Device for preparing microstep reflector structure by using a plurality of cuboid substrates

A technology of stepped structure and mirror, applied in the direction of mirrors, etc., can solve the problems of difficulty in guaranteeing horizontal accuracy, poor accuracy and repeatability, low control accuracy of step height, etc., and achieves the effect of high flatness and improved roughness accuracy.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

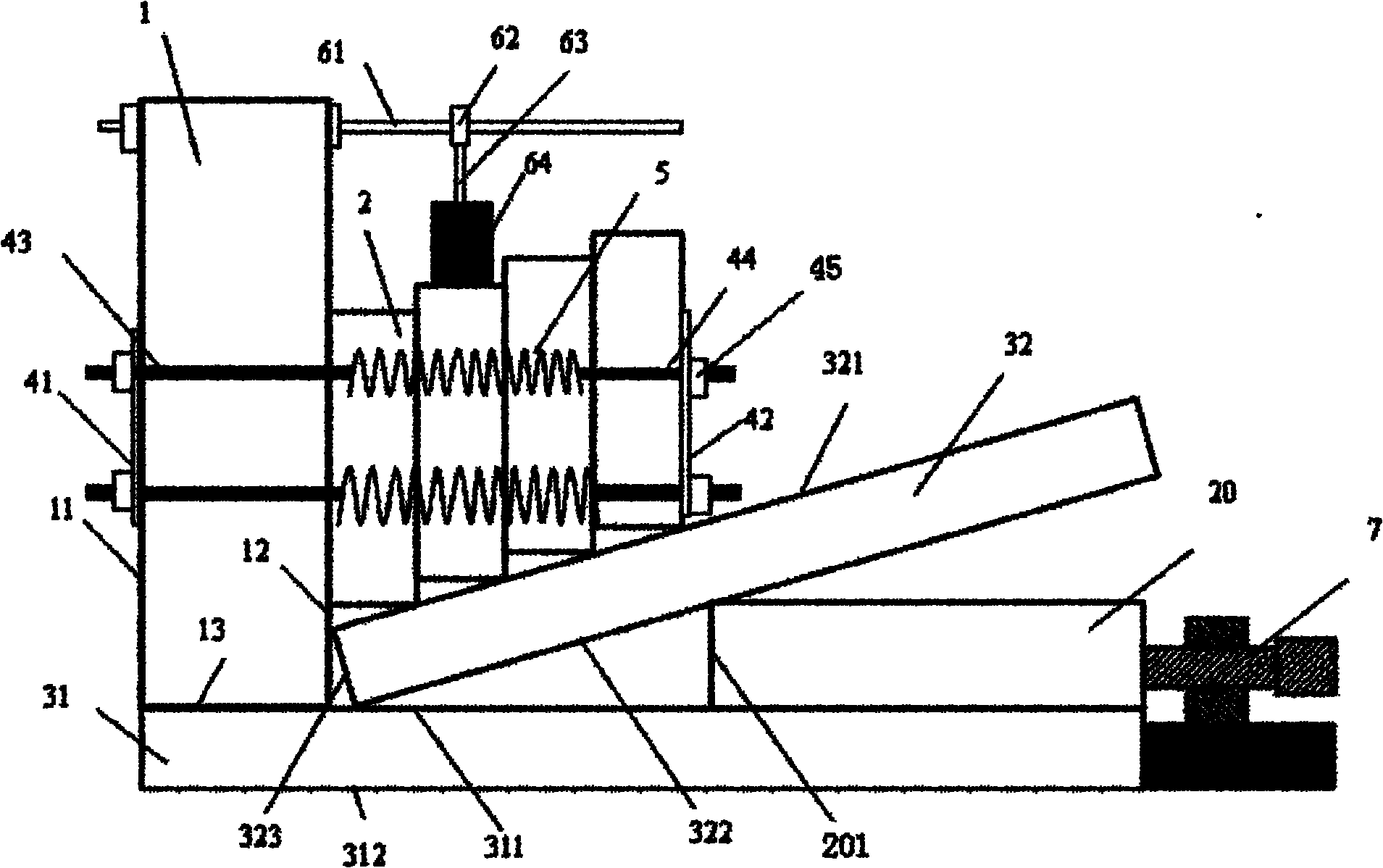

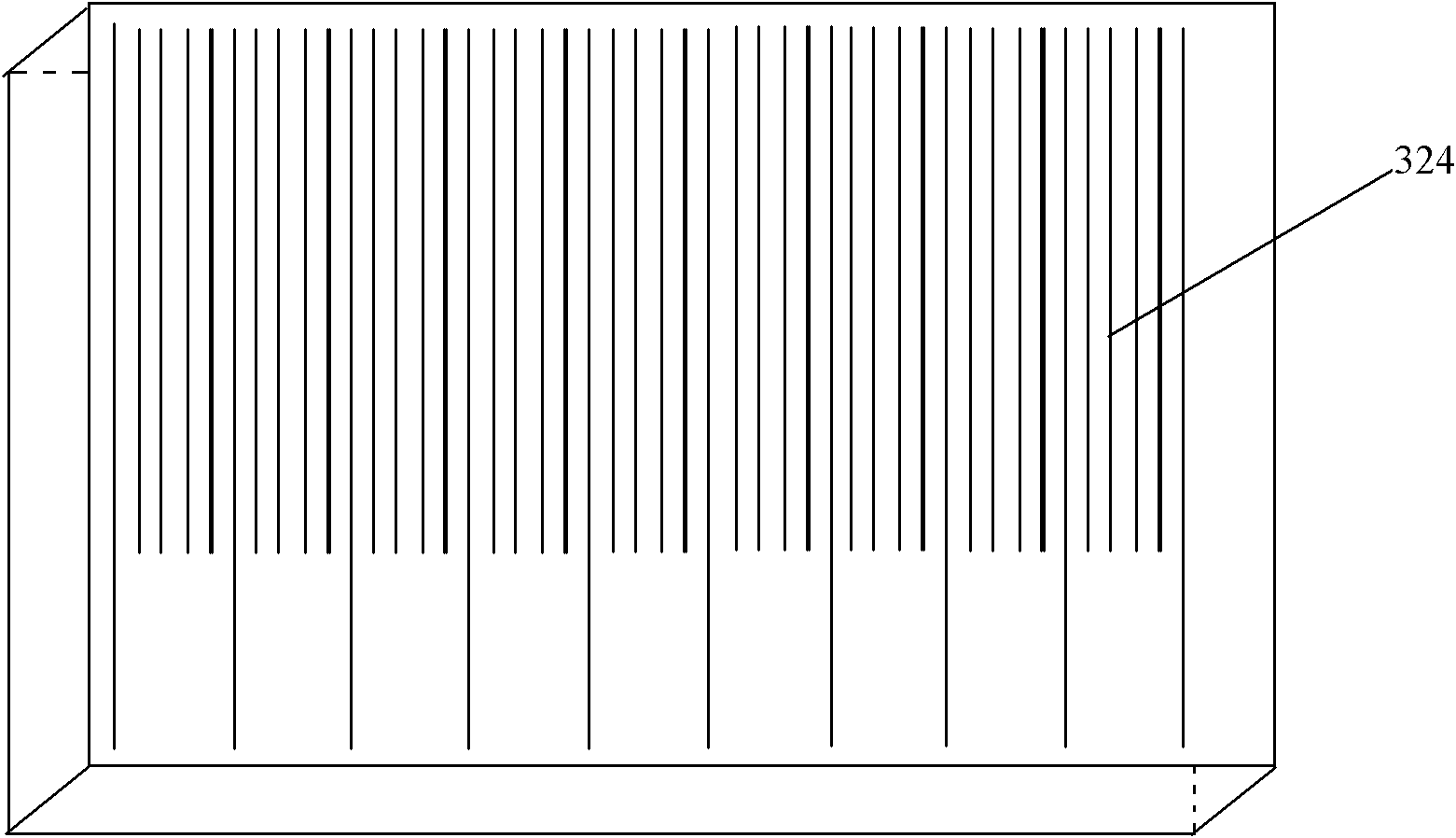

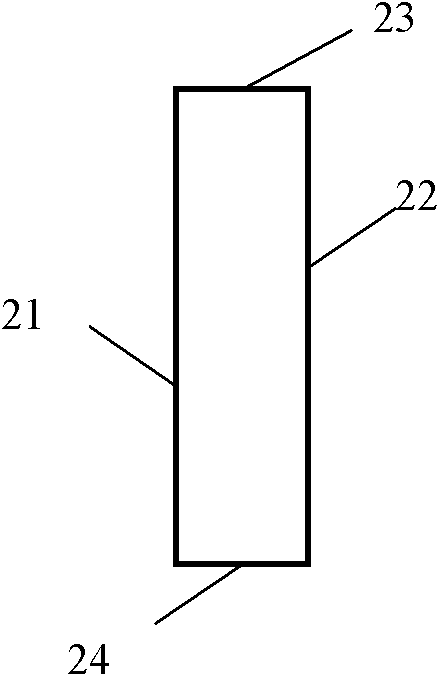

[0015] Such as figure 1 , 2 As shown, the present invention utilizes a plurality of rectangular parallelepiped substrates to make the device of the step structure of the micro-step reflector including a standard block 1 , a first base 31 , a second base 32 , a micro-adjustment frame 7 , and a sliding adjustment plate 20 . The standard block 1 is fixed on the first base 31 near the left side, and the micro-adjustment frame 7 is fixed on the right side of the first base 31; the sliding adjustment piece 20 is located on the first base 31 near the right side, and can be Under the action of the micro-adjustment frame 7, it moves on the first base 31; one end of the second base 32 with a metal scale line 324 is placed at the contact angle between the standard block 1 and the first base 31, and the other end is suspended on the sliding adjustment piece 20 above. The present invention also includes a vertical extruding assembly and a horizontal extruding assembly; the vertical extru...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com