9000UV vacuum coating paint

A vacuum coating and vacuum electroplating technology, which is applied in the industrial field, can solve the problems of high comprehensive construction cost, incompatible with ecological environment protection, low energy utilization rate, etc., and achieve the effects of beautiful appearance, fast curing speed and easy operation.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

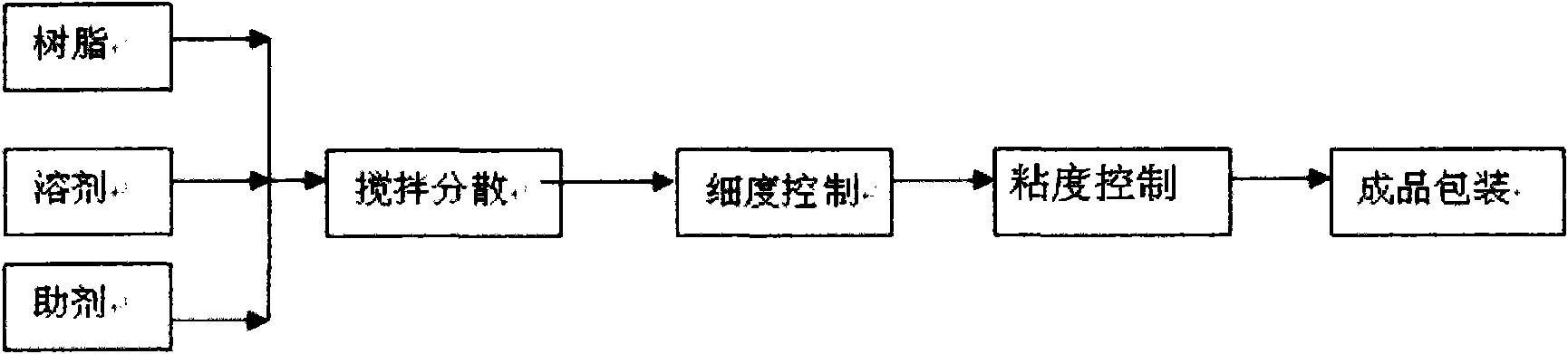

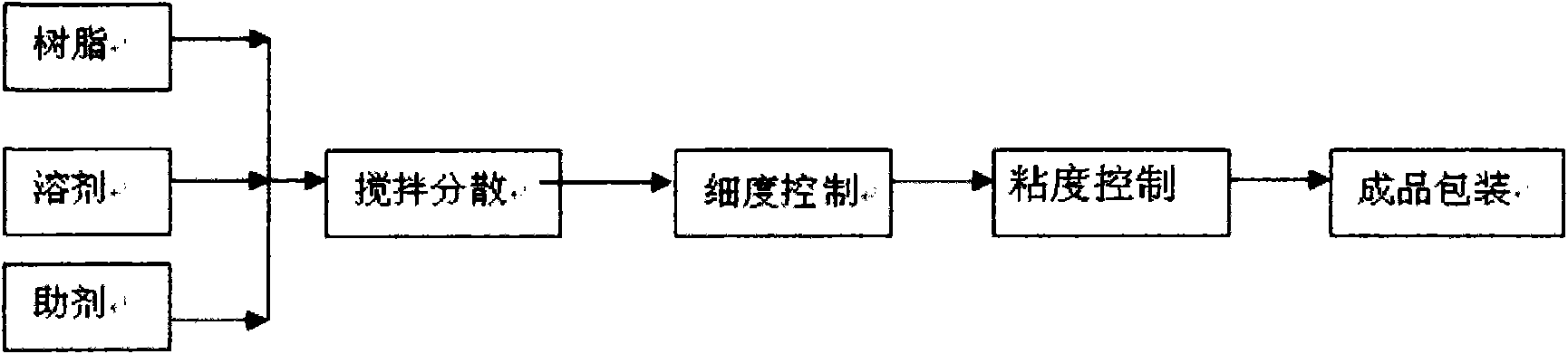

[0011] see figure 1 , the specific implementation method adopts the following technical scheme: it is divided into three types: primer, intermediate paint and top paint, and its preparation process is: put liquid resin, organic solvent, photosensitizer and auxiliary agent into the tank for stirring Disperse, and then test the fineness and viscosity. After the test meets the requirements, it can be packaged as a finished product.

[0012] The formula of the primer consists of: n-butyl acetate, ethyl fat, diisobutyl ketone, toluene, 621A-80, UV-3000, AB-5005, 184 initiator, SR-351, 1173, BYK-306 , Chlorine vinegar;

[0013] The formulation of the intermediate paint consists of: 6071, MF-300A, 184 initiator, photoinitiator, BYK-306, SR-506, HEMA, boiling oil and water.

[0014] The formulation of the top paint is composed of: DPHA monomer, UV-7600B, MF-600, MF-300A, 184 initiator, photoinitiator, HEMA, resin CD-9051, boiling oil and water.

[0015] The construction process of ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com