Preparation method of gas-well water controlling agent

A technology of water control agent and gas well, applied in the direction of chemical instruments and methods, drilling compositions, etc., can solve the problems of poor reservoir physical properties, short water control period, easy to block gas flow channels, etc., and achieve thermal stability and salinity Good stability, small change in gas phase permeability, and easy control of reaction conditions

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

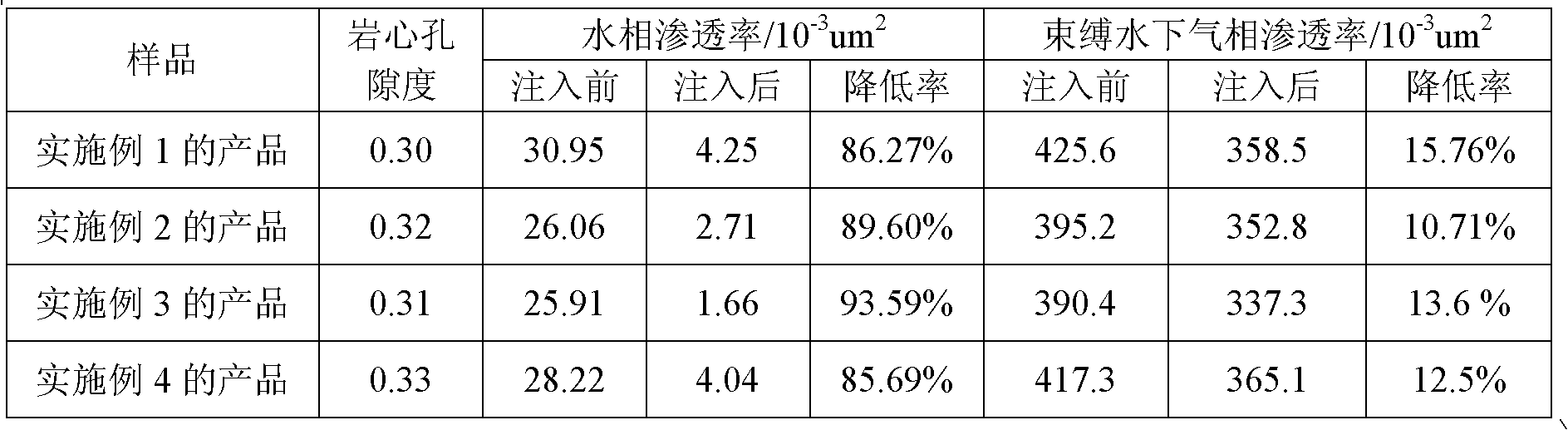

Examples

Embodiment 1

[0028] A gas well water control agent and a preparation method thereof, comprising the steps of:

[0029] a. At room temperature, uniformly mix anionic polyacrylamide (molecular weight: 16 million), cationic polymer and KCl solution with a mass concentration of 2.0% according to the mass ratio of 0.1:0.02:100, and stir slowly until completely dissolved to form a polymer compound solution;

[0030] The cationic polymer is formed by the copolymerization of acryloyloxyethyltrimethylammonium chloride and acrylamide, with a molecular weight of 4 million.

[0031] b. Compound ethyl acetate, sodium bicarbonate and the polymer composite solution formed in step a according to the mass ratio of 0.1:0.5:100 to obtain a gas well water control agent with water control effect.

Embodiment 2

[0033] A gas well water control agent and a preparation method thereof, comprising the steps of:

[0034] a. At room temperature, uniformly mix anionic polyacrylamide (molecular weight: 16 million), cationic polymer and KCl solution with a mass concentration of 2.0% according to the mass ratio of 0.15:0.05:100, and stir slowly until completely dissolved to form a polymer compound solution;

[0035] Described cationic polymer general embodiment 1.

[0036] b. Compound ethyl acetate, sodium bicarbonate and the polymer composite solution formed in step a according to the mass ratio of 0.15:0.8:100 to obtain a gas well water control agent with water control effect.

Embodiment 3

[0038] A gas well water control agent and a preparation method thereof, comprising the steps of:

[0039] a. At room temperature, uniformly mix anionic polyacrylamide (molecular weight: 16 million), cationic polymer, and NaCl solution (co-solvent) with a mass concentration of 2.0% according to the mass ratio of 0.2:0.08:100, and stir slowly until complete Dissolve to form a polymer composite solution;

[0040] The cationic polymer is formed by the copolymerization of acryloyloxyethyltrimethylammonium chloride and acrylamide, with a molecular weight of 4 million.

[0041] b. Compound ethyl lactate, sodium bicarbonate and the polymer composite solution formed in step a according to the mass ratio of 0.2:0.8:100 to obtain a gas well water control agent with water control effect.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com