Method for separating solid-liquid molecules of pasty material

A molecular separation and material technology, which is applied in the direction of drying solid materials, drying solid materials without heating, lighting and heating equipment, etc., can solve the problems of long drying cycle, high energy consumption of heating and separation, doping of impurities, etc., and achieve heating time Short, short process time, high vacuum effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0015] The specific embodiments of the present invention will be described in detail below in conjunction with the technical solutions and accompanying drawings.

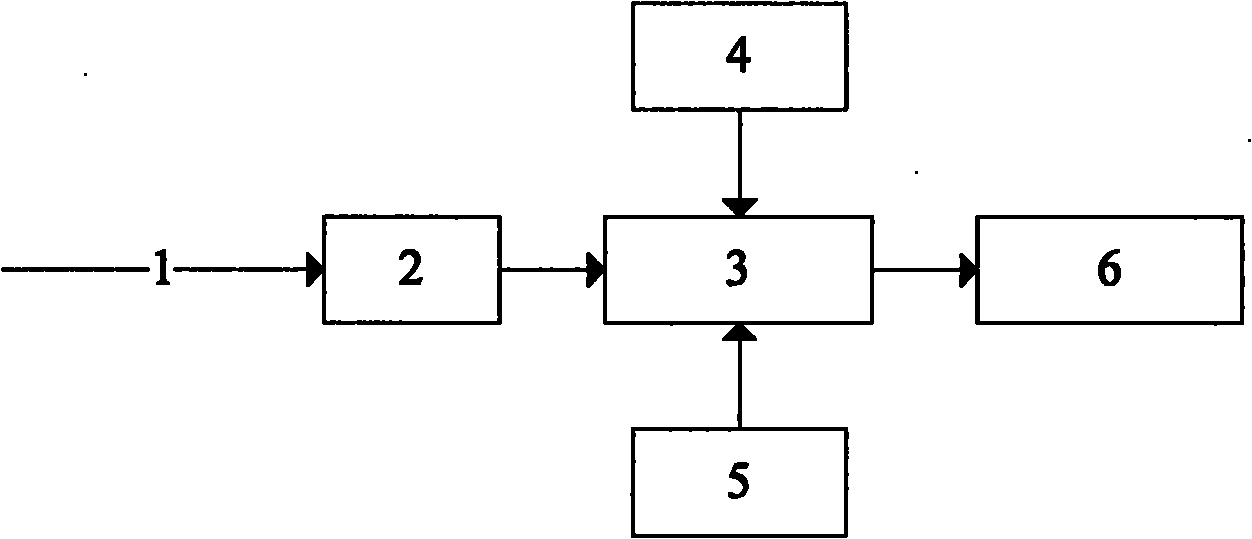

[0016] The pasty material 1 forms a thin film with a thickness of 1mm after passing through the cloth film 2, and a liquid film on the surface of the solid-liquid is formed 3 by applying a certain pressure. After the liquid film is formed 3, the temperature of the whole system is lowered and the vacuum is pumped 4 to increase the mean free path of the liquid molecules, and the liquid molecules are collected through the collection surface 5. The trapped liquid molecules exit the system through the liquid collection 6. After the liquid is separated, the material is discharged from the system through the solid discharge 7.

[0017] Factors affecting the solid-liquid separation effect include: system temperature, liquid properties, etc. The specific parameters are adjusted according to the properties of the liquid and...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com