Method for producing alcohol by taking anaerobic effluent as ingredient water

An anaerobic effluent and alcohol technology, applied in chemical instruments and methods, water/sewage multi-stage treatment, water/sludge/sewage treatment, etc., can solve the problem that the process cannot run stably for a long time, is not conducive to the subsequent utilization of biogas, and increases alcohol Production cost and other issues, to achieve the effect of reducing nitrogen content, reducing hydrogen sulfide concentration, and eliminating inhibition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

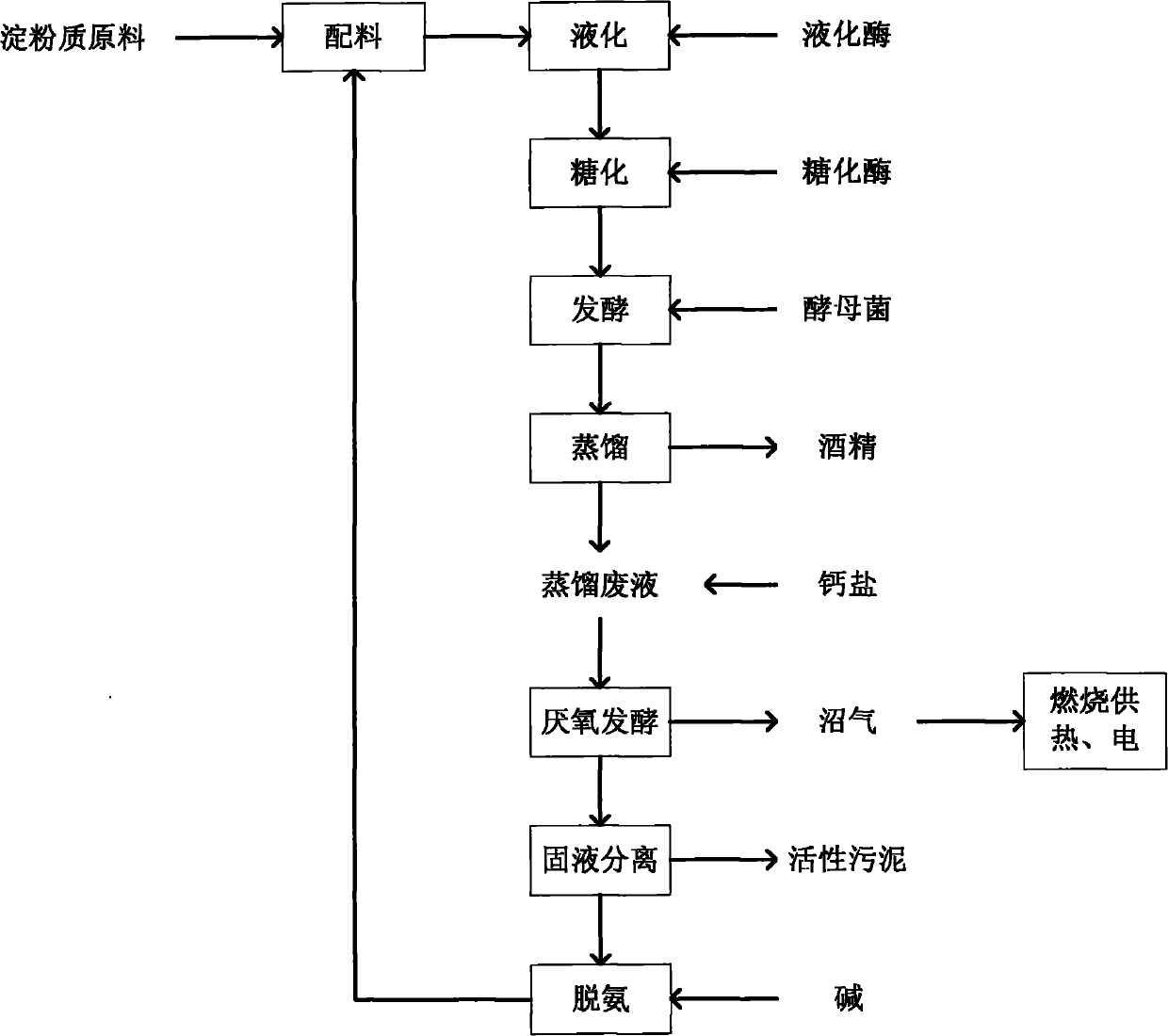

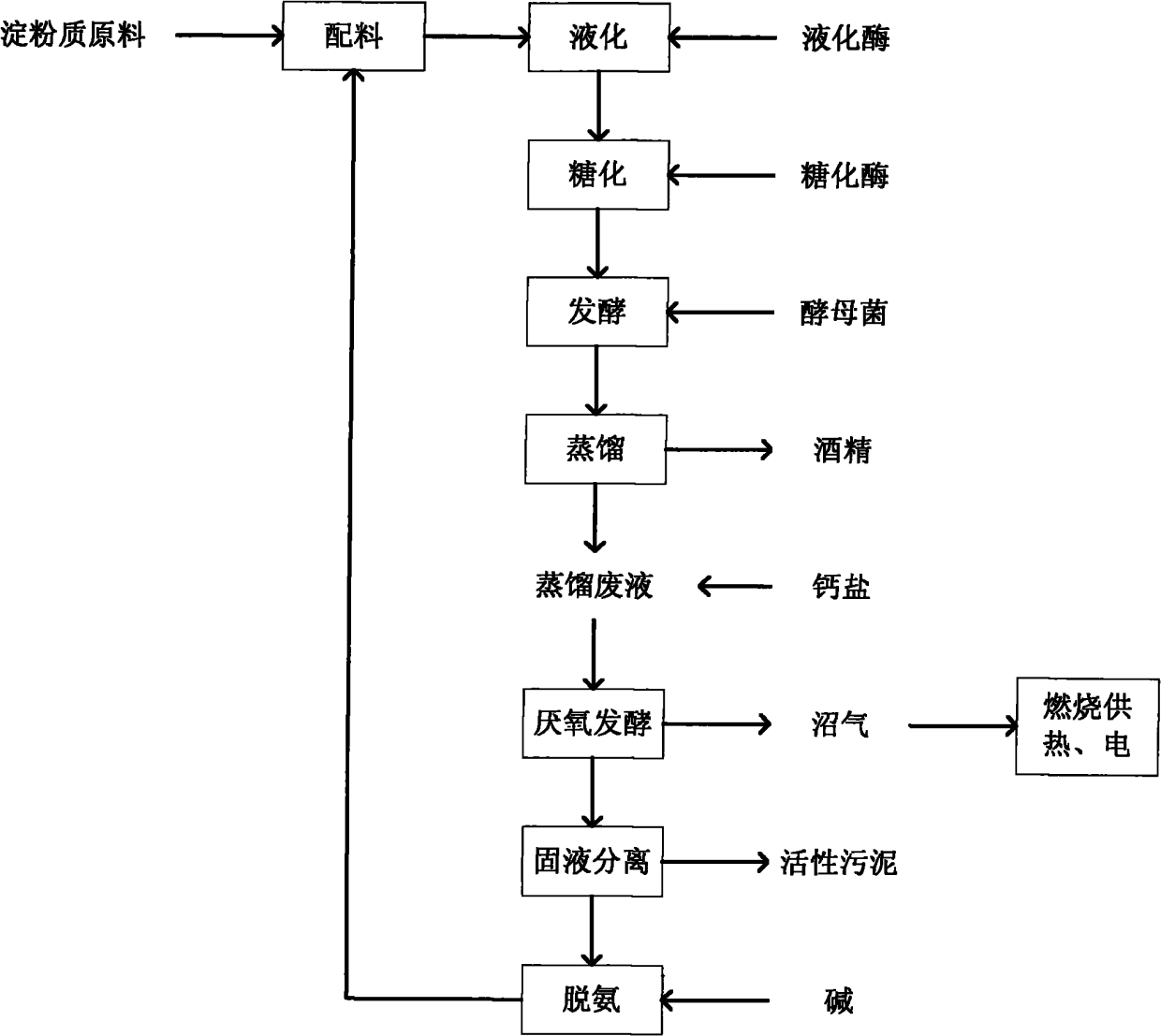

Method used

Image

Examples

Embodiment 1

[0035] Example 1: A method for improving the stability of an alcohol production process using anaerobic effluent as the batching water adopts the following process steps:

[0036] 1. Take 100g of cassava flour and add 200g of the last batch of anaerobic effluent treated in step 8 for ingredients;

[0037] 2. Adjust the pH of the material liquid obtained in step 1 to 6.0 with 30% (w / w) sulfuric acid, add 800u high temperature resistant α-amylase, and cook at 100°C for 30 minutes to liquefy the starch;

[0038] 3. After the liquefaction is finished, cool the liquefied mash to 60°C, then adjust the pH of the material liquid to 4.0 with 30% (w / w) sulfuric acid, and then add 12000u saccharification enzyme for saccharification for 30 minutes;

[0039] 4. The material liquid obtained in step 3 is further cooled to 30°C, 15% of the volume of the material liquid is inserted into the cultured Saccharomyces cerevisiae seed liquid, and fermentation is carried out at a fermentation temperature of 3...

Embodiment 2

[0045] Example 2: A method for improving the stability of an alcohol production process using anaerobic effluent as the batching water, using the following process steps:

[0046] 1. Take 100g of cassava flour and add 300g of the last batch of anaerobic effluent treated in step 8 for ingredients;

[0047] 2. Adjust the pH of the material liquid obtained in step 1 with 30% (w / w) sulfuric acid to 6.0, add 1000u high temperature resistant α-amylase, and cook at 100°C for 30 minutes to liquefy the starch;

[0048] 3. After the liquefaction is completed, cool the liquefied mash to 60°C, then adjust the pH of the material liquid to 5.0 with 30% (w / w) sulfuric acid, and then add 13000u saccharification enzyme for saccharification for 15 minutes;

[0049] 4. The material liquid obtained in step 3 is further cooled to 30°C, and 8% of the volume of the material liquid is inserted into the cultured Saccharomyces cerevisiae seed liquid for fermentation, the fermentation temperature is 30°C, and th...

Embodiment 3

[0055] Example 3: A method for improving the stability of an alcohol production process using anaerobic effluent as the batching water, using the following process steps:

[0056] 1. Take 100g of cassava flour and add 250g of the last batch of anaerobic effluent treated in step 8 for ingredients;

[0057] 2. Adjust the pH of the material liquid obtained in step 1 to 6.0 with 30% (w / w) sulfuric acid, add 800u high temperature resistant α-amylase, and cook at 100°C for 30 minutes to liquefy the starch;

[0058] 3. After the liquefaction is over, cool the liquefied mash to 60°C, then adjust the pH of the material liquid to 5.0 with 30% (w / w) sulfuric acid, and then add 12000u glucoamylase for saccharification for 60 minutes;

[0059] 4. The material liquid obtained in step 3 is further cooled to 28°C, 0.2g of active dry yeast is added, and fermentation is carried out. The fermentation temperature is 28°C and the fermentation time is 60 hours;

[0060] 5. Distill the completely fermented fe...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com