Photocatalyst, preparation method and application thereof

A photocatalyst, a technology for refining diatomite, applied in catalyst activation/preparation, chemical instruments and methods, physical/chemical process catalysts, etc. Broad prospects for development and the effect of preventing agglomeration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

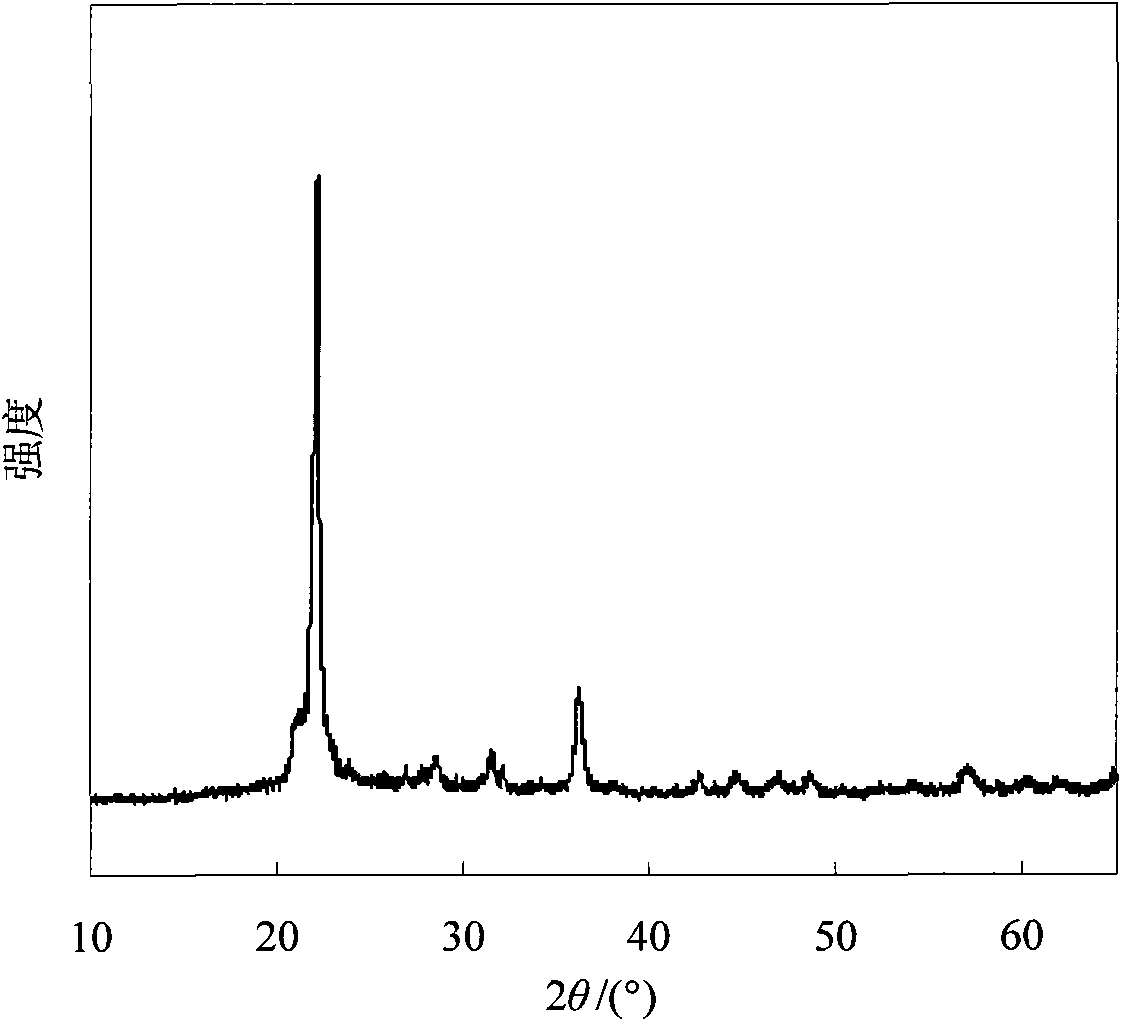

[0026] 1. Refining of diatomite: take 50g of diatomite and 500g of sulfuric acid solution (mass concentration 40%), fully stir and react in a water bath at 100°C for 4h, then add 250g of water to dilute and react for 1h, then filter the diatomite, Washed, dried, and calcined at 550°C for 5h in a muffle furnace. The resulting refined diatomaceous earth SiO 2 (see figure 1 ) with a mass fraction of 91.86%, the main impurity Al 2 o 3 1.72%, Fe 2 o 3 was 1.72%.

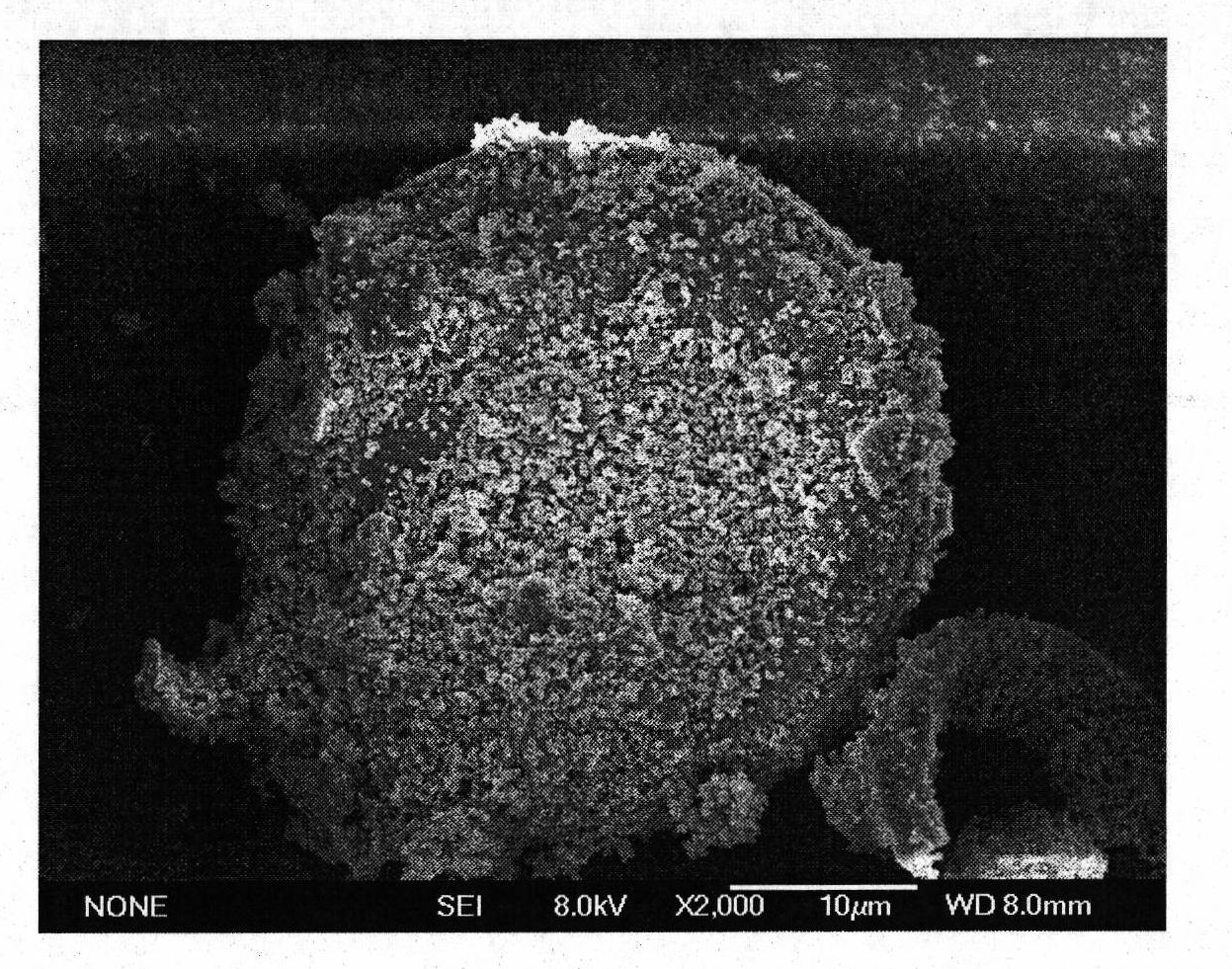

[0027] 2. Preparation of the catalyst: under ultrasonic frequency 40KHz radiation, add 1.0g CuCl and 0.5g sodium dodecylbenzenesulfonate to 100mL, 5.0mol / L NaCl solution and stir evenly, then add 1.0mol / L Na 3 PO 4 10mL of the solution and 1.5g of refined diatomaceous earth were obtained to obtain a yellow suspension, which was stirred for half an hour to make the nano-Cu 2 O was evenly attached to the surface of diatomaceous earth, and then the resulting solution was suction-filtered, and the obtained product wa...

Embodiment 2

[0032] Preparation method: under ultrasonic frequency 60KHz radiation, add 0.8g CuCl and 0.4g sodium dodecylbenzenesulfonate to 100mL, 4.8mol / L NaCl solution and stir evenly, then add 1.0mol / L NaCl 3 PO 4 Solution 8mL and 1.0g refined diatomaceous earth to obtain a yellow suspension; stir the yellow suspension for 1.0h to make the nano-Cu 2 O is evenly attached to the surface of diatomaceous earth, and then the resulting solution is suction filtered, then washed with distilled water for 4 times, and then washed once with 15mL acetone and 15mL ether, and the washed product is transferred to a rotary evaporator, and vacuum evaporated at 40°C. dry to obtain nano cuprous oxide / diatomaceous earth carrier photocatalyst.

[0033] The refined diatomite is to take sulfuric acid solution and diatomite at a liquid-solid mass ratio of 15:1, fully stir and react in a water bath at 100° C. for 3.5 hours, and wait for use; After adding the reactants obtained above to react for 2 hours, dia...

Embodiment 3

[0035] Preparation method: under ultrasonic frequency 50KHz radiation, add 1.2g CuCl and 0.6g sodium dodecylbenzenesulfonate to 100mL, 4.9mol / L NaCl solution and stir evenly, then add 1.0mol / L NaCl 3 PO 4 Solution 9mL and 2.0g refined diatomaceous earth to obtain a yellow suspension; stir the yellow suspension for 1.0h to make the nano-Cu 2 O is evenly attached to the surface of diatomaceous earth, and then the resulting solution is suction filtered, then washed with distilled water for 5 times, and then washed once with 25mL acetone and 25mL ether, and the washed product is transferred to a rotary evaporator and vacuum evaporated at 45°C. dry to obtain nano cuprous oxide / diatomaceous earth carrier photocatalyst.

[0036] The refined diatomaceous earth is to take sulfuric acid solution and diatomite at a liquid-solid mass ratio of 13:1, fully stir and react in a water bath at 100°C for 4.5h, and set aside for use; then press water to solid mass ratio of 18:1 After adding the...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com