Water-saving antifreezing device

A technology for antifreeze and water supply valves, applied to valve details, sliding valves, engine components, etc., can solve the problems of water outlet pipes that cannot be discharged, the impact of the surrounding environment, and waste of water resources, etc., to achieve simple manufacturing and processing, reduce product costs, The effect of convenient maintenance and debugging

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

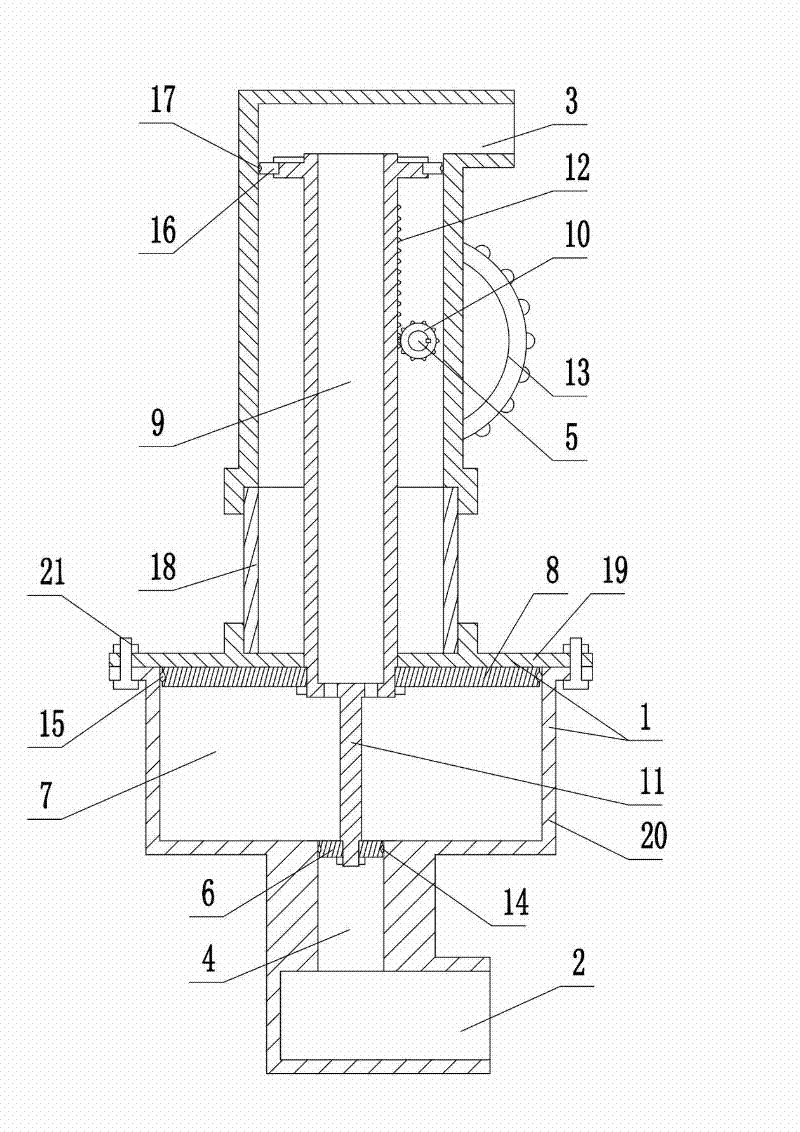

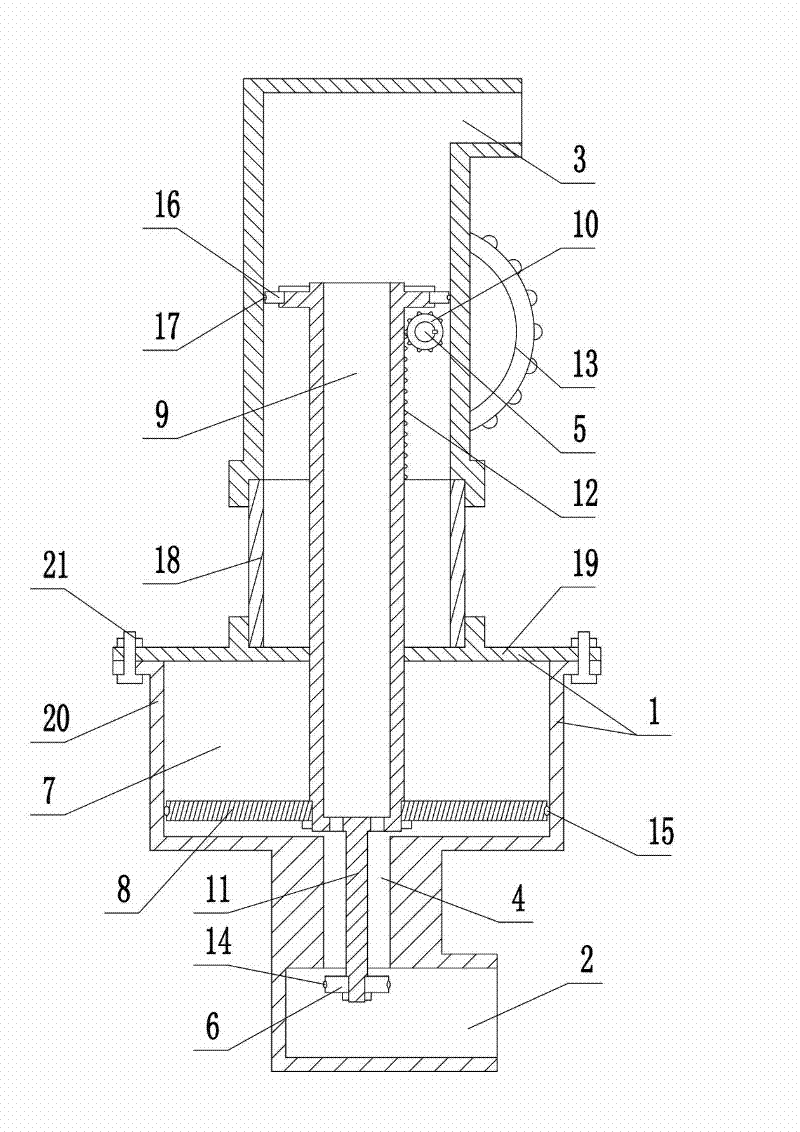

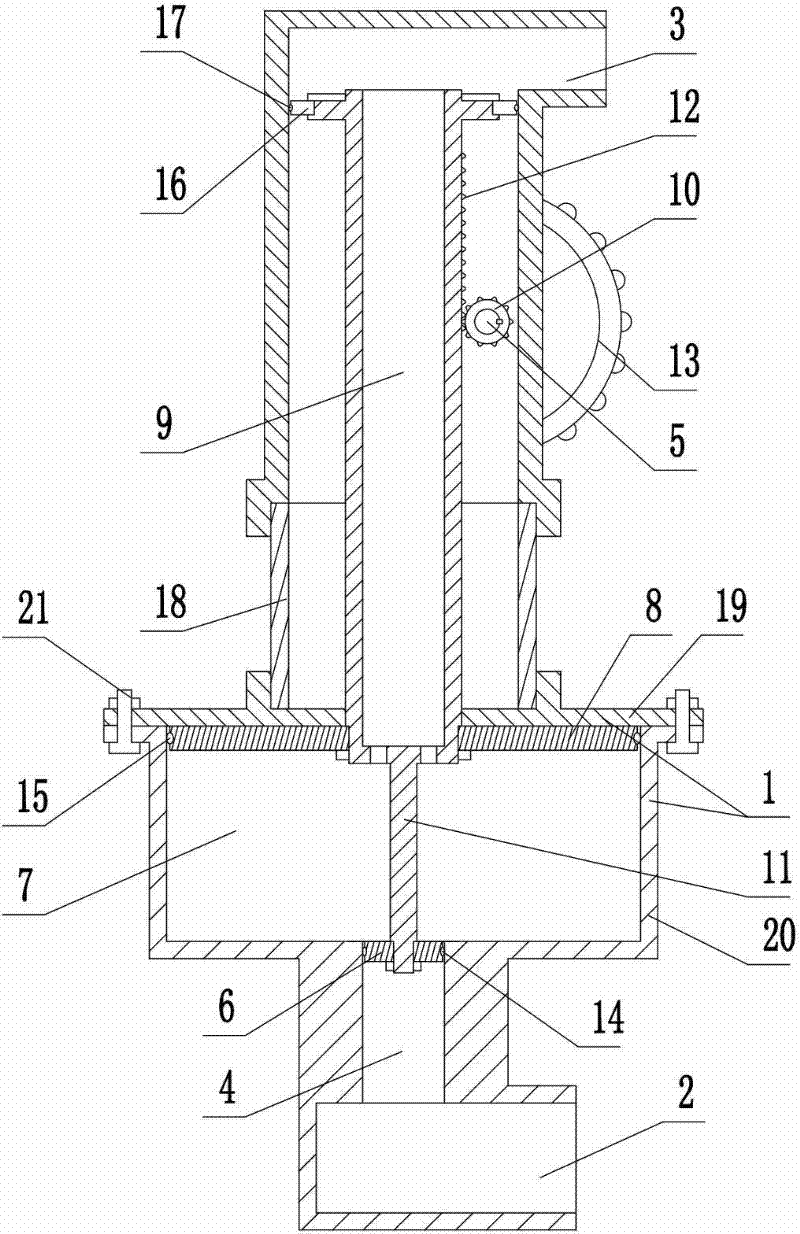

[0029] Such as figure 1 As shown, the water-saving antifreeze device includes a valve body 1, the lower part of the valve body 1 is fixedly connected with a water inlet pipe 2 communicating with the inner cavity of the valve body 1, and the water inlet pipe 2 is a round pipe and is arranged horizontally. The upper part of the valve body 1 is fixedly connected with a water outlet pipe 3 communicating with the inner cavity of the valve body 1, and the water outlet pipe 3 is also a round pipe and is arranged horizontally. A water supply valve seat 4 is arranged in the inner cavity of the valve body 1. The water supply valve seat 4 is a circular tubular cavity. The axis of the water supply valve seat 4 is vertically arranged. The water supply valve seat 4 is provided with a water supply valve plug 6 , which is in the shape of a disc, and the outer periphery of the water supply valve plug 6 is vertically slidingly matched with the inner wall of the water supply valve seat 4 . The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com