Manufacturing method and device of light-focusing Fresnel lens

The technology of a Fresnel lens and a manufacturing method, which is applied in the field of manufacturing a concentrating Fresnel lens, can solve the problems of difficult removal of air holes, slow production speed, and difficult process, and achieve fast production speed, less air holes, and simple process Effect

Inactive Publication Date: 2011-06-15

BEIJING UNIV OF TECH

View PDF4 Cites 10 Cited by

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

The embodiment of the present invention provides a method and device for manufacturing a concentrating Fresnel lens, which is used to solve the problem of difficult process caused by the need for secondary forming in the first prior art, and at the same time solve the problem provided by the second prior art. The production method has the problems of slow production speed, difficult demoulding and difficult removal of pores

Method used

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

View moreImage

Smart Image Click on the blue labels to locate them in the text.

Smart ImageViewing Examples

Examples

Experimental program

Comparison scheme

Effect test

Embodiment Construction

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Login to View More

Abstract

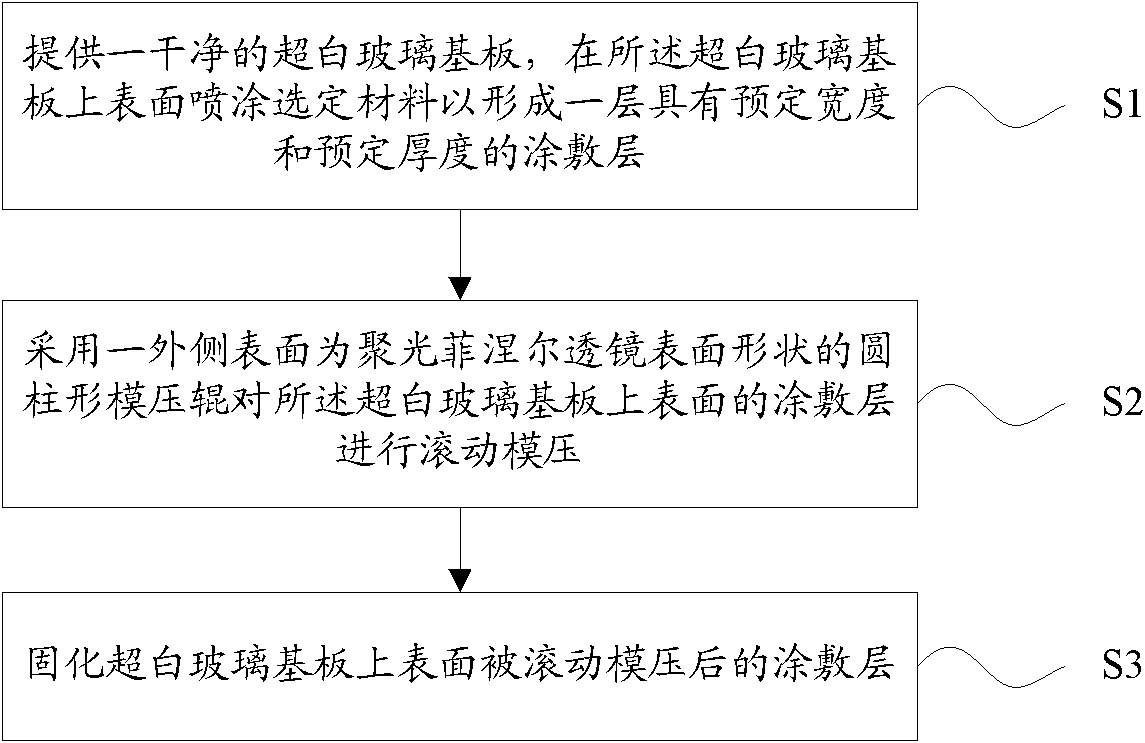

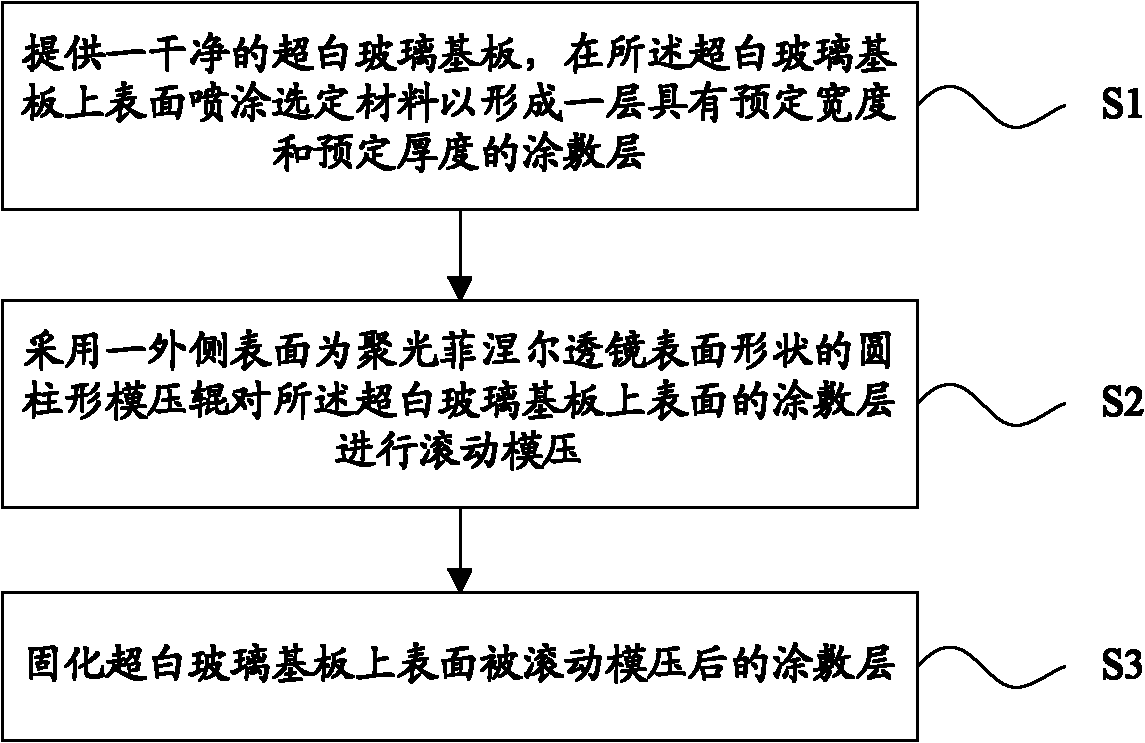

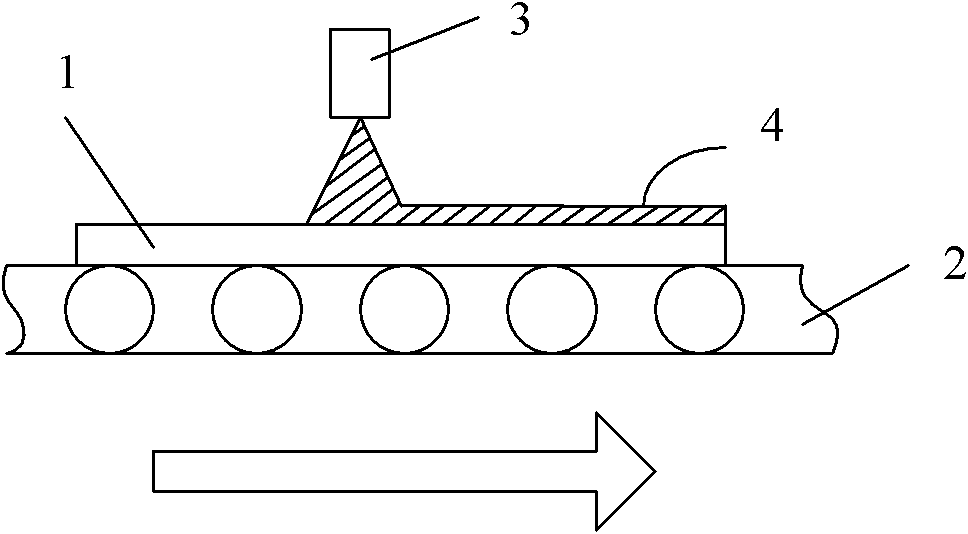

The invention discloses a manufacturing method and device of a light-focusing Fresnel lens. The method provided by the invention comprises the following steps: (1) providing a clean and ultrawhite glass substrate and spraying a selected material on the upper surface of the ultrawhite glass substrate so as to form a coating layer with a preset width; (2) adopting a cylindrical die-pressing roller of which one outer side surface is in the shape of the surface of the light-focusing Fresnel lens to carry out