Device and method for treating low C/N ratio nitrified wastewater

A sewage treatment method and technology for sewage treatment devices, which are applied in the fields of water/sewage multi-stage treatment, water/sludge/sewage treatment, chemical instruments and methods, etc., can solve the problems of unstable nitrification effect and long nitrification start-up time, etc. Achieve significant energy-saving effect, good effluent quality, and low operating cost.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

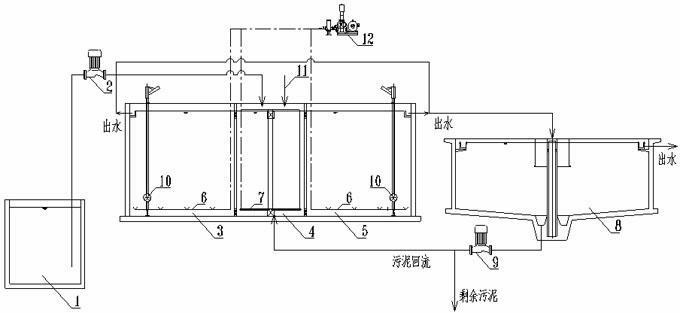

[0029] The 2300t / d high-concentration nitrogen-containing wastewater from a bioengineering company enters the regulating tank first, and then enters the aerobic tank through the sewage lifting pump. The compressed air generated by the blower aerates the sewage through the liftable aeration pipe, and the air volume of the blower is adjusted to control The dissolved oxygen is at 2.0mg / L; the return sludge in the secondary sedimentation tank enters the aerobic tank synchronously; a steam pipe is installed at the water inlet of the aerobic tank to heat the sewage, and the water temperature is controlled at 35°C and pH=8.5. Nitrosation reaction; the sewage enters the first hypoxic tank and the second hypoxic tank through the outlet at the bottom of the aerobic tank. Perforated tube aeration is arranged in the two hypoxic tanks for intermittent aeration, and a submersible mixer is set up for stirring, so as to control The dissolved oxygen is 1.0 mg / L, and the volume ratio of the aero...

Embodiment 2

[0037] A pharmaceutical high-concentration nitrogen-containing wastewater first enters the regulating tank, and then enters the aerobic tank through the sewage lifting pump. The compressed air generated by the blower aerates the sewage through the lifting aeration pipe, and the air volume of the blower is adjusted to control the dissolved oxygen at 1.0mg / L ; The return sludge in the secondary sedimentation tank enters the aerobic tank synchronously; a steam pipe is installed at the water inlet of the aerobic tank to heat the sewage, and the water temperature is controlled at 28°C and pH=7.6 to carry out nitrosation reaction; the sewage passes through well The water outlet at the bottom of the oxygen tank enters the first hypoxic tank and the second hypoxic tank. Perforated tube aeration is arranged in the two hypoxic tanks for intermittent aeration, and a submersible mixer is set up for stirring to control the dissolved oxygen to 0.8mg / L , the volume ratio of the aerobic tank t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com