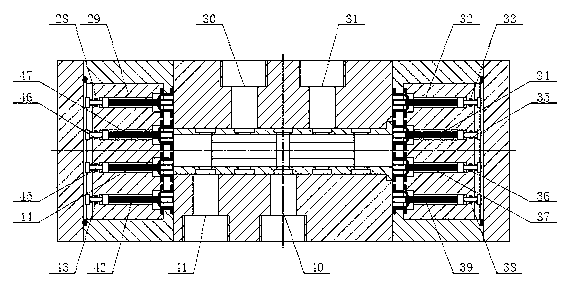

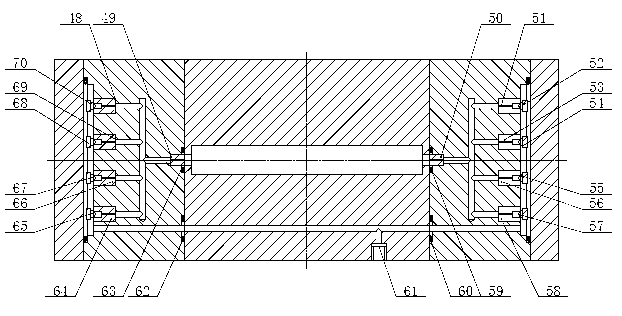

[0029] Figure 1 to Figure 7 It is a structural diagram of the present invention. In the figure: 1-bonnet; 2-encapsulation shell; 3-pilot valve body; 4-main valve body; 5-cover plate; 6-circuit board; 7-main valve sleeve; 8-main valve core ;9-pilot valve body; 10-encapsulation shell; 11-bonnet; 12-O type sealing ring; 13-compliance mechanism; 14-main valve return spring; 15-main valve spring seat; 16-pilot valve control port ;17-damping hole; 18-O-type sealing ring; 19-O-type sealing ring; 20-O-type sealing ring; 21-O-type sealing ring; 22-damping hole; 23-pilot valve control port; 24-main valve Spring seat; 25-main valve return spring; 26-compliance mechanism; 27-O type sealing ring; 28-piston rod assembly; 29-piezoelectric ceramics; 30-three-position four-way valve A port; Valve B port; 32-piezoelectric ceramics; 33-piston rod assembly; 34...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com