On-site absorption spectrum gas analysis system

A gas analysis system and analysis system technology, applied in the field of spectrum analysis, can solve the problems of increasing the complexity of the system, increasing the number of reflective surfaces, increasing the optical noise, etc., to reduce the optical etalon noise, reduce the optical etalon noise, and improve the measurement accuracy. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

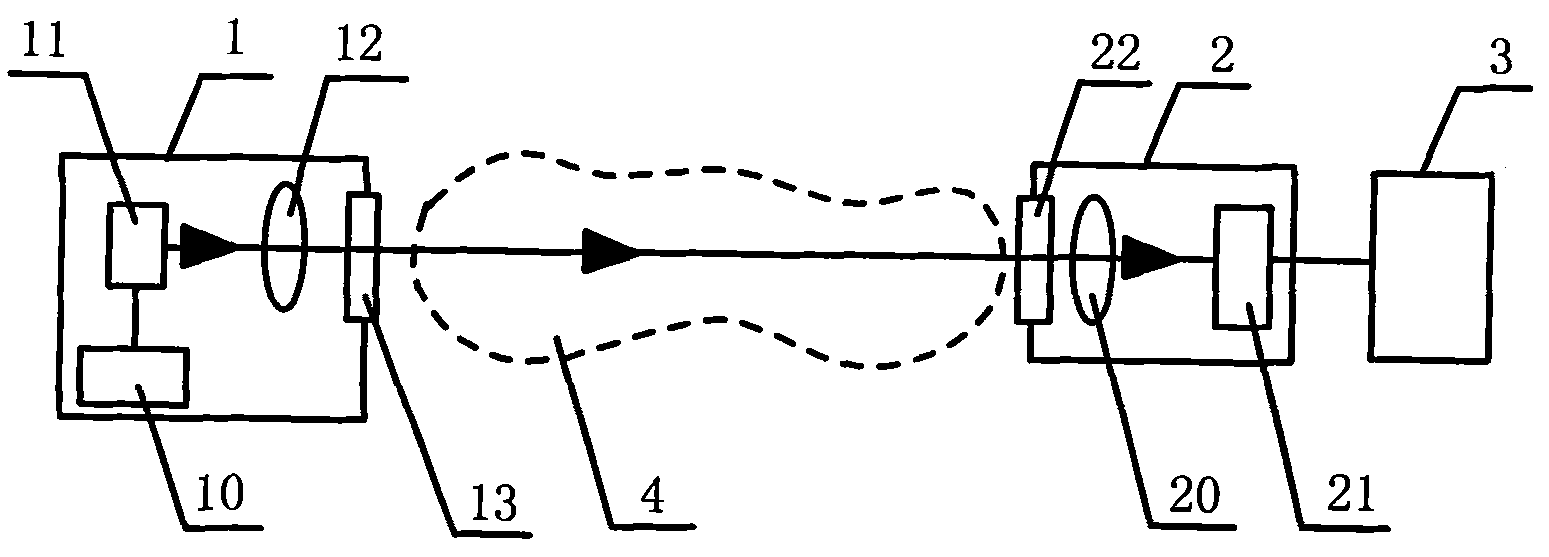

[0054] Such as Image 6 As shown, a semiconductor laser absorption spectrum trace water analysis system is used to detect the concentration of trace water in the measured gas 4 and also meet the explosion-proof requirements. The analysis system includes a light emitting unit 1 , a light receiving unit 2 and a signal analysis unit 3 , and the light emitting unit 1 and the light receiving unit 2 are installed on both sides of the measured gas 4 .

[0055] The light emitting unit 1 includes a housing, a semiconductor laser 11 and its driving circuit 10, a first converging lens 14 and a sleeve 5, and the semiconductor laser 11 and the first converging lens 14 are installed in the sleeve 5, wherein The semiconductor laser 11 is mounted on a laser mount 15 . The driving circuit 10 of the semiconductor laser 11 is installed in the casing. The sleeve and the first converging lens 14 are sealed by a sealing member such as an O-ring 16 , and a lens fastener 17 is installed at the fron...

Embodiment 2

[0074] Such as Figure 7 As shown, a semiconductor laser absorption spectrum trace hydrogen sulfide analysis system is used to detect the concentration of trace hydrogen sulfide, and it also meets the explosion-proof requirements. The difference with embodiment 1 is:

[0075] 1. If Figure 8 As shown, a calibration chamber 6 is provided at the spherical end of the second converging lens. One end of the calibration chamber 6 is closed and has a bevel, and the other end is open, and is sealed and connected with the spherical end of the second converging lens. The calibration chamber 6 is closed with carbon monoxide gas of known concentration.

[0076] 2. The A-A section of the middle part of the first and second converging lenses is a square, such as Figure 9 As shown, the diameter of the smallest covering circle of the square is 40 mm.

[0077] 3. The calibration chamber is filled with carbon monoxide gas of known concentration.

[0078] 4. The central wave number used is...

Embodiment 3

[0080] A semiconductor laser absorption spectrum trace water analysis system is used to detect the concentration of trace gaseous water and also meets the explosion-proof requirements. The difference with embodiment 1 is:

[0081] 1. If Figure 10As shown, the light-emitting unit 1 and the light-receiving unit are on the same side of the measured gas 4, and the light emitted by the light-emitting unit 1 passes through the converging lens 14, the calibration chamber 7, and the measured gas 4 and is reflected by the mirrors 30 and 31. After that, it passes through the measured gas 4, the converging lens 23, and finally is received by the photoelectric sensor 21.

[0082] 2. The A-A section of the middle part of the first and second converging lenses is elliptical, such as Figure 11 As shown, the diameter of the minimum coverage circle of the ellipse is 45mm, and the thickness of the first and second converging lenses (the chief ray optical path of the laser beam in the first ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com