Method for improving B acid content of ZSM-5 molecular sieve and realizing yield increase of light olefin

A technology of ZSM-5 and molecular sieve, which is applied in molecular sieve catalysts, chemical instruments and methods, hydrocarbon cracking and hydrocarbon production, etc., can solve the problem of low activity, achieve the effect of simple steps, improve overall reactivity, and increase yield

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0053] Take by weighing 29.1 grams of dried HZSM-5 molecular sieves (silicon-aluminum ratio 30-40), measure its water absorption; weigh Fe(NO 3 ) 3 .9H 2 O 3.31 g, Ti(SO 4 ) 2 2.35 grams, dissolved in an appropriate volume of distilled water to prepare a ferric nitrate / titanium sulfate mixed impregnation solution, slowly pour the mixed impregnation solution into the dried HZSM-5 molecular sieve, and keep stirring to achieve equal volume impregnation; stand for 12 hours Then put it into an oven at 120°C for 6 hours and bake it in a muffle furnace at 540°C for 4 hours to obtain the modified molecular sieve Fe-Ti / ZSM-5.

[0054] The ZSM-5 before modification and the Fe-Ti / ZSM-5 after modification were tabletted, ground and sieved to obtain catalysts ZSM-5 and Fe-Ti / ZSM-5 with spherical particles respectively.

