Technology for recycling high-purity cut silicon powder by dry method

A silicon powder and high-purity technology, applied in the fields of physics and semiconductor materials, can solve problems such as environmental pollution, large energy consumption, and long process cycle, and achieve the effects of purifying the environment, reducing energy consumption, and improving efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

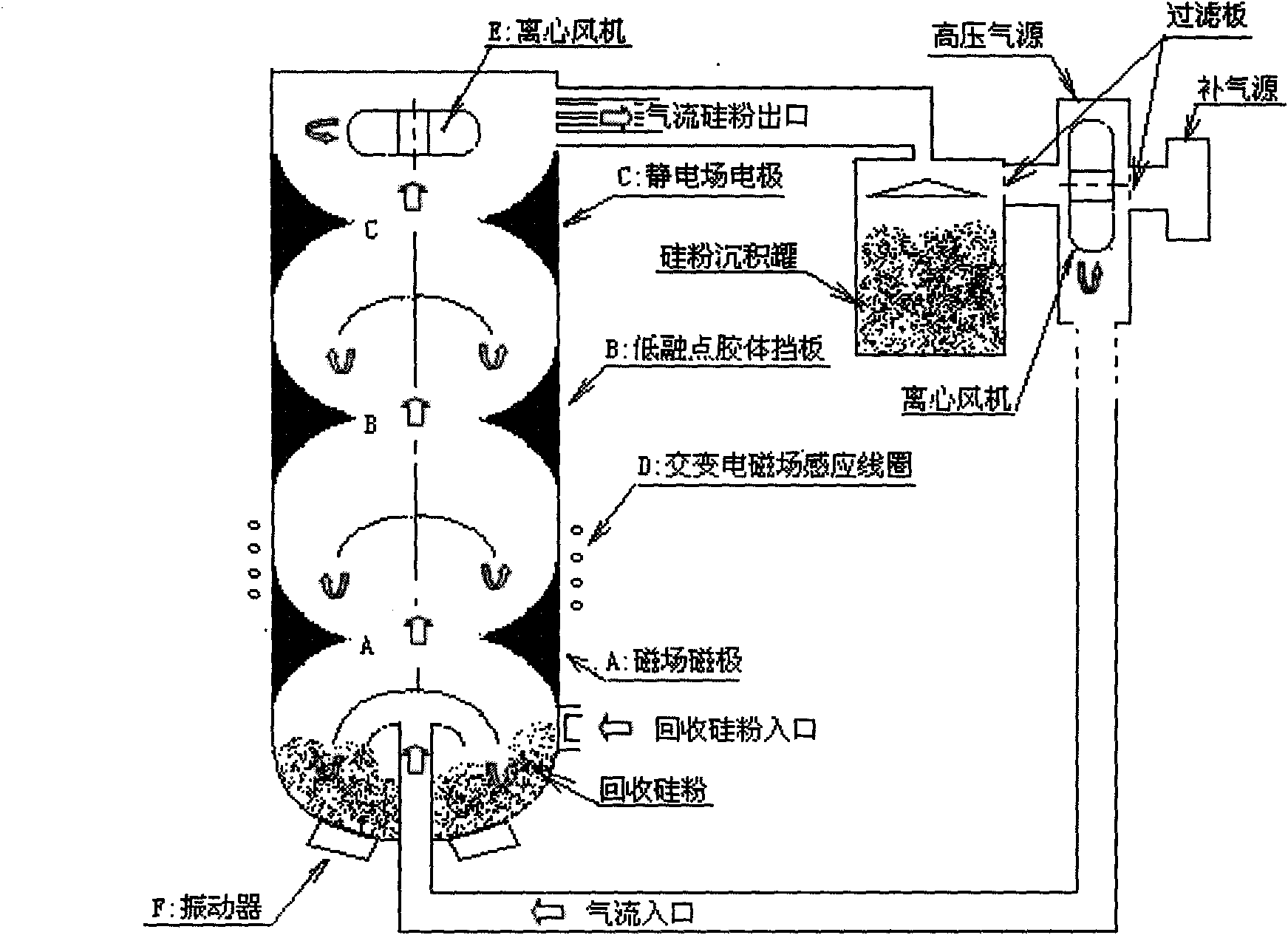

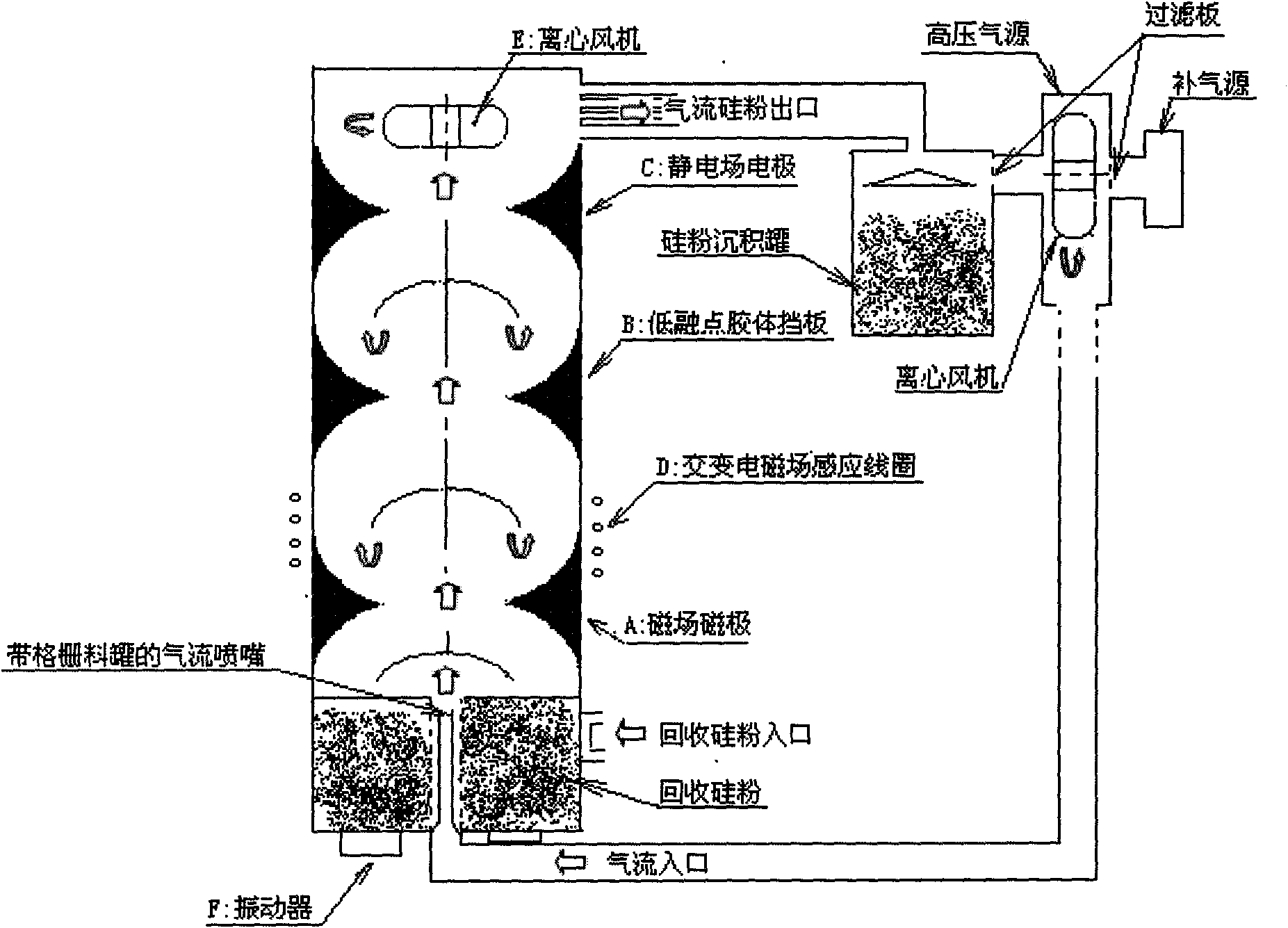

[0029] Add the silicon powder to be recovered from the "recovered silicon powder inlet", seal and close the feeding window, start the high-pressure air pump, compress the purified clean gas and spray it in through the "gas inlet".

[0030] The high-speed airflow blows the silicon powder and other solid powder impurities injected into the bottom into smoke and suspends in the three-dimensional space, and separates into individual particles to move with the airflow. At the same time, it is equipped with mechanical vibration F to facilitate powder separation.

[0031] (1). The dust airflow with various material components flows in a specific pipeline. When it passes near the magnetic pole A, the ferromagnetic particles mixed in are captured and adsorbed by the magnetic pole A in the strong magnetic field and fixed in a specific area. Ferromagnetic impurities separated from the air stream.

[0032] (2). When the air flow passes through the alternating electromagnetic field D in t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com