Preparation method of polyamide/styrene comb-shaped graft polymer

A graft polymer, styrene technology, applied in the field of preparation of polyamide/styrene comb graft polymers, can solve the problems of high cost, difficult to avoid defects, complicated methods, etc., and achieves process controllability and expansion. The effect of simple use and production process

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

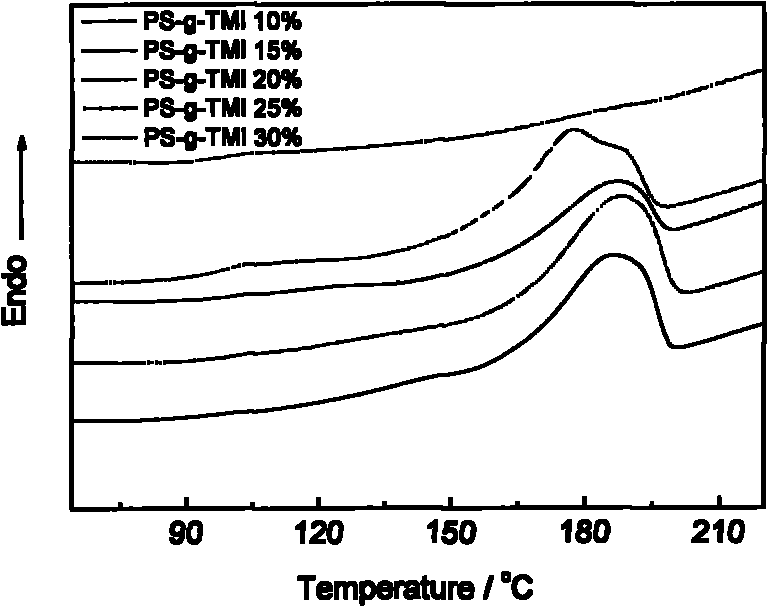

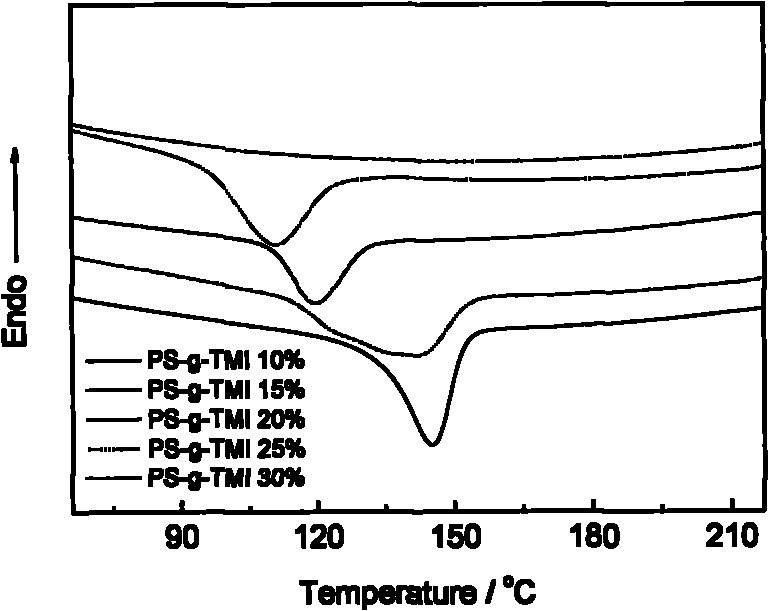

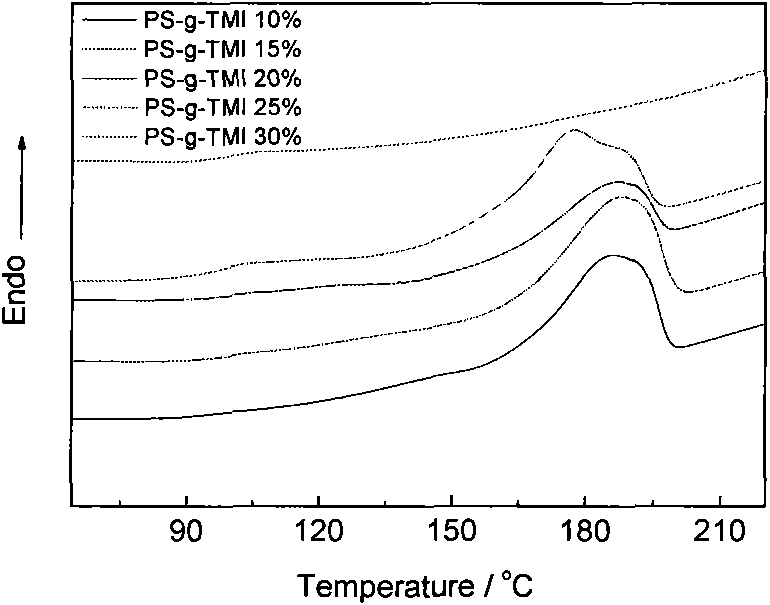

[0024] Add 220ml of styrene (St) and 8ml of 3-isopropenyl-a, a'-dimethylbenzyl isocyanate (TMI) into 100ml of toluene solvent. With magnetic stirring, the temperature was raised to 80° C. under the protection of nitrogen, and then 0.8 g (accounting for about 4 wt % of the total weight of styrene and TMI) of AIBN was added to react at constant temperature for 24 hours. The resulting product was precipitated with methanol, dissolved in tetrahydrofuran, and repeated four times to completely remove small molecules. Finally, vacuum drying at 100° C. for 24 h yielded a white solid of copolymer P(St-co-TMI).

[0025] Take 100g of P(St-co-TMI) and add it to 900g of caprolactam / laurolactam (monomer molar ratio: 1:1) mixed monomer, heat to 180°C and stir until fully dissolved, at this time the solution is transparent. Then add 4wt% of sodium caprolactam (based on the total weight of the system), shake quickly and leave to react for 30 minutes to obtain a comb polymer. The mechanical p...

Embodiment 2

[0027] Add 220ml of styrene (St) and 8ml of 3-isopropenyl-a, a'-dimethylbenzyl isocyanate (TMI) into 100ml of toluene solvent. With magnetic stirring, the temperature was raised to 80° C. under the protection of nitrogen, and then 0.8 g (accounting for about 4 wt % of the total weight of styrene and TMI) of AIBN was added to react at constant temperature for 24 hours. The resulting product was precipitated with methanol, dissolved in tetrahydrofuran, and repeated four times to completely remove small molecules. Finally, vacuum drying at 100° C. for 24 h yielded a white solid of copolymer P(St-co-TMI).

[0028] Take 150g of P(St-co-TMI) and add it to 850g of caprolactam / laurolactam (monomer molar ratio: 1:1) mixed monomer, heat to 180°C and stir until fully dissolved, at this time the solution is transparent. Then add 4wt% of sodium caprolactam (based on the total weight of the system), shake quickly and leave to react for 30 minutes to obtain a comb polymer. The mechanical p...

Embodiment 3

[0030] Add 220ml of styrene (St) and 8ml of 3-isopropenyl-a, a'-dimethylbenzyl isocyanate (TMI) into 100ml of toluene solvent. With magnetic stirring, the temperature was raised to 80° C. under the protection of nitrogen, and then 0.8 g (accounting for about 4 wt % of the total weight of styrene and TMI) of AIBN was added to react at constant temperature for 24 hours. The resulting product was precipitated with methanol, dissolved in tetrahydrofuran, and repeated four times to completely remove small molecules. Finally, vacuum drying at 100° C. for 24 h yielded a white solid of copolymer P(St-co-TMI).

[0031] Take 200g of P(St-co-TMI) and add it to 800g of caprolactam / laurolactam (monomer molar ratio: 1:1) mixed monomer, heat to 180°C and stir until fully dissolved, at this time the solution is transparent. Then add 4wt% of sodium caprolactam (based on the total weight of the system), shake quickly and leave to react for 30 minutes to obtain a comb polymer. The mechanical p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com