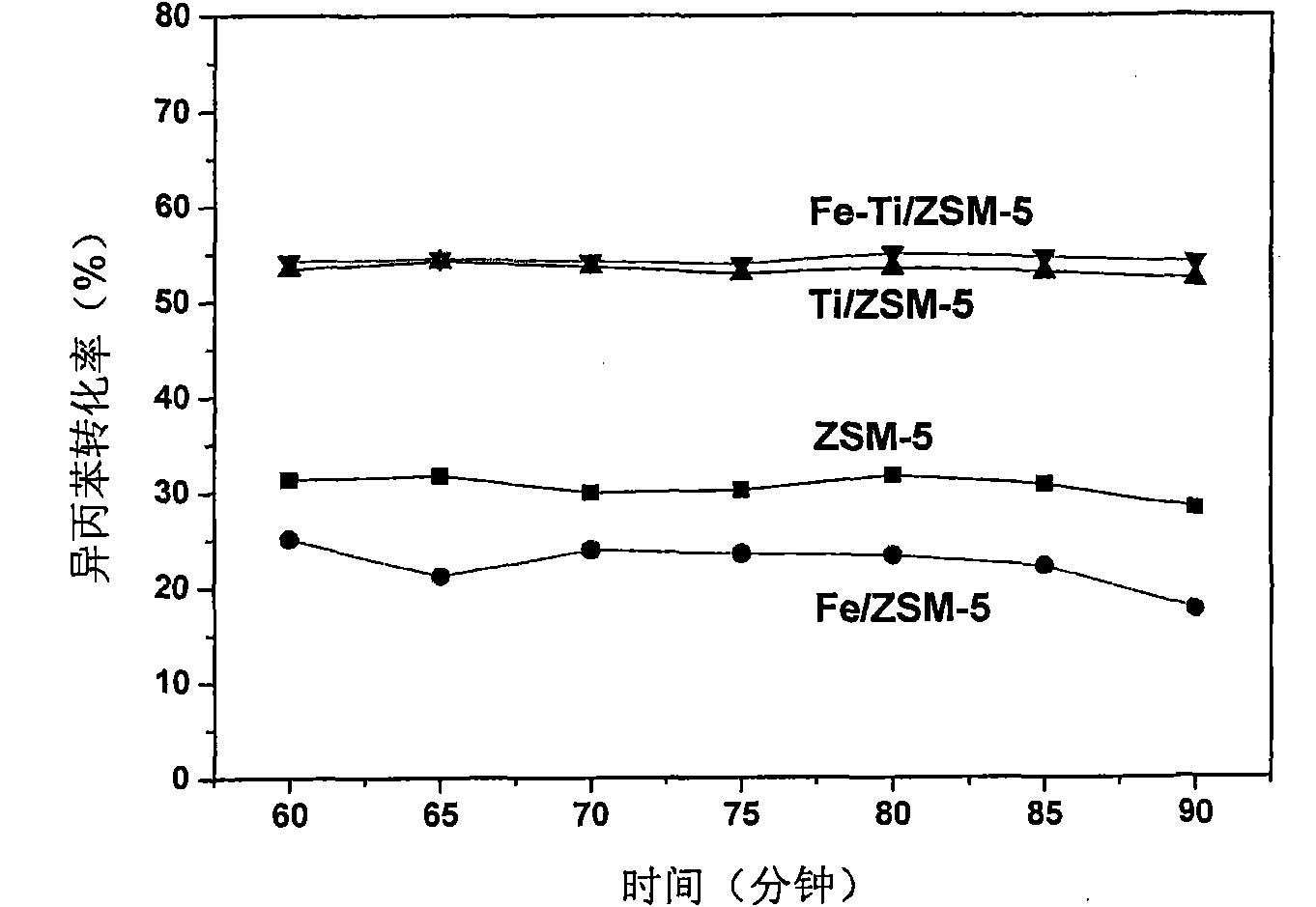

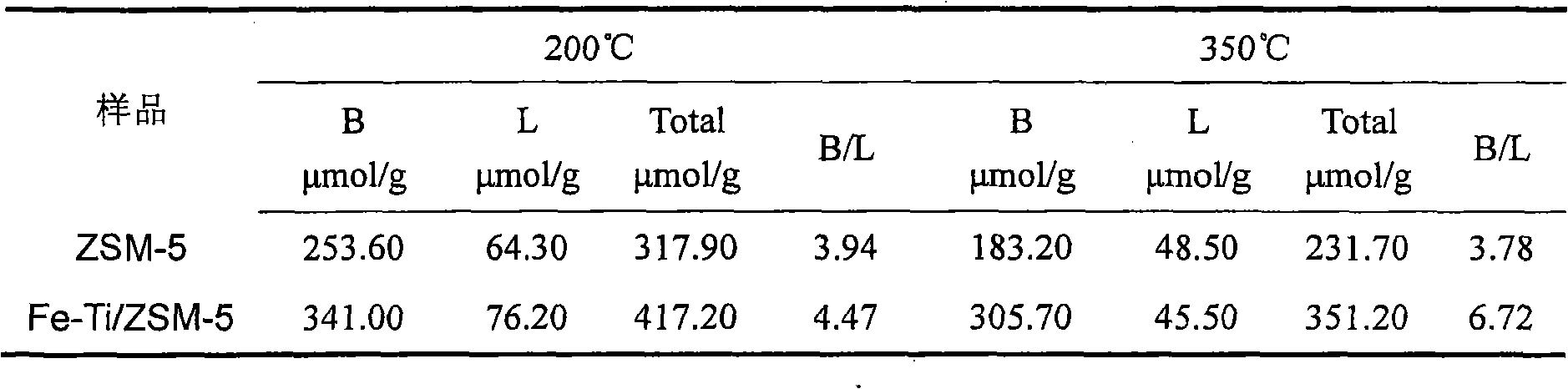

[0055] The above-mentioned ZSM-5 and Fe-Ti / ZSM-5 catalysts were used to determine the amount of acid by pyridine adsorption-desorption infrared spectroscopy, and the ...

Embodiment 2

[0057] Take by weighing two parts of dried HZSM-5 molecular sieves 29.1 grams (silicon-aluminum ratio 30-40) respectively, measure its water absorption; Weigh Fe(NO 3 ) 3 .9H 2 O 3.31 g, Ti(SO 4 ) 2 2.35 grams were respectively dissolved in an appropriate volume of distilled water to prepare ferric nitrate and titanium sulfate impregnating solutions, and the impregnating solutions were slowly poured into the above-mentioned dried HZSM-5 molecular sieves, stirring continuously to realize equal volume impregnation; After standing for 12 hours, put it into an oven at 120°C for 6 hours and bake it in a muffle furnace at 540°C for 4 hours to obtain modified molecular sieves Fe / ZSM-5 and Ti / ZSM-5.