rolling and die-pressing on the coating layer; and (3) curing the coating layer after being rolled and die-pressed. In the manufacturing method of the light-focusing Fresnel lens provided by the invention, the production speed is high, the demoulding is simple, the produced Fresnel lens does not have air holes almost and the practicability is strong.

Description

Manufacturing method and device of a concentrating Fresnel lens technical field The invention relates to the field of concentrating photovoltaics, in particular to a method and device for manufacturing a concentrating Fresnel lens. Background technique With the depletion of global fossil energy and the enhancement of human awareness of environmental protection, solar power generation with photovoltaics as the core has developed rapidly in recent years. However, the price of solar power generation systems has remained high, mainly due to the low density of solar energy and the low conversion efficiency of solar cells. In order to reduce the price of solar power generation systems, high-power concentrating solar photovoltaic power generation technology has emerged as the times require. Concentrating photovoltaic power generation technology combines traditional solar photovoltaic technology with large-scale concentrated solar power plants, which can greatly enhance solar ene...

Claims

the structure of the environmentally friendly knitted fabric provided by the present invention; figure 2 Flow chart of the yarn wrapping machine for environmentally friendly knitted fabrics and storage devices; image 3 Is the parameter map of the yarn covering machine

Login to View More Application Information

Patent Timeline

Login to View More

Login to View More Patent Type & Authority Applications(China)

IPC IPC(8): G02B3/08G02B1/00H01L31/052H01L31/055

CPCY02E10/50Y02E10/52

Inventor 王智勇卫明

Owner BEIJING UNIV OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com