Splicing device and method of crystal bars with equal length or square crystal ingots with equal length

A splicing device and equal-length technology, applied in chemical instruments and methods, crystal growth, post-processing details, etc., can solve problems that are not easy to standardize and scale production, equal-length wafer rods or equal-length ingots have poor concentricity, Alignment and other problems, to achieve the effect of easy standardization and large-scale production, short splicing time, and good concentricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

specific Embodiment

[0108] 1. Use a flat ruler to detect the height of the two end faces of the spliced short equal-diameter wafer rod (or equilateral square ingot), and confirm that the deviation is ≤ 2mm (also known as horseshoe cut) to be qualified. And according to the equal length requirements of the multi-wire cutting machine, short equal-diameter ingots (or equilateral square ingots) of corresponding heights are selected for use.

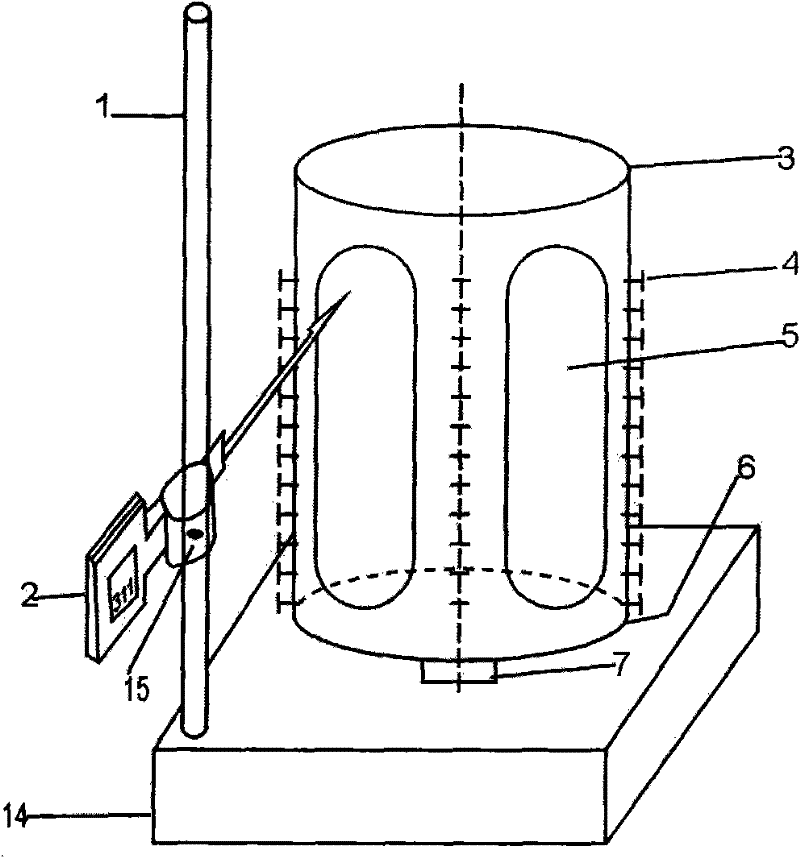

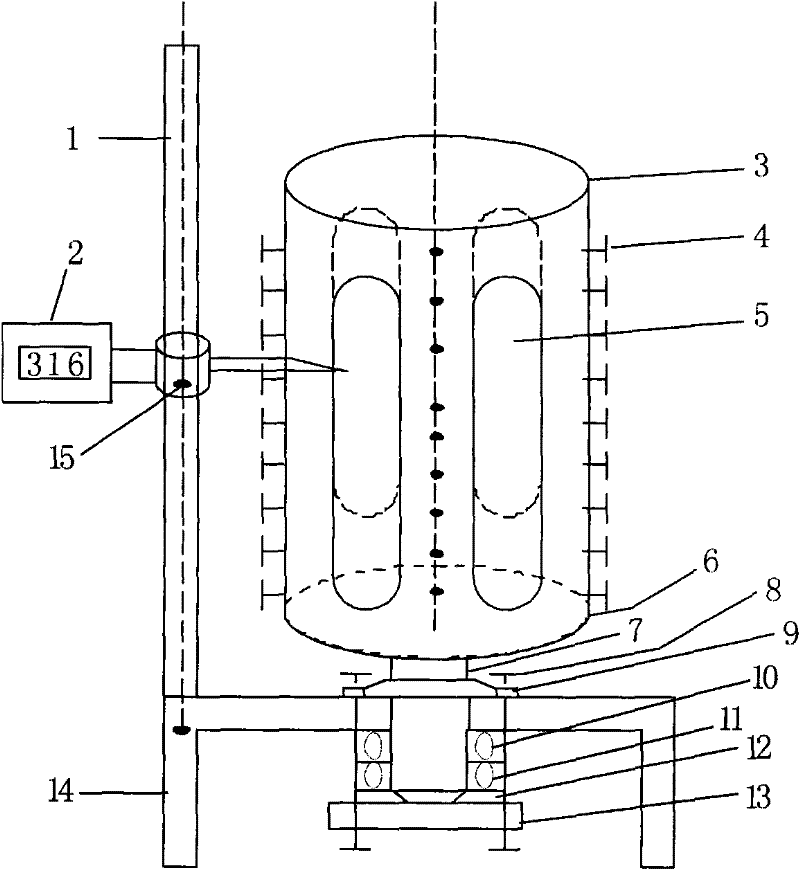

[0109]2. Put the polyethylene air cushion 25 of the suction tool on the surface to be bonded, press down the air handle 17 firmly, so that the suction tool and the short round crystal rod (or equilateral square ingot) are tightly sucked. After confirmation, Lift it from the mouth of the barrel and put it into the center of the bottom of the barrel, slide down the digital display vernier 2 on the concentricity test rod 1, enter the pointer from the symmetrical concentricity test hole 5 carrying the symmetrical barrel, read and remember this reading, Turn the co...

PUM

| Property | Measurement | Unit |

|---|---|---|

| length | aaaaa | aaaaa |

| diameter | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com