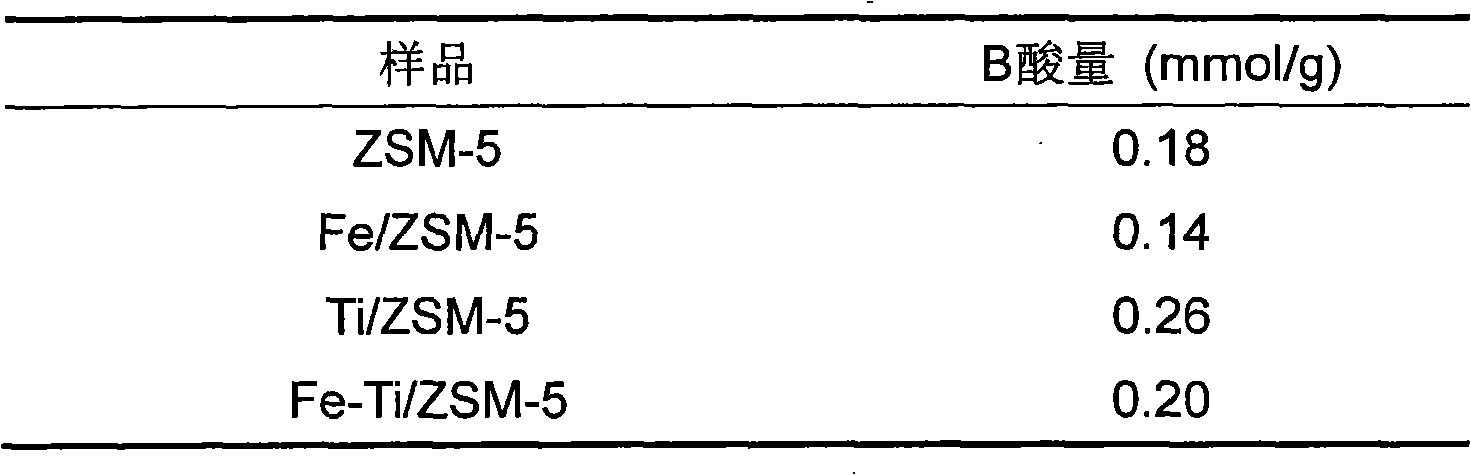

[0058] Prepare catalyst Fe / ZSM-5 and Ti / ZSM-5 according to the method for embodiment 1, and adopt n-propylamine temperature-programmed decomposition method to measure wherein B acid content, the results are shown in Table 2.

[0059] Table 1 Comparison of acidity between ZSM-5 and F...

Embodiment 3

[0064] Take the dried HZSM-5 molecular sieve (silicon-aluminum ratio is 29.7 grams, measure its water absorption; weigh Fe(NO 3 ) 3 .9H 2 O 0.66 g, Ti(SO 4 ) 2 4.23 grams, dissolved in an appropriate volume of distilled water to prepare a ferric nitrate / titanium sulfate mixed impregnation solution, and slowly pour the mixed impregnation solution into the dried HZSM-5 molecular sieve, stirring constantly, and impregnating with equal volume; After 12 hours, put into 120 DEG C of oven and dry for 6 hours; Roast in 540 DEG C of muffle furnaces for 4 hours, obtain the catalyst Fe-Ti / ZSM-5 (Fe / Ti mass ratio of spherical particle by tableting, grinding, sieving then =0.11), after being diluted with 60% quartz sand, the catalyst Fe-Ti / ZSM-5-A1 was obtained. The catalyst was evaluated using n-decene as raw material, and the results are shown in Table 3.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com