Laminated sheet glass curtain wall for regulating cavity vacuum degree for thermal insulation

A flat glass and vacuum technology, applied in the field of building materials, can solve the problems of loss of vacuum, difficulty in adjustment, loss of good performance, etc., and achieve the effect of improving light transmittance and diversifying structural forms

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

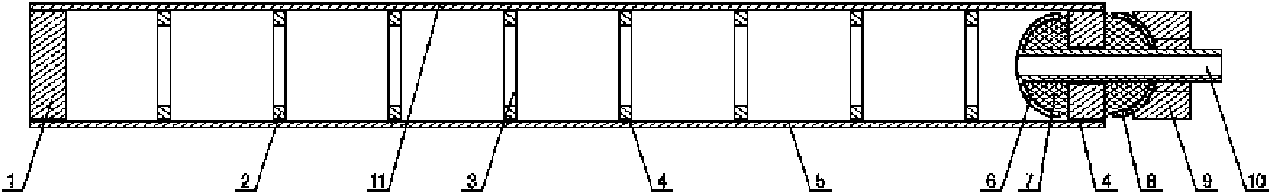

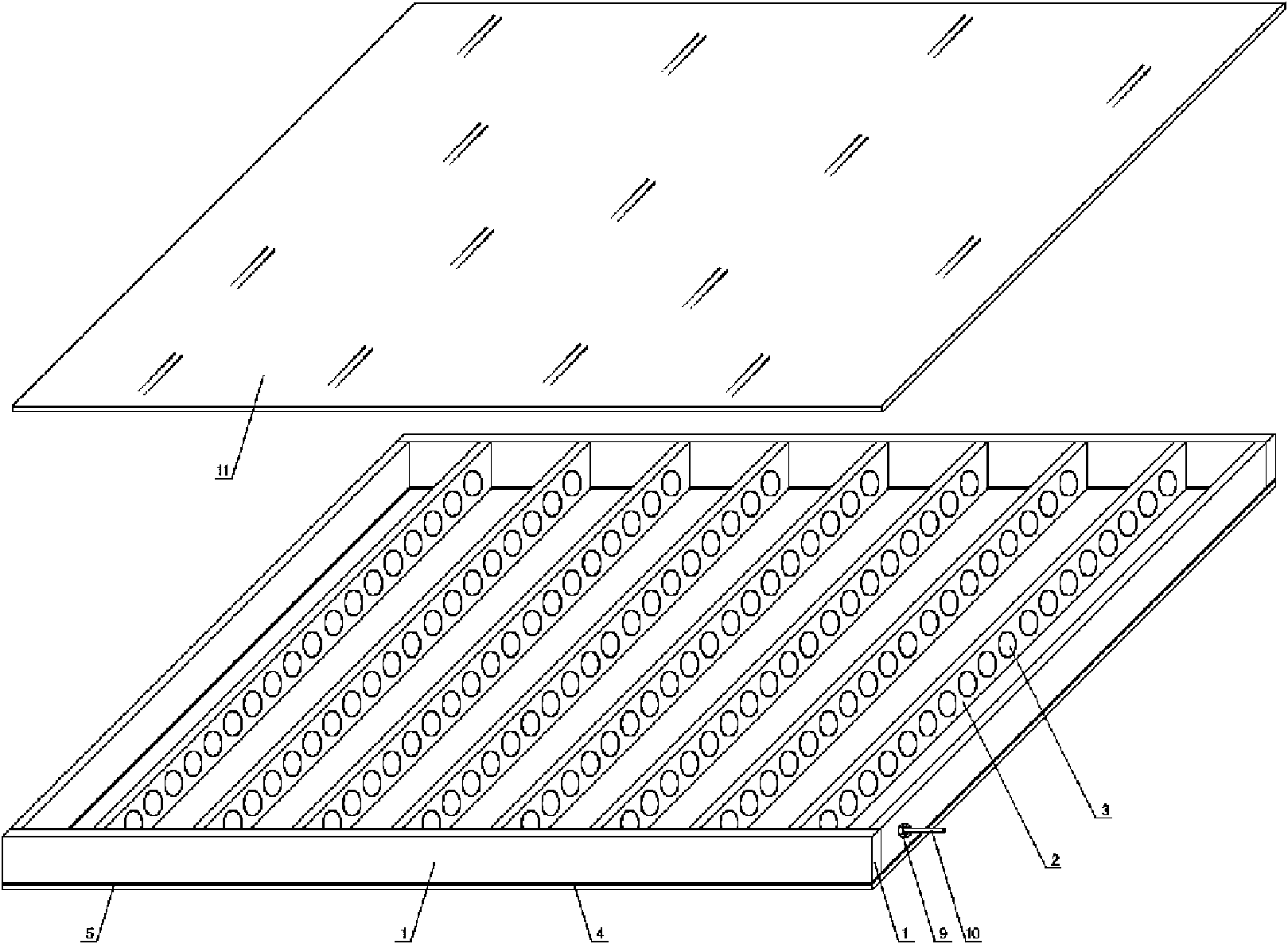

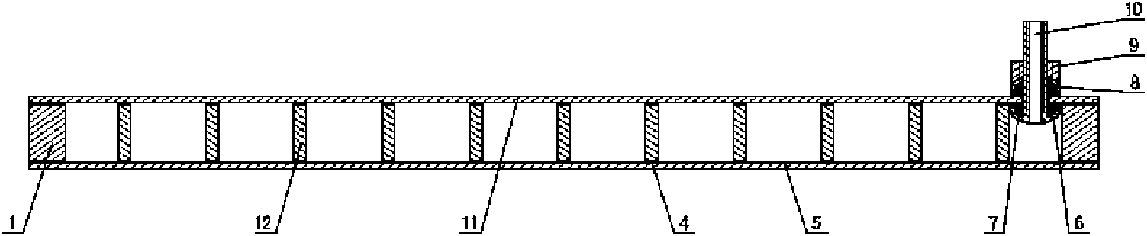

[0037] Such as figure 1 , figure 2 Shown: the laminated flat glass curtain wall for regulating the vacuum degree of the cavity, including the glass shell, the intake and exhaust pipe heads of the cavity, the fastening and sealing pipe fittings and the sealant. The glass shell is composed of a bottom glass plate 5, a front glass plate 11, The support and edge sealing layer 1 is formed by bonding the sealant 4, and the intake and exhaust pipe head 10 is connected to the glass shell, wherein the edge sealing layer 1 is a rectangular glass strip of equal height, and the support is a rectangular glass strip 2 of equal height, Rectangular glass strip 2 is provided with heat insulation opening 3; along the edge of bottom glass plate 5, rectangular glass strip 2 of equal height is vertically sealed and bonded by sealant 4 to form a glass tank with bottom glass plate as the bottom and glass strip as frame , the bottom glass plate surface in the glass tank is vertically bonded with a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com