Industrial dedusting device

A dust removal device, industrial technology, applied in the direction of electromechanical devices, mechanical energy control, electrical components, etc., can solve the problems of power grid impact, brush wear, single-stage wind blade negative pressure capacity, etc., to achieve stable control, reduce maintenance, eliminate impact effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

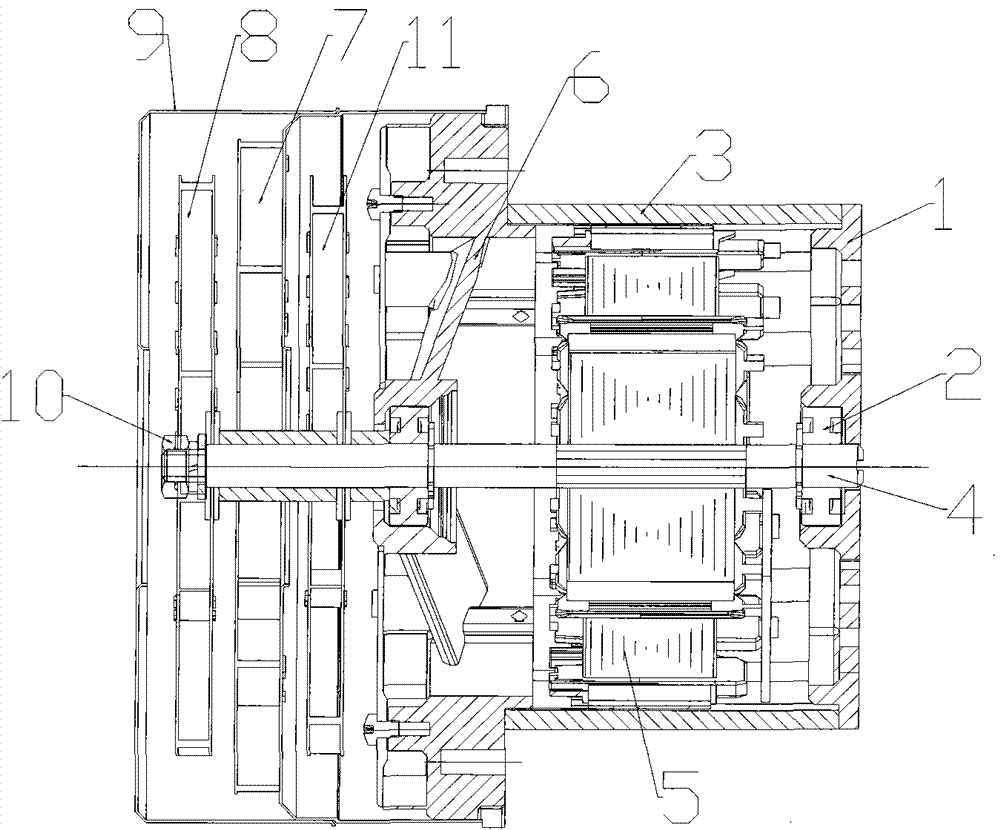

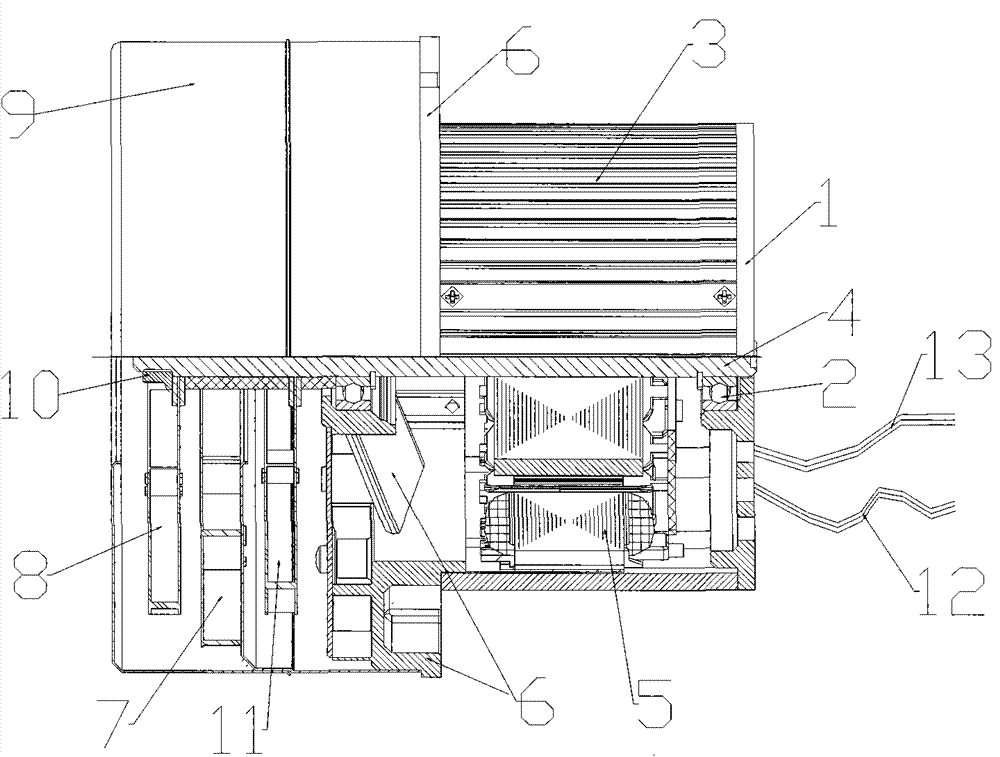

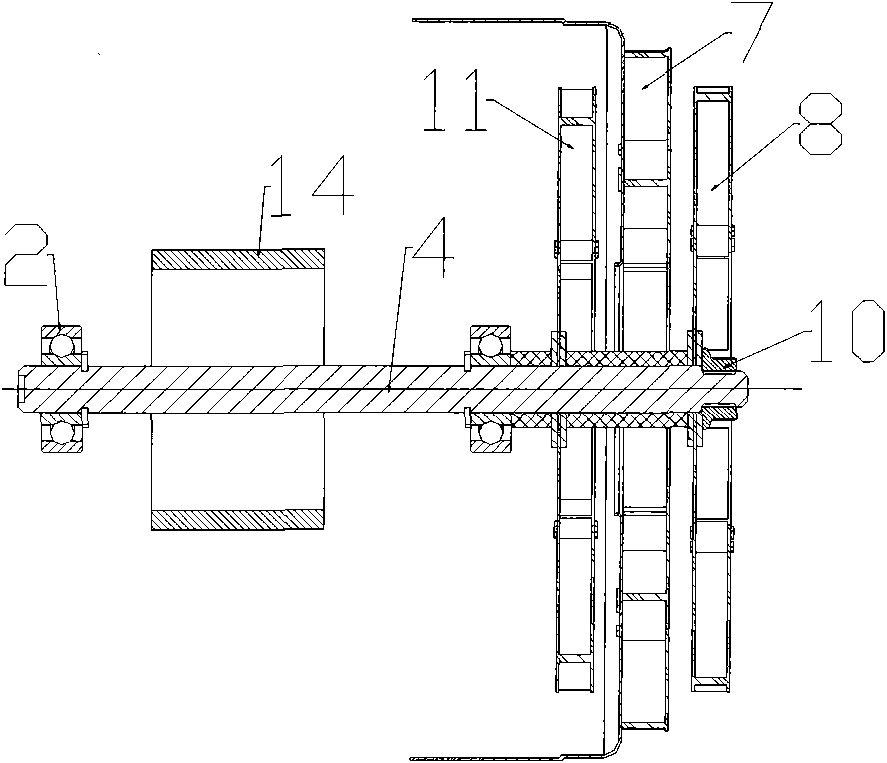

[0020] The industrial dust removal device of the present invention will be described in further detail below with reference to the accompanying drawings.

[0021] The industrial dust removal device of the present invention includes a garbage collection bucket, a bucket cover, a suction pipe and a fan device. The fan device includes a mechanical part and a circuit part. The fan device is installed on the bucket cover, and the fan device includes a fan blade cover 9, a motor, and a front end cover 6. , the casing 3 and the rear end cover 1, the motor drives the fan blade assembly to rotate, the fan blade cover 9 is fixed on the front end cover 6, the inner cavity of the fan blade cover 9 constitutes the fan blade cavity, and the rear end cover 1 is fixed on the front end through the casing 3 The cover 6 forms a motor cavity, the motor is installed in the motor cavity, the fan blade assembly is installed in the fan blade cavity, the motor is a permanent magnet synchronous motor or...